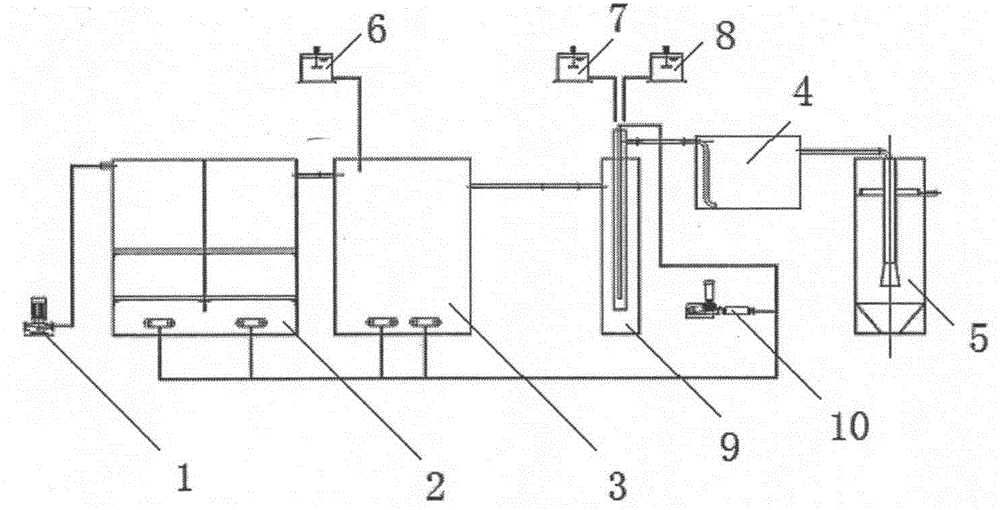

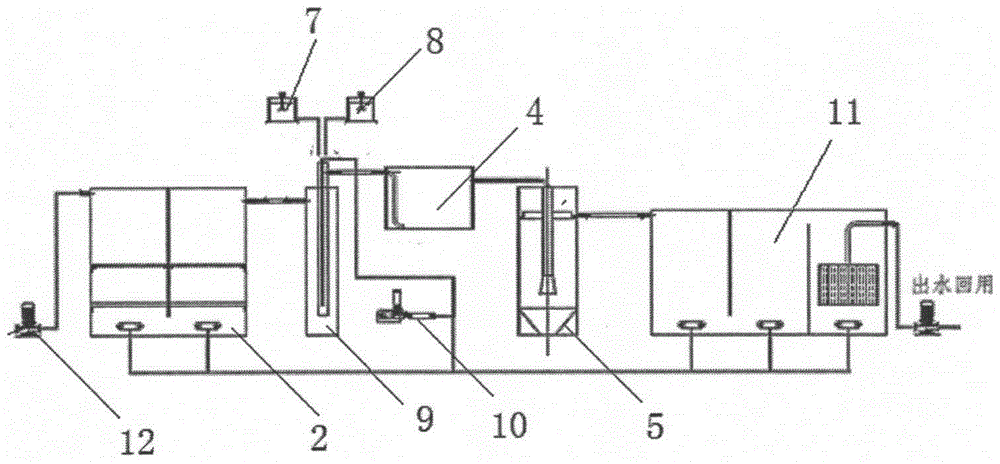

Printing and dyeing wastewater grading treatment method

A technology for the treatment of printing and dyeing wastewater and its quality, which is applied in the textile industry wastewater treatment, water/sewage treatment, biological water/sewage treatment, etc. The total amount of pollutants discharged, the reduction of treatment costs, and the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation of rare earth catalytic oxidizing agent: adopt the waste residue of 3wt% from the rare earth production plant (mainly cerium oxide, accounting for 70% of mixed rare earth oxides, other light rare earth oxides such as lanthanum oxide and neodymium oxide), in the Add 0.1wt% copper shavings to the waste residue, mix the resulting mixture with silicate in a weight ratio of 1:2, slowly add water in stages to make a non-fluid paste, leave it to solidify for 24 hours, and obtain a mixed rare earth catalyst , the radiation dose at 0.1m is less than 0.3μsv; the mixed rare earth catalyst is dispersed into a particle size of 2-10mm, and the mixed rare earth catalyst with a particle size of 2-10mm, coke with a particle size of 3-10mm and particle size of 3 -15mm pig iron is mixed in a weight ratio of 1:5:100 to obtain a mixed rare earth-iron-carbon catalytic oxidant, and the mixed rare earth-iron-carbon catalytic oxidant is packed in a 60-mesh nylon fiber bag to obta...

Embodiment 2

[0027] The preparation of rare earth catalytic oxidant: adopt the waste residue of 5wt% from the rare earth production plant (mainly cerium oxide, accounting for 70% of mixed rare earth oxides, other light rare earth oxides such as lanthanum oxide and neodymium oxide), in the Add 0.1wt% copper shavings to the waste residue, mix the resulting mixture with silicate in a weight ratio of 1:2, slowly add water in stages to make a non-fluid paste, leave it to solidify for 24 hours, and obtain a mixed rare earth catalyst , the radiation dose at 0.1m is less than 0.3μsv; the mixed rare earth catalyst is dispersed into a particle size of 2-10mm, and the mixed rare earth catalyst with a particle size of 2-10mm, coke with a particle size of 3-10mm and particle size of 3 -15mm pig iron is mixed in a weight ratio of 1:5:100 to obtain a mixed rare earth-iron-carbon catalytic oxidant, and the mixed rare earth-iron-carbon catalytic oxidant is packed in a 200-mesh nylon fiber bag to obtain a ra...

Embodiment 3

[0030] The preparation of rare earth catalytic oxidant: adopt the waste residue of 1wt% from rare earth production plant (mainly cerium oxide, accounting for 70% of mixed rare earth oxides, other light rare earth oxides such as lanthanum oxide and neodymium oxide), in the Add 0.1wt% copper shavings to the waste residue, mix the resulting mixture with silicate in a weight ratio of 1:2, slowly add water in stages to make a non-fluid paste, leave it to solidify for 24 hours, and obtain a mixed rare earth catalyst , the radiation dose at 0.1m is less than 0.3μsv; the mixed rare earth catalyst is dispersed into a particle size of 2-10mm, and the mixed rare earth catalyst with a particle size of 2-10mm, coke with a particle size of 3-10mm and particle size of 3 -15mm pig iron is mixed in a weight ratio of 1:5:100 to obtain a mixed rare earth-iron-carbon catalytic oxidant, and the mixed rare earth-iron-carbon catalytic oxidant is packed in a 200-mesh nylon fiber bag to obtain a rare e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com