Method for optimizing design parameters of induction cavity of micro-channel acceleration meter

A technology of accelerometer and design parameters, which is applied in the field of sensors, can solve the problems of time-consuming and labor-intensive, and increase R&D costs, and achieve the effects of reducing R&D costs, improving R&D efficiency, and speeding up R&D speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

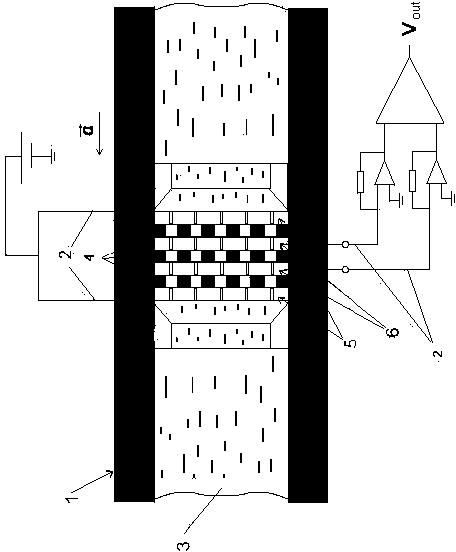

Image

Examples

Embodiment

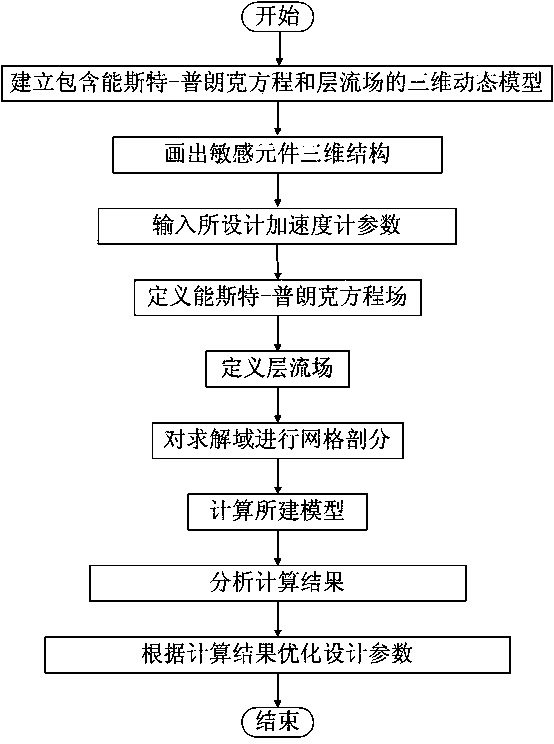

[0098] According to the above process of modeling, input the corresponding parameters during the modeling process, the built model is as follows image 3 shown. The mesh division diagram of the model is as follows Figure 4 As shown, the calculation result of the concentration of a filling variable in the model is as follows Figure 5 As shown, the calculation result of the current density of the z component is as follows Figure 5 As shown, the current density calculation results of the x and y components are not shown here. Then the calculation results are analyzed, and finally the design parameters are optimized according to the calculation results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com