Composite printing paste and preparation method thereof

A technology of printing paste and weight, applied in dyeing, textile and papermaking, etc., can solve the problems of poor hand feel, unclean and difficult to remove paste, etc., and achieve the effect of improving hand feeling, saving process, and easy to remove paste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Aliphatic amine polyoxyethylene ether 1815 is pre-processed into a solid material through atomization drying equipment (purchased from the manufacturer?). Then mix 900g of CMS, 50g of sodium alginate, 10g of amylase NS, 15g of dipitan and 25g of atomized and dried 1815, and stir evenly to obtain a composite printing paste. Wherein, the degree of substitution of CMS is 1.0, the viscosity of 1% aqueous solution is 410 mPa.s; the molecular weight of diyout gum is 285 Daltons. The application properties of the composite printing paste are shown in Table 1.

Embodiment 2

[0068] Aliphatic amine polyoxyethylene ether 1810 is pre-processed into solid material through atomization drying equipment. Then mix 850g of CMC, 70g of sodium alginate, 30g of amylase NS, 10g of dipitan and 40g of atomized and dried 1810, and stir evenly to obtain a composite printing paste. Wherein, the degree of substitution of CMC is 1.5, the viscosity of 1% aqueous solution is 450 mPa.s; the molecular weight of Diyou gum is 400 Daltons. The application properties of the composite printing paste are shown in Table 1.

Embodiment 3

[0070] Aliphatic amine polyoxyethylene ether 1210 is pre-processed into solid material through atomization drying equipment. Then mix 650g of CMS, 300g of CMC, 24g of amylase NS, 6g of dipitan and 20g of atomized and dried 1210, and stir evenly to obtain the composite printing paste. Among them, the degree of substitution of CMS is 1.1, and the viscosity of 1% aqueous solution is 330 mPa.s; the degree of substitution of CMC is 1.8, and the viscosity of 1% aqueous solution is 350 mPa.s; the molecular weight of dipitan gum is 580 Daltons. The application properties of the composite printing paste are shown in Table 1.

