Locking screw provided with porous surface and used for bone connection and fixation

A locking screw, porous surface technology, applied in medical science, prosthesis, etc., can solve the problem of locking screw and bone tightly combined without loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

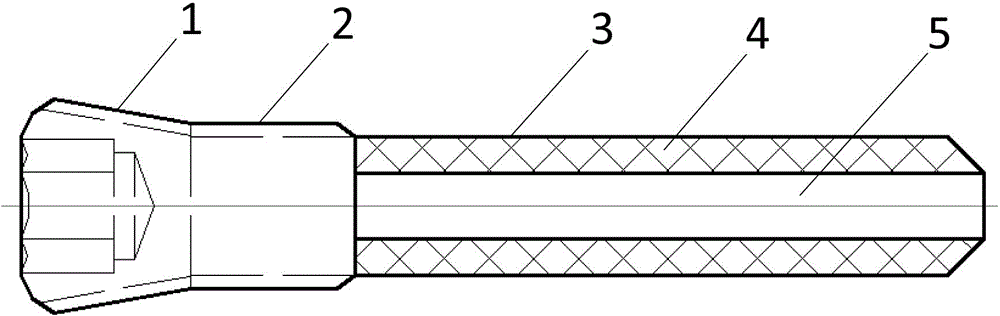

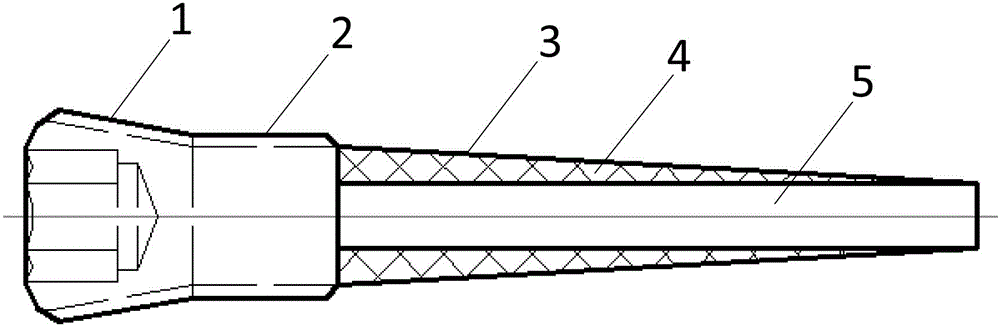

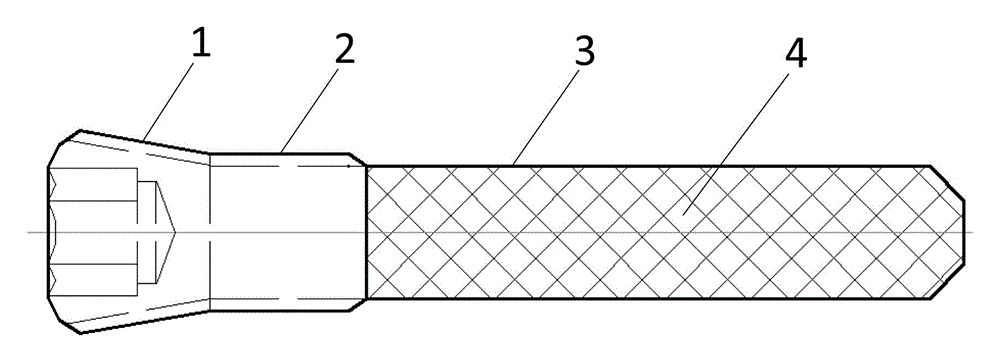

[0015] figure 1 It is a structural schematic diagram of a locking screw with a porous surface for bone connection and fixation. The diagram shows a locking screw with a porous surface for bone connection and fixation, including a screw head 1, a screw neck 2, and a shaft 3, and the screw head 1, screw neck 2, and shaft 3 are sequentially arranged from top to bottom Connected into one body, it is characterized in that: the screw head 1 is in the shape of a round table with a large upper and a lower area, the screw neck 2 is cylindrical, the lower bottom surface of the circular table is equal in area to the cylinder, and the screw head 1 Threads are provided on the side surface of the screw neck 2, and a porous layer 4 with a pore diameter of 50-800 μm is provided on the side of the shaft rod 3.

[0016] The shaft center of the shaft 3 is a solid layer 5, and the solid layer 5 is placed in the porous layer 4 ( figure 1 Both the medium porous layer 4 and the solid layer 5 are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com