Composite material shear key for steel-concrete combined structure

A combined structure and composite material technology, applied to bridge materials, bridge parts, bridges, etc., can solve the problems of discontinuous stress on studs, uneven stress on studs, and inability to fully utilize the shear resistance of studs. Achieve the effect of preventing peeling and enhancing shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

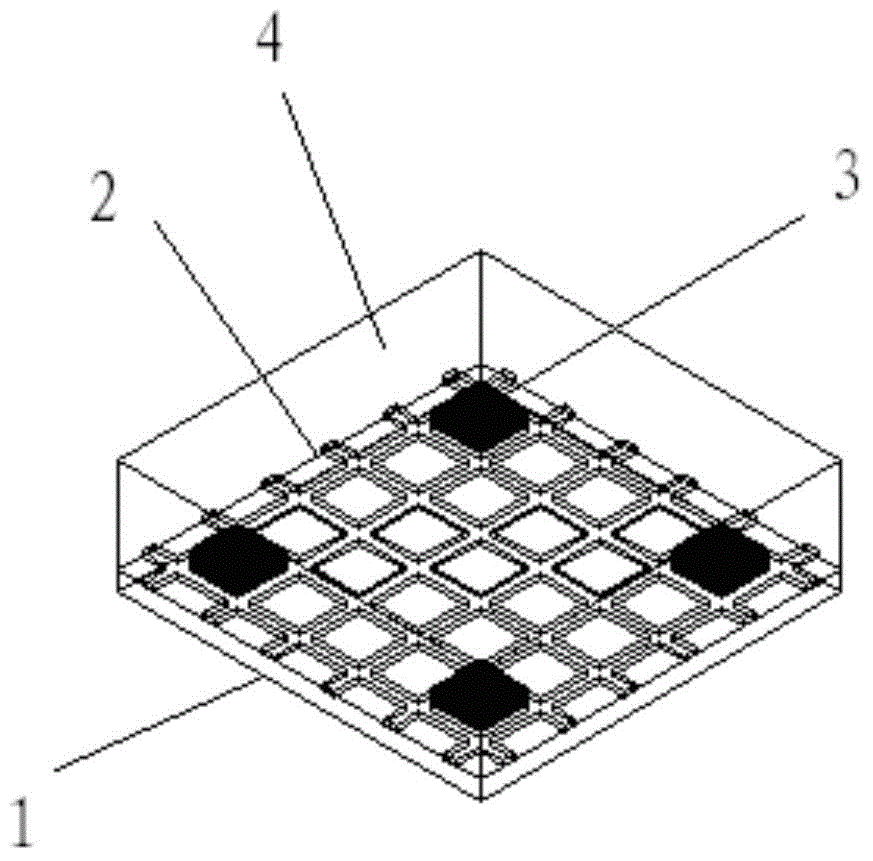

[0033] Such as figure 1 , 4 , 5, 6, and 13 show that the present invention is a composite material shear key for a steel-concrete composite structure. The steel plate 1 is an orthotropic steel plate, the fiber grid 2 is a single-layer or multi-layer carbon fiber grid, the grid rib is 10 mm, the side length of the mesh is 90 mm, and the thickness is 5 mm. The steel block 3 is arranged along the edge in the fiber grid 2, and the steel block 3 is cemented or mechanically connected to the steel plate 1 in the form of no flange. The size of the steel block and the mesh is consistent, and the concrete is steel fiber concrete.

