High-resolution OLED device and masking plate for manufacturing same

A high-resolution and device technology, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems that it is difficult to make high-resolution OLED panels, and achieve improved aperture ratio, clear display, The effect of reducing the requirements of the process technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following embodiments of the present invention are designed according to the principles of the present invention. The protection scope of the technical solution of the present invention includes but is not limited to the scope of the following specific embodiments. The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

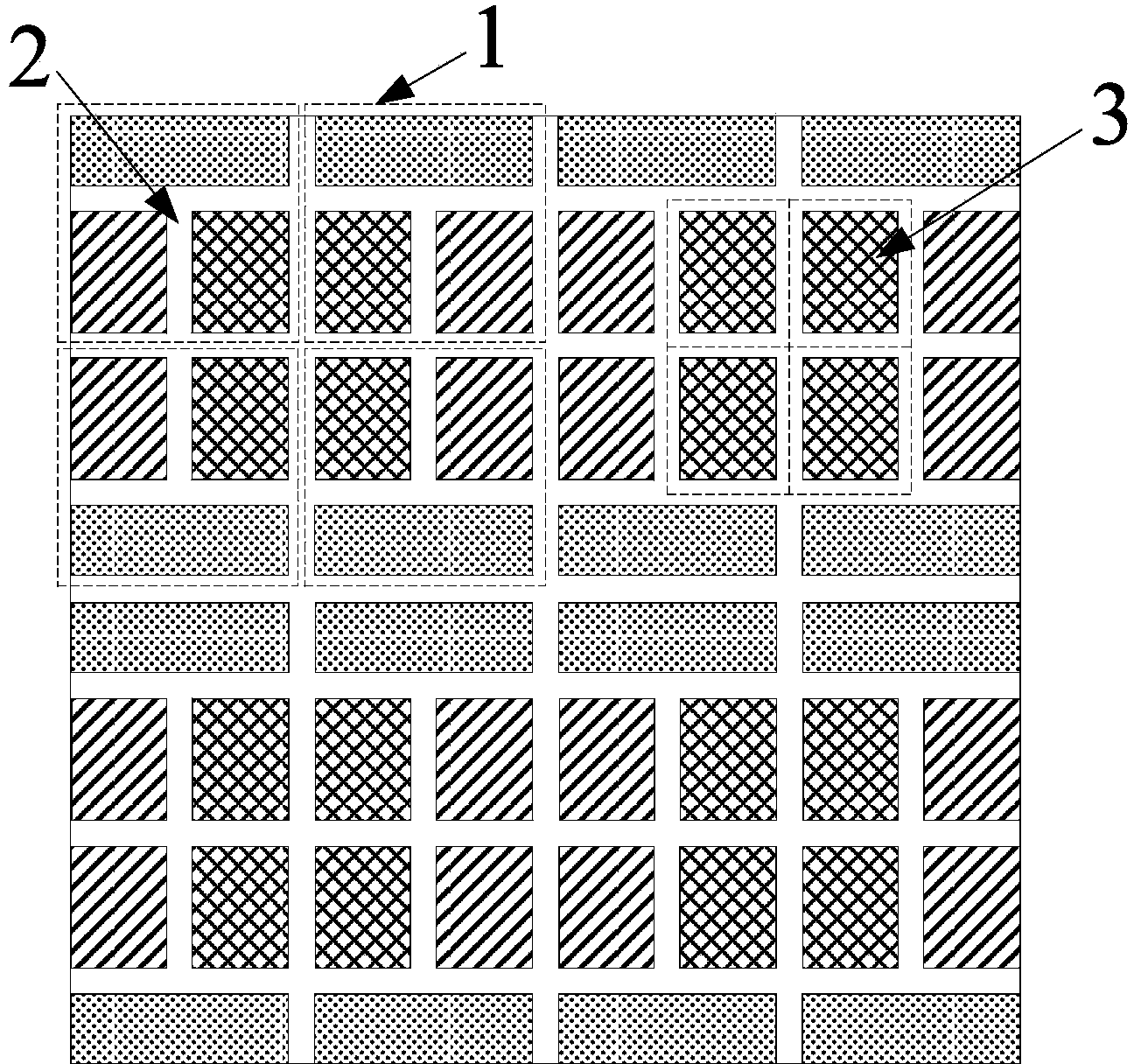

[0023] Such as figure 2 As shown, a high-resolution OLED device of this embodiment includes pixel groups 1 arranged in a matrix, a single pixel group 1 includes four pixels 2, and a single pixel 2 includes red, green, and blue sub-pixels; The three-color sub-pixels of red, green, and blue are arranged in a pixel in a square shape, and the red, green, and blue three-color sub-pixels of adjacent pixels in the pixel group are symmetrical about the common edge of the pixel.

[0024] The four pixels 2 in the pixel group 1 are arranged in a square shape, and the four pixels 2 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com