Arc extinction nozzle for high-voltage breaker and preparation method thereof

A high-voltage circuit breaker and arc extinguishing nozzle technology, which is applied in the manufacture of circuit breaker components, circuits, emergency protection devices, etc., can solve the problems of poor arc ablation resistance and low thermal conductivity of the nozzle, and achieve excellent mechanical properties and High temperature resistance, improved operation stability, improved breaking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

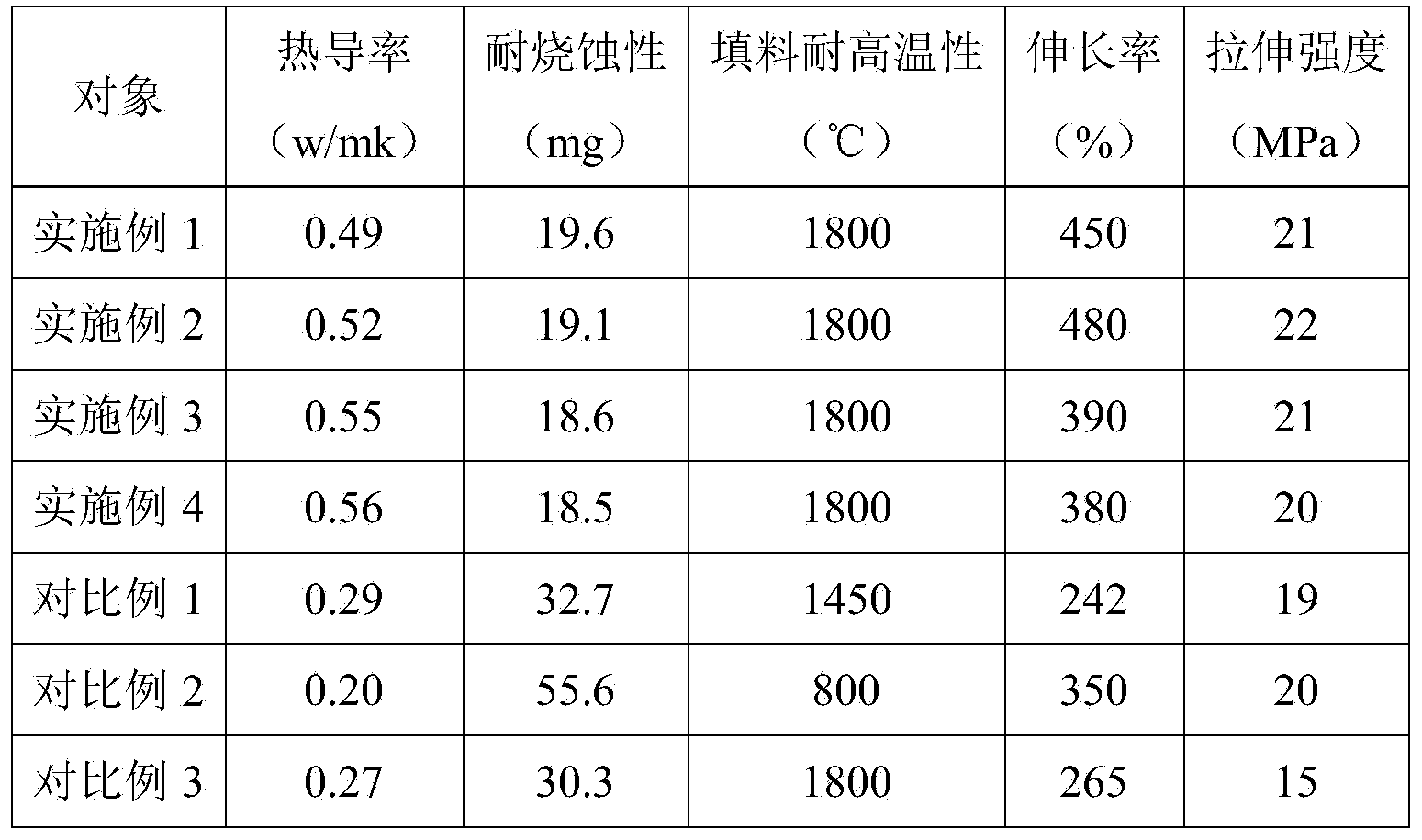

Examples

Embodiment 1

[0017] The arc extinguishing nozzle for a high voltage circuit breaker in this embodiment includes the following components in weight percentage: 5% aluminum nitride, 8% boron nitride, and the balance is polytetrafluoroethylene resin.

[0018] The preparation method of the arc extinguishing nozzle for the high voltage circuit breaker of the present embodiment comprises the following steps:

[0019] 1) Take polytetrafluoroethylene resin powder, disperse and grind it, and mix polytetrafluoroethylene resin powder with a particle size of 45 μm, aluminum nitride powder with a particle size of 2 μm, and nitrided aluminum powder with a particle size of 1 μm according to the formula. After the boron powder is initially mixed, it is placed in a high-speed mixer for final mixing (the rotating speed is 500r / min, and the time is 20min) to obtain a compound;

[0020] 2) adding the mixture obtained in step 1) into a mold for compression molding, the molding pressure is 20MPa, and the mold i...

Embodiment 2

[0023] The arc extinguishing nozzle for a high voltage circuit breaker in this embodiment includes the following components in weight percentage: 10% aluminum nitride, 1% boron nitride, and the balance is polytetrafluoroethylene resin.

[0024] The preparation method of the arc extinguishing nozzle for the high voltage circuit breaker of the present embodiment comprises the following steps:

[0025] 1) Take polytetrafluoroethylene resin powder, disperse and grind it, and mix polytetrafluoroethylene resin powder with a particle size of 80 μm, aluminum nitride powder with a particle size of 8 μm, and nitrided aluminum powder with a particle size of 3 μm according to the formula. After the boron powder is initially mixed, it is placed in a high-speed mixer for final mixing (the rotating speed is 500r / min, and the time is 20min) to obtain a compound;

[0026] 2) adding the mixture obtained in step 1) into a mold for compression molding, the molding pressure is 25MPa, and the mold ...

Embodiment 3

[0029] The arc extinguishing nozzle for the high voltage circuit breaker of this embodiment includes the following components in weight percentage: 7% of aluminum nitride, 10% of boron nitride, and the balance is polytetrafluoroethylene resin.

[0030] The preparation method of the arc extinguishing nozzle for the high voltage circuit breaker of the present embodiment comprises the following steps:

[0031] 1) Take polytetrafluoroethylene resin powder, disperse and grind it, and mix polytetrafluoroethylene resin powder with a particle size of 60 μm, aluminum nitride powder with a particle size of 5 μm, and nitrided aluminum powder with a particle size of 2 μm according to the formula. After the boron powder is initially mixed, it is placed in a high-speed mixer for final mixing (the rotating speed is 500r / min, and the time is 20min) to obtain a compound;

[0032] 2) adding the mixture obtained in step 1) into a mold for compression molding, the molding pressure is 30MPa, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com