Compost preparation method for reducing emission of greenhouse gases in kitchen garbage compost

A kitchen waste and composting technology, which is applied in the field of environmental pollution control, can solve the problems of secondary pollution of the environment, reduce the value of composting products, etc., and achieve the effects of reducing emissions, large specific surface area, and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1, the preparation of decomposed compost

[0033] The kitchen waste used in the following experiments was manually crushed to a particle size of 2-8 cm after pre-treatment, and the corn stalks were air-dried and mechanically crushed to 1-5 cm after pre-treatment.

[0034] Preparation of raw materials for the preparation of decomposed compost:

[0035] The raw material of decomposed compost is mixed with kitchen waste and corn stalks at a mass ratio of 17:3 on a wet basis.

[0036] Decomposed compost is fermented according to the following steps:

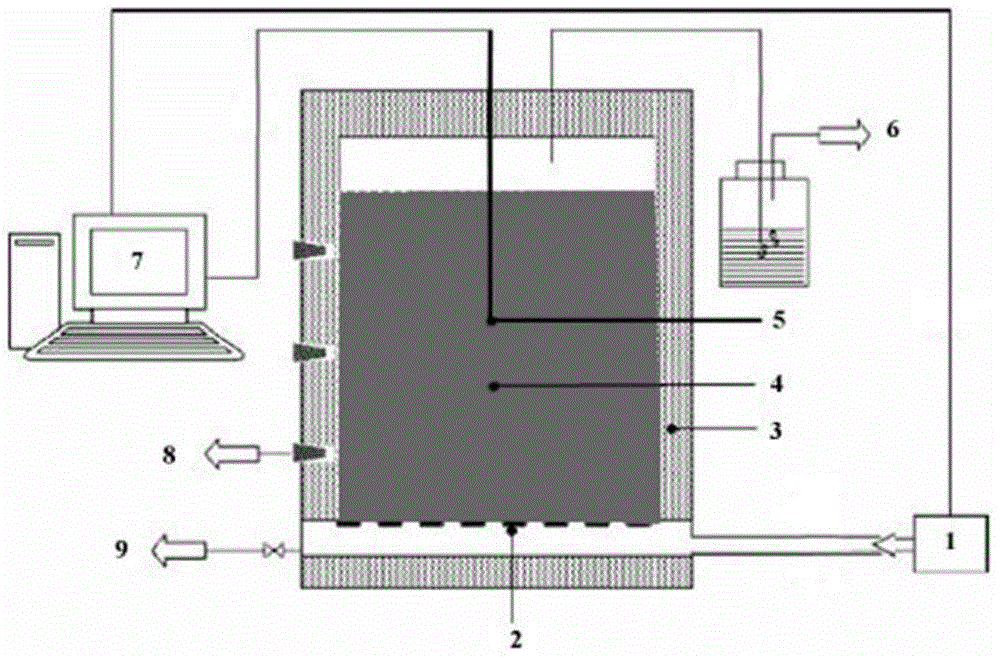

[0037] Composting is carried out in a 60L forced-air fermentation device, the structure of which is as follows: figure 1 As shown, the marks in the figure are as follows: 1 air pump, 2 sieve plate, 3 heat insulation layer, 4 compost raw material, 5 temperature sensor, 6 gas sample collection port, 7 automatic control system, 8 solid sample collection port, 9 leachate collection mouth. A total of 35 days of compo...

Embodiment 2

[0043] Example 2, Compost Preparation of Greenhouse Gas in Emission Reduction Kitchen Waste Compost

