Compound leak preventive for oil-based drilling fluid

An oil-based drilling fluid and anti-leakage technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve problems such as the compatibility of anti-leakage agents, and achieve permeability loss, good adaptability, and compatibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

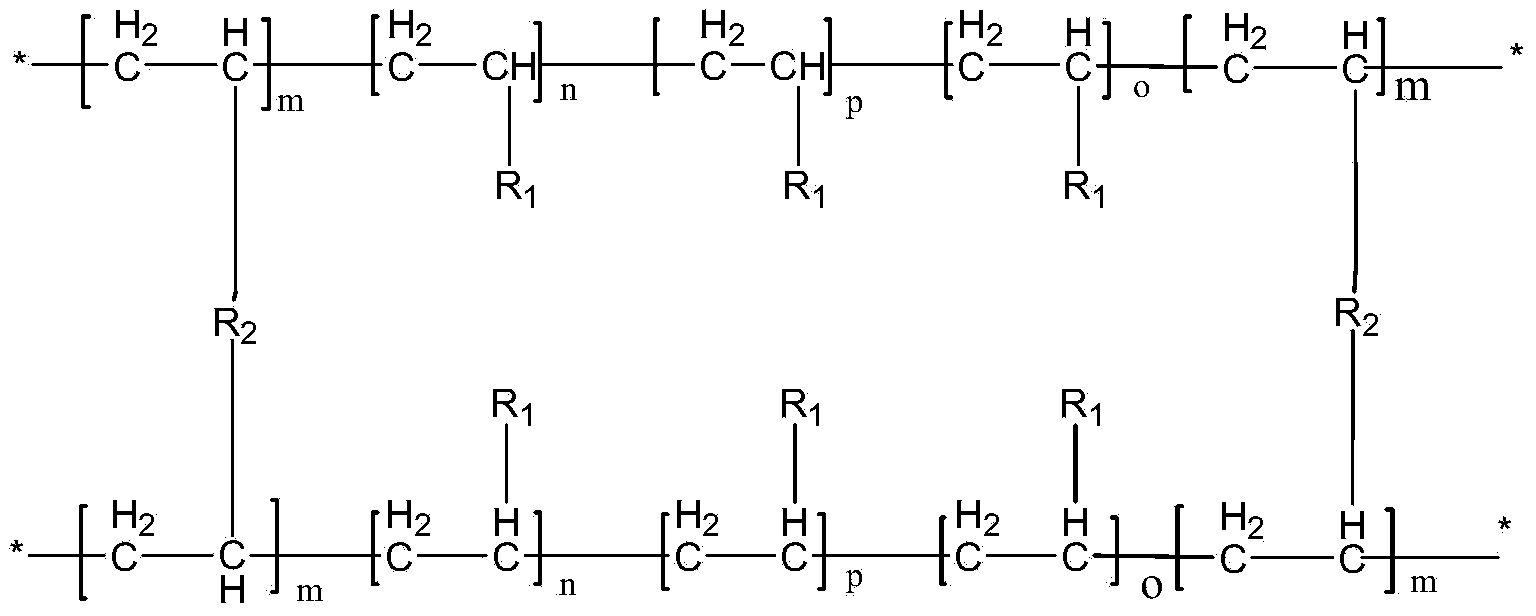

[0018] Embodiment 1: 40 parts of spherical gel products, 30 parts of superfine calcium carbonate of 10um particle diameter, 20 parts of asbestos fluff powder of length 380um, 10 parts of expanded graphite of particle diameter 75um, put in mixing equipment and carry out uniform mixing and get final product The composite anti-leakage agent for oil-based drilling fluid, wherein the spherical gel structural formula used is:

[0019]

Embodiment 2

[0020] Embodiment 2: 45 parts of spherical gel products, 21 parts of superfine calcium carbonate of 18um particle diameter, 9 parts of superfine calcium carbonate of 10um particle diameter, 15 parts of sepiolite wool of 75~380um length, 15 parts of expanded graphite of 45um Put it in the mixing equipment for uniform mixing to get the composite anti-leakage agent for oil-based drilling fluid, wherein the spherical gel structural formula used is:

[0021]

Embodiment 3

[0022] Embodiment 3: 50 parts of spherical gel products, a particle diameter of 12 parts of 18um superfine calcium carbonate, a particle diameter of 5 parts of 10um superfine calcium carbonate, a particle diameter of 3 parts of 5um superfine calcium carbonate, and a length of 180um 20 parts of asbestos velvet powder, 5 parts of expanded graphite with a particle size of 75um, and 5 parts of expanded graphite with a particle size of 45um are placed in a mixing device and mixed uniformly to obtain the composite anti-leakage agent for oil-based drilling fluid. The structural formula of spherical gel is:

[0023]

[0024] Product of the present invention is carried out relevant performance evaluation, and result is as follows:

[0025] (1) Compatibility and ability to improve mud cake

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com