Method for treating high-concentration organic process wastewater generated in production of 2-chloro-6-fluorobenzaldehyde

A technology of fluorobenzaldehyde and a treatment method, which is applied in the field of organic fine chemical wastewater treatment, can solve the problems of reducing the respiration rate of microorganisms, poor biodegradation performance, and influence on microbial growth, etc. The effect of reducing purification costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

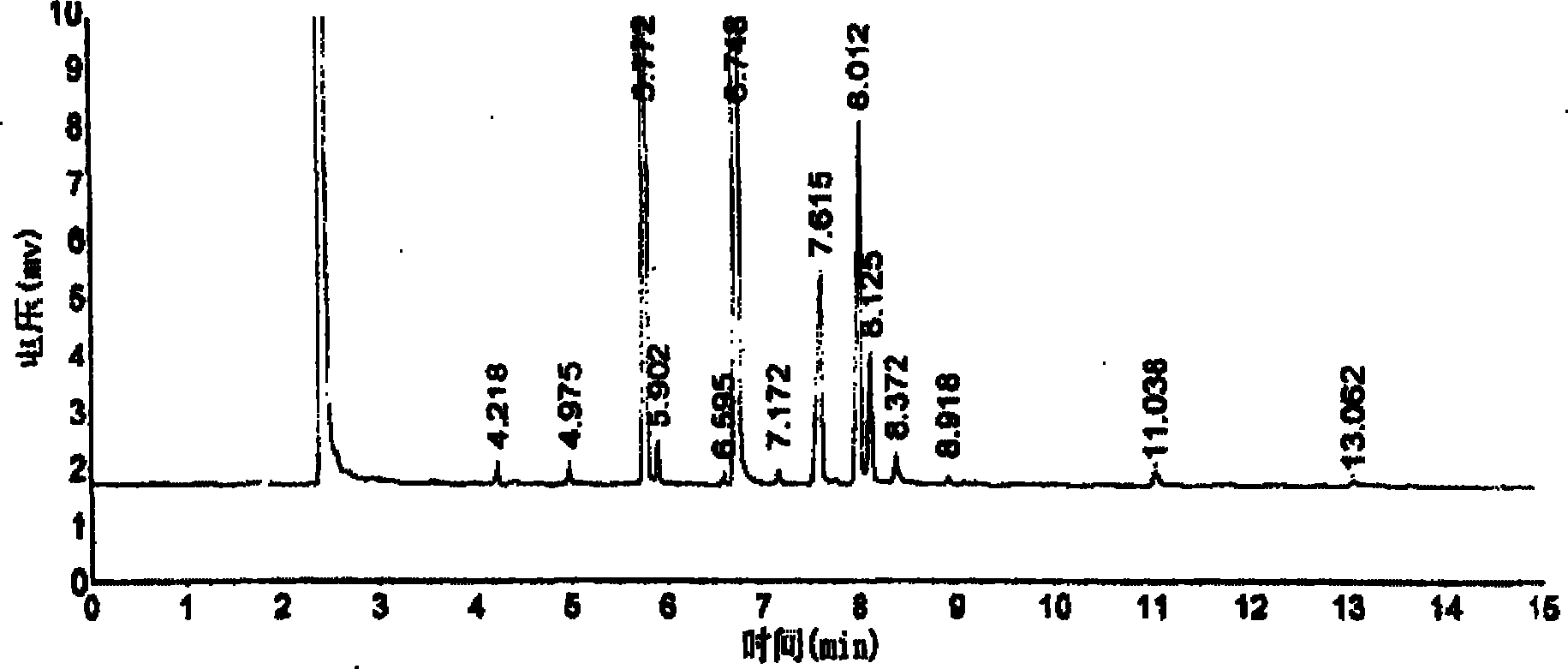

