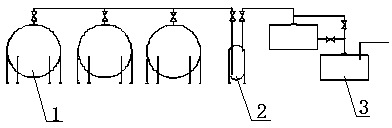

Negative-pressure and inert gas displacement method for large-scale spherical tank

A technology of inert gas and replacement method, which is applied in the direction of container discharge, gas/liquid distribution and storage, container filling method, etc. It can solve the problems of incomplete pipeline replacement, large consumption of inert gas, and long replacement time, etc., to achieve The effect of shortening replacement time, maximizing benefits, and low replacement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] According to the current research and analysis of large-scale spherical tank replacement methods in China, if the replacement of spherical tanks is carried out with inert gas positive pressure replacement method, it will cost a lot and take a long time, and the subsequent water replacement method will have a greater impact on materials. Based on many years of work experience, a negative pressure plus inert gas replacement method has been developed. According to the material of the spherical tank, the tank capacity and the thickness of the tank wall, the capacity of the spherical tank to withstand external pressure is obtained, and then the gas displacement and negative pressure limit of the equipped vacuum pump set are calculated according to the capacity of the spherical tank (the first-level negative pressure can be used or the second-level negative pressure can be used) level negative pressure). The replacement process includes the following steps:

[0014] a. Vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com