A quartz crucible forming mold

A technology for forming molds and quartz crucibles, applied in glass forming, manufacturing tools, glass manufacturing equipment, etc., can solve the problems of inability to use high-quality domestic quartz sand, difficult to remove metal impurities, poor high temperature resistance of molds, etc. Heat loss, tight bonding, improved vacuum effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

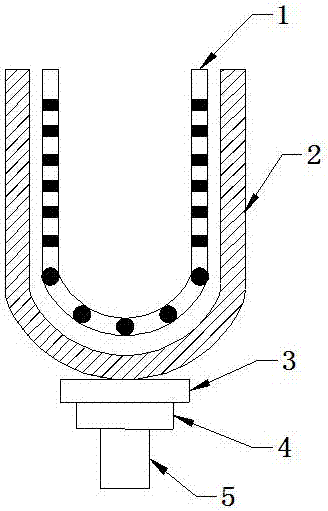

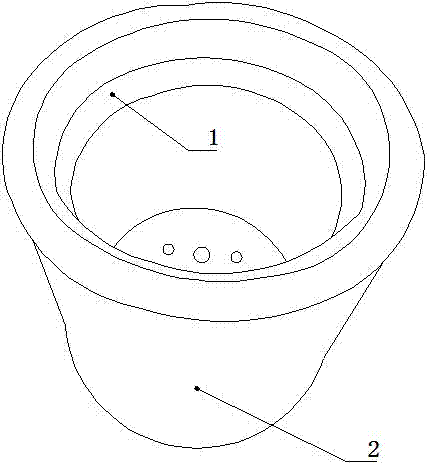

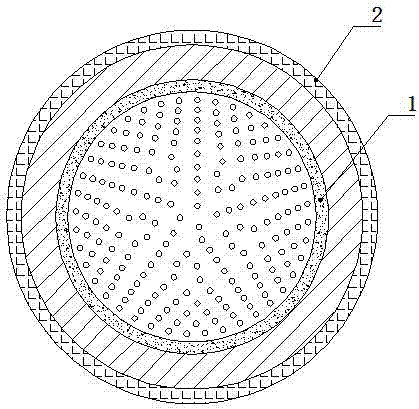

[0027] Such as figure 1 , figure 2 with image 3 As shown, a quartz crucible forming mold includes a metal alloy mold 1, an outer mold 2, a porous alloy base 3, a rotary table 4, and a rotating shaft 5. The outer layer of the metal alloy inner mold 1 is covered with an outer mold 2, The bottom of the metal alloy mold 1 is equipped with a porous alloy base 3, and the porous alloy base 3 is placed on a rotating table 4, and a rotating shaft 5 is arranged under the rotating table 4. Wherein, a cavity is formed between the metal alloy mold 1 and the outer mold 2, and a vacuum pipeline is installed on the rotary table, and the vacuum pipeline communicates with the cavity and passes through the outer mold 2 and the central hole of the metal alloy mold 1, the vacuum pipelines are assembled into a vacuum pipeline inside the rotating shaft 5 and connected to the external air pump.

[0028] When the mold is in use, the air pump first pumps air to the metal alloy mold system through ...

Embodiment 2

[0032] Such as figure 1 , figure 2 with image 3As shown, a quartz crucible forming mold includes a metal alloy mold 1, an outer mold 2, a porous alloy base 3, a rotary table 4, and a rotating shaft 5. The outer layer of the metal alloy inner mold 1 is covered with an outer mold 2, The bottom of the metal alloy mold 1 is equipped with a porous alloy base 3, and the porous alloy base 3 is placed on a rotating table 4, and a rotating shaft 5 is arranged under the rotating table 4. Wherein, a cavity is formed between the metal alloy mold 1 and the outer mold 2, and a vacuum pipeline is installed on the rotary table, and the vacuum pipeline communicates with the cavity and passes through the outer mold 2 and the central hole of the metal alloy mold 1, the vacuum pipelines are assembled into a vacuum pipeline inside the rotating shaft 5 and connected to the external air pump.

[0033] The metal alloy mold 1 is provided with a plurality of micropores.

[0034] The cold water ci...

Embodiment 3

[0039] Such as figure 1 , figure 2 with image 3 As shown, a quartz crucible forming mold includes a metal alloy mold 1, an outer mold 2, a porous alloy base 3, a rotary table 4, and a rotating shaft 5. The outer layer of the metal alloy inner mold 1 is covered with an outer mold 2, The bottom of the metal alloy mold 1 is equipped with a porous alloy base 3, and the porous alloy base 3 is placed on a rotating table 4, and a rotating shaft 5 is arranged under the rotating table 4. Wherein, a cavity is formed between the metal alloy mold 1 and the outer mold 2, and a vacuum pipeline is installed on the rotary table, and the vacuum pipeline communicates with the cavity and passes through the outer mold 2 and the central hole of the metal alloy mold 1, the vacuum pipelines are assembled into a vacuum pipeline inside the rotating shaft 5 and connected to the external air pump.

[0040] The metal alloy mold 1 is provided with a plurality of micropores.

[0041] The cold water c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com