Continuous steam recompression evaporation system using flash steam waves

A vapor recompression and evaporation system technology, which is applied in multiple-effect evaporation, evaporator accessories, etc., can solve the problems of low ejector boosting efficiency, insufficient use of secondary steam latent heat, and insignificant energy-saving effect, etc. Achieve excellent performance with liquid, wide application range and small structure size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

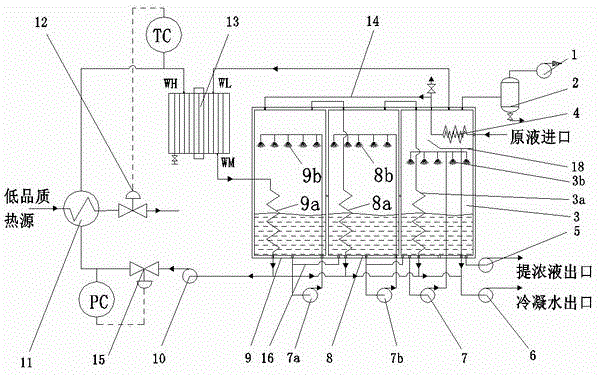

[0021] Example 1 Using saturated or superheated liquid water to complete the recompression of secondary steam in a flash wave supercharger.

[0022] figure 1 A flash wave vapor recompression continuous evaporation system is shown. In the figure, the flash wave vapor recompression continuous evaporation system includes a three-effect evaporator, concentrated liquid pump 5, condensate pump 6, heat source heat exchanger 11, and the three-effect evaporator consists of a first-effect evaporator 9 and a second-effect evaporator 8 Composed with the final effect evaporator 3, the bottom of the first effect evaporator 9 and the secondary effect evaporator 8, and the bottom of the secondary effect evaporator 8 and the final effect evaporator 3 are connected to each other by a communication pipe 16. The first effect circulation pump 7a of the first effect evaporator 9 is used to connect the first effect liquid uniform distributor 9b in the first effect evaporator 9, and the second effec...

Embodiment 2

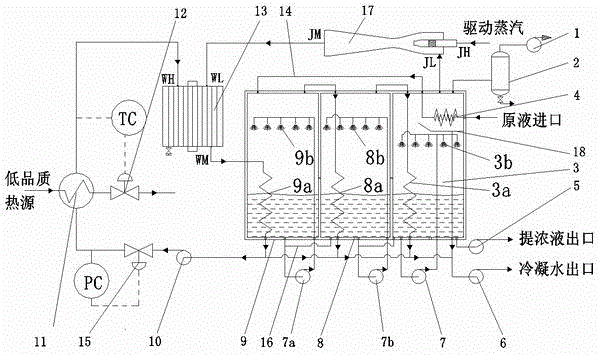

[0027] Example 2 Combined use of steam ejector and flash wave supercharger to complete the recompression of secondary steam.

[0028] figure 2 A continuous evaporation system combining thermal vapor recompression with flash wave vapor recompression is shown. figure 2 and figure 1 The difference is that the upper space of the final effect evaporator 3 is connected to the low-pressure steam inlet JL of the steam ejector 17 by a pipeline, and the boost outlet JM of the steam ejector 17 is connected to the low-pressure steam inlet WL of the flash wave supercharger 13 , driving steam to enter from the high-pressure inlet JH of the steam injector 17.

[0029] In each effect evaporator, the heat exchange on the evaporating side adopts a forced circulation liquid distributor to complete the liquid distribution. In the co-current and co-current feeding methods, the feed liquid of the front effect and the after effect is transported by the pressure difference; in the counter-curren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com