Lithium battery tab hot press molding method

A technology of hot pressing and lithium batteries, which is applied to battery components, circuits, electrical components, etc., can solve the problems of inability to monitor and control, long heating time of heated objects, and large high-frequency fluctuation range, etc., to achieve stable heating temperature Reliable, shortened hot press forming time, large heating area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

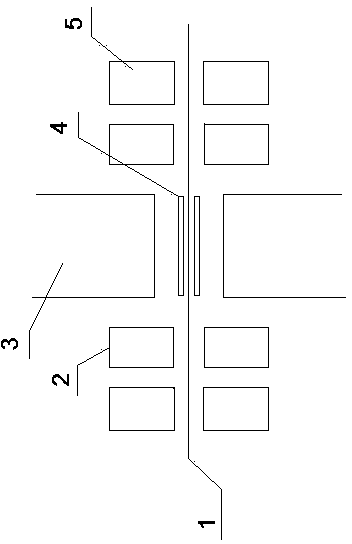

[0013] A lithium battery tab hot-press forming method, comprising an intermediate hot-press mechanism for hot-press bonding the tab strip 4 and the metal strip 1, and the intermediate hot-press mechanism is provided with two upper and lower hot-press heads 3 that move synchronously in opposite directions , two sets of left and right metal belt heating mechanisms are respectively provided on both sides of the above-mentioned pressure heat sealing head, and each group of metal belt heating mechanisms is equipped with two heating heads 2 that move synchronously and oppositely. The working temperature of the heat pressure sealing head Greater than or equal to the softening point temperature of the tab rubber strip but less than the melting point temperature of the tab strip; the working temperature of the heating head is greater than the melting point temperature of the tab strip. After the metal strip heating mechanism starts to heat the metal strip, the intermediate heat After th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com