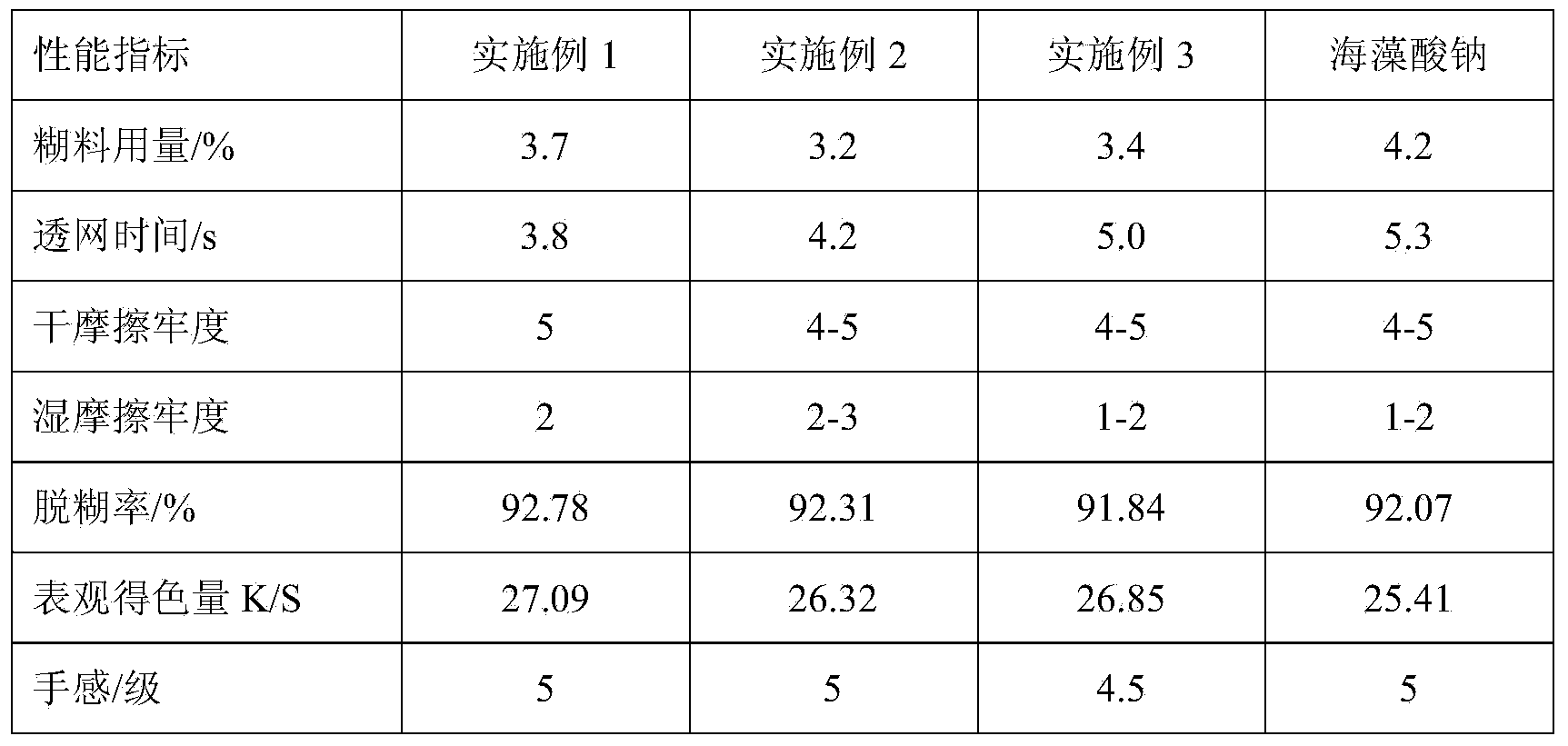

[0071] Table 1 Application performance comparison between compound paste and sodium alginate

[0072]

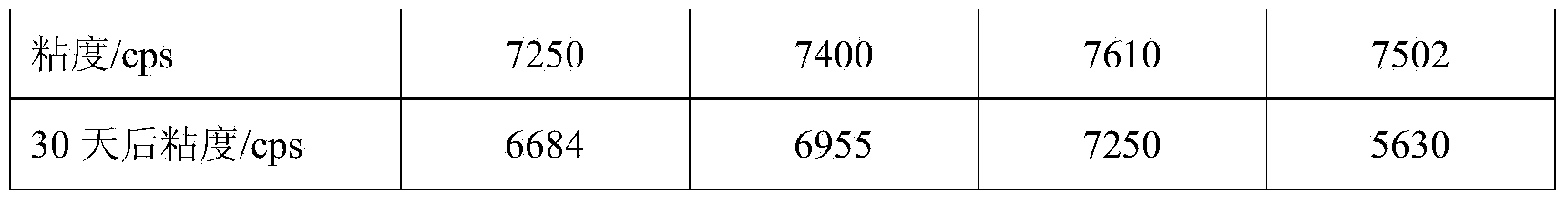

[0073]

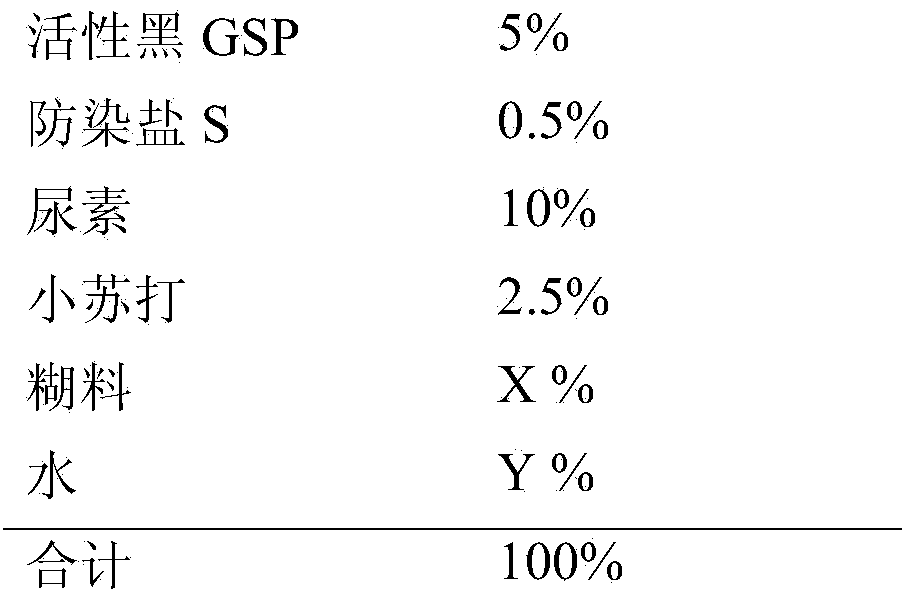

[0074] Table 2: the formula of embodiment 1-4

[0075]

[0076] From the application results in Table 1, it can be clearly seen that the composite printing paste of the present invention has various performance indicators equivalent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com