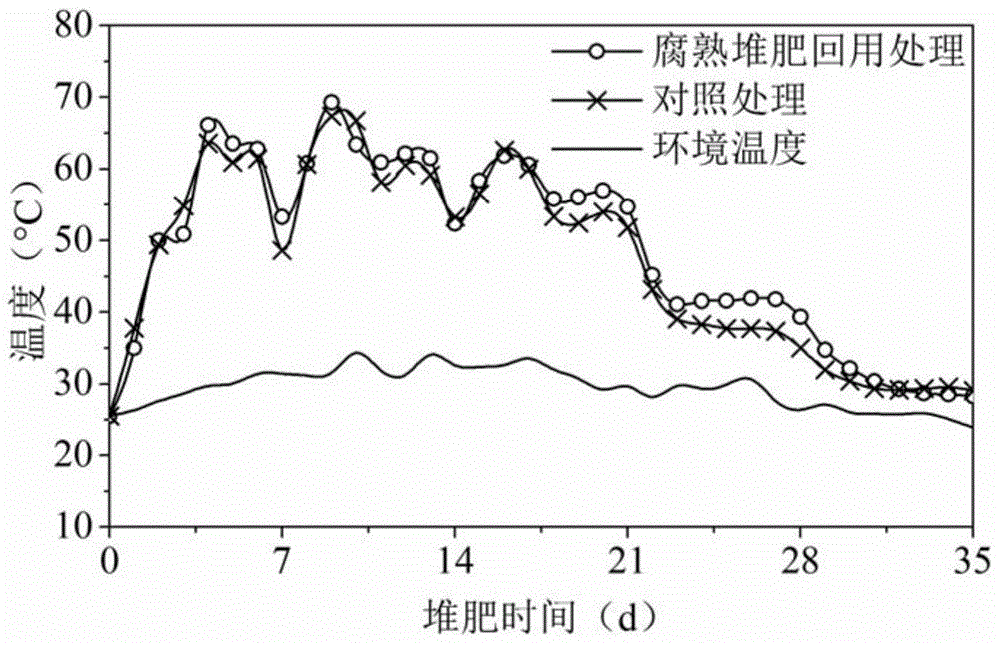

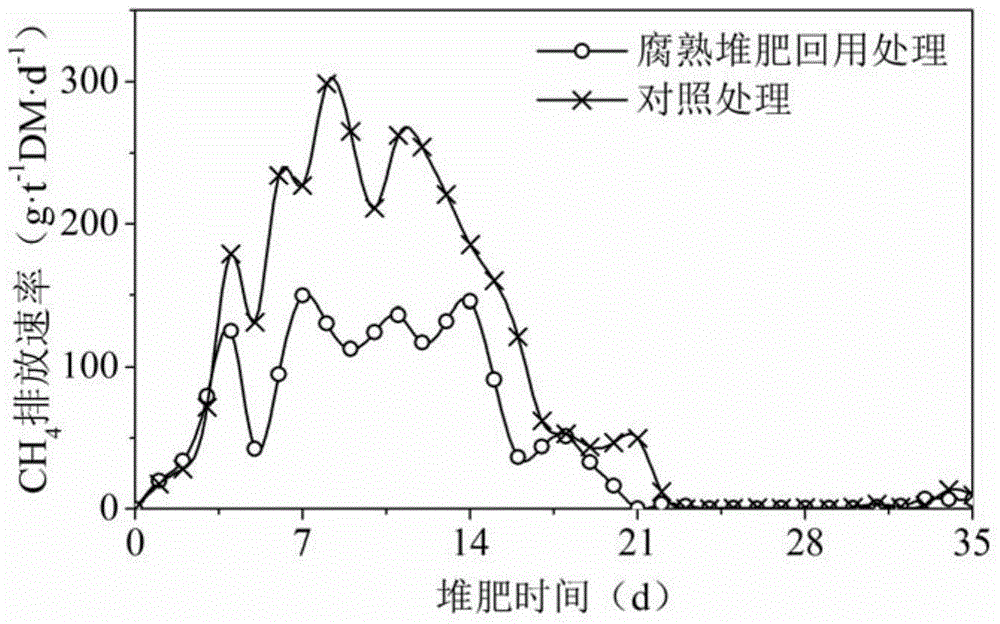

[0044] Two different composting treatments have been designed, the decomposed compost recycling treatment (the composting treatment of the present invention) is to reuse the decomposed compost on the basis of the combined composting of kitchen waste and corn stalks; the control composting treatment is the combined composting of kitchen waste and corn stalks Disposal, did not reuse decomposed compost.

[0045] Preparation of compost raw materials: compost raw materials are mixed according to the mass ratio of kitchen waste and corn stalks to the wet basis of 17:3, and the amount of decomposed compost to be reused is the mass of the wet basis of the above-mentioned kitchen waste and corn stalks mixture The ratio is 1:9, and mix well.

[0046] Compost using device and composting method according to embodiment 1.

[0047] The compost temperature is continuously monitored by a Te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com