Embodiment 2

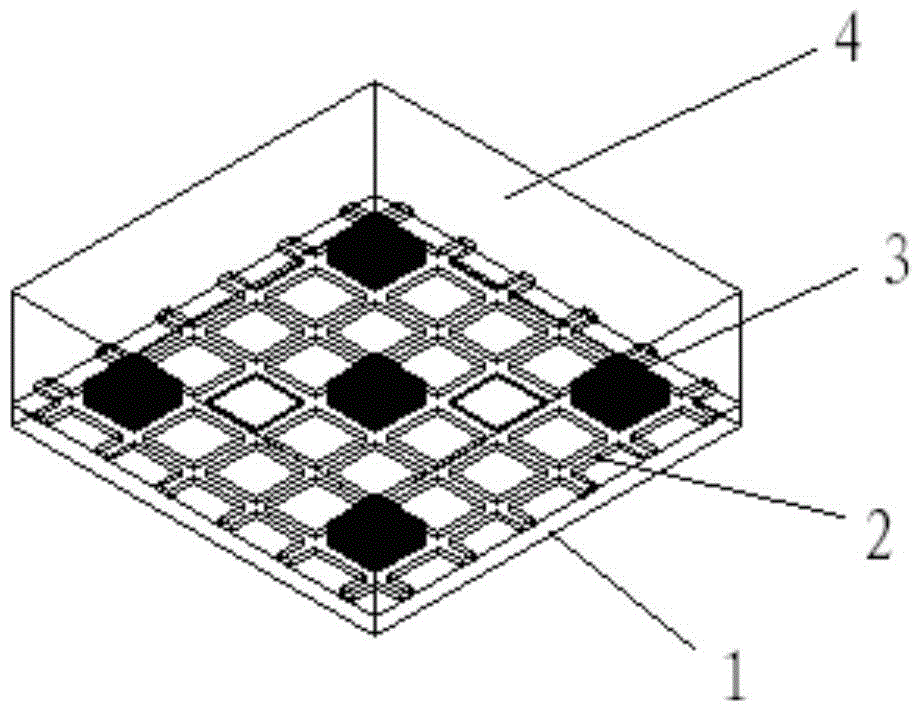

[0035] Such as figure 2 , 7 As shown in -10, the present invention is a composite material shear key for a steel-concrete composite structure, which is composed of a steel plate 1, a fiber grid 2, a steel block 3 and concrete 4. The steel plate 1 is an orthotropic steel plate, the fiber grid 2 is a single-layer carbon fiber grid, and the fiber grid 2 adopts a grid rib of 10mm, a mesh side length of 90mm, and a thickness of 5mm. The steel block 3 is arranged in a plum blossom shape in the fiber grid 3, the steel block 3 is cemented on the steel plate 1, the diameter of the nut is 100mm, and the concrete 4 is made of reactive powder concrete. The steel block 3 is 5 steel blocks with square flanges on both sides, 6 steel blocks with wedge-shaped flanges on both sides, 5 steel blocks with square flanges on four sides or 6 steel blocks with wedge-shaped flanges on four sides.

Embodiment 3

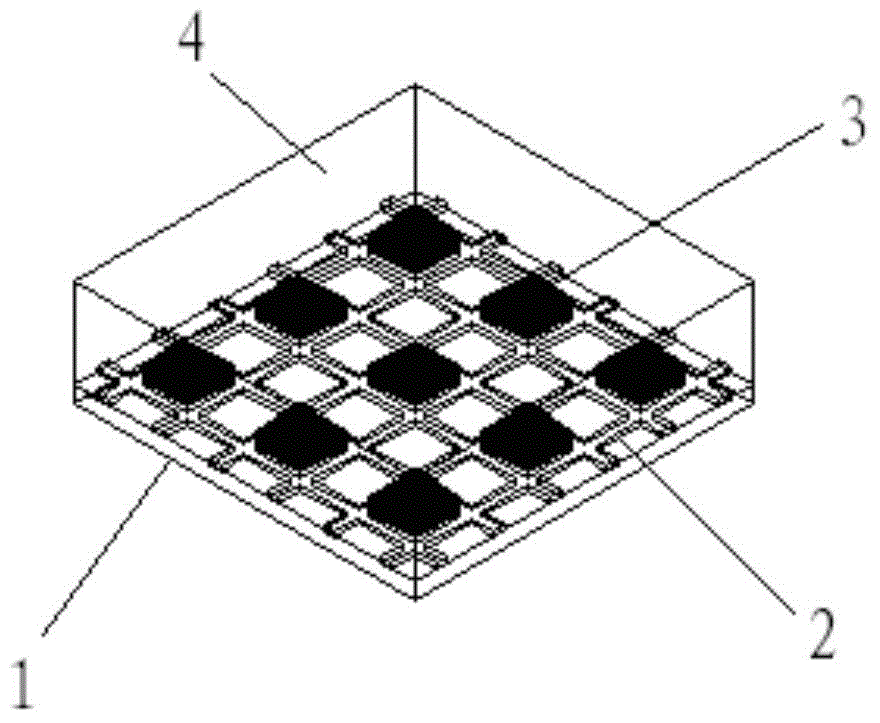

[0037] Such as image 3 , 11 , Shown in 12, 14-18, the present invention is a composite material shear key for a steel-concrete composite structure, the component is made up of a steel plate 1, a fiber grid 2, a steel block 3 and concrete 4. The steel plate 1 is an orthotropic steel plate, the fiber grid 2 is a single-layer carbon fiber grid, and the grids are cemented with connecting rods, and the fiber grid rib 2 adopts grid ribs of 15mm, mesh side length of 135mm, and thickness of 6mm. The steel blocks 3 are evenly arranged in the fiber grid 2, the steel blocks 3 are mechanically connected to the steel plate 1, the studs are welded on the steel plate 1, the steel blocks 3 are set on the pegs through the reserved holes, and a diameter larger than The nut with the reserved hole is fixed. The steel block 3 is 5 steel blocks with square flanges on both sides, 6 steel blocks with wedge-shaped flanges on both sides, 5 steel blocks with square flanges on four sides or 6 steel bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com