Coating equipment and coating method for annular aluminum powder coating in bottle mouth sealing gasket

A ring-shaped, aluminum powder technology, applied in coatings, devices for coating liquid on the surface, etc., can solve problems such as the inability to replace aluminum foil with ring-shaped aluminum powder coatings, achieve novel structural design, reduce manufacturing costs, and save resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

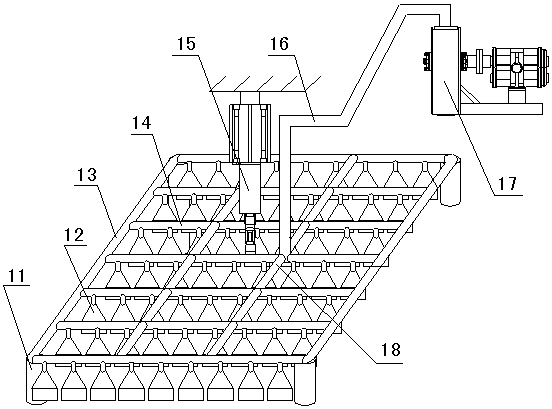

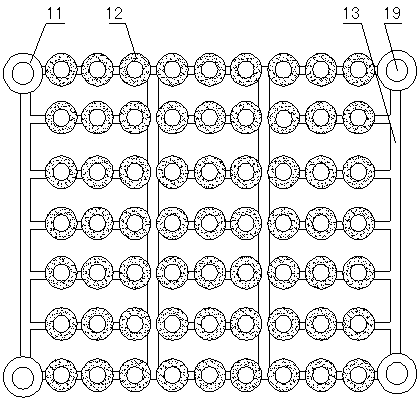

[0013] Embodiment 1: with reference to attached Figure 1-3 . A kind of coating equipment for the ring-shaped aluminum powder coating in the sealing pad of the bottle mouth, including a PLC controller, the four corners of the lifting frame 13 are equipped with linear bearing lifting seats, and the two ends of a plurality of fluid conduits 14 are welded to the inner side of the lifting frame 13 at equal intervals , a plurality of fluid conduits 14 are communicated through a fluid branch pipe 18, and the fluid branch pipe 18 is communicated with the aluminum powder pressure storage tank 17 through a fluid main pipe 16, and a plurality of annular bottle mouth coating heads 12 are equidistant from the fluid outlets of the plurality of fluid conduits 14 respectively. Connected, the piston head in the cylinder 15 is connected with the lifting frame 13 and drives the lifting frame 13 and a plurality of ring-shaped bottle mouth coating heads 12 to lift. The linear bearing lifting sea...

Embodiment 2

[0014] Embodiment 2: On the basis of embodiment 1, a kind of coating method that is used for the coating equipment of annular aluminum powder coating in the bottle mouth seal pad, comprises PLC controller, needs to be coated on polyethylene foam layer 2 sides When the annular aluminum powder coating is 3, the PLC controller instructs the aluminum powder pressure storage tank 17 to be in a working state under pressure. When the polyethylene foam layer 2 is sent to the work surface, the PLC controller detects the polyethylene foam through the detection probe After the layer 2 reaches the set position, the instruction cylinder 15 drives the lifting frame 13 and the multiple ring-shaped bottle mouth coating heads 12 on the lifting frame to descend. At the moment of contact, multiple ring-shaped bottle mouth coating heads 12 coat the aluminum powder on the surface of the polyethylene foam layer 2. At this time, the PLC controller instructs the cylinder 15 to drive the lifting frame ...

Embodiment 3

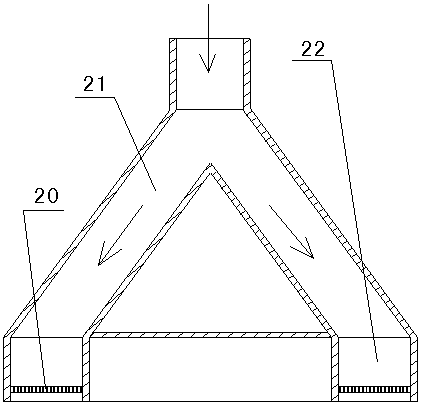

[0015] Embodiment 3: with reference to attached Figure 4 with 5 . On the basis of Examples 1 and 2, a method for making a ring-shaped bottle mouth electromagnetic induction heating sealing pad, the PET layer 1 is covered with a polyethylene foam layer 2, and a plurality of regularly arranged one or more rows of ring-shaped bottle mouths The coating head passes through the lifting frame 13 under the action of the cylinder 15. At the same time, the multi-row ring-shaped bottle mouth coating head coats the aluminum powder viscose solution on the polyethylene foam layer, and the entire polyethylene foam layer is coated. Finally, the heat-sealing layer 4 is compounded on the annular aluminum powder coating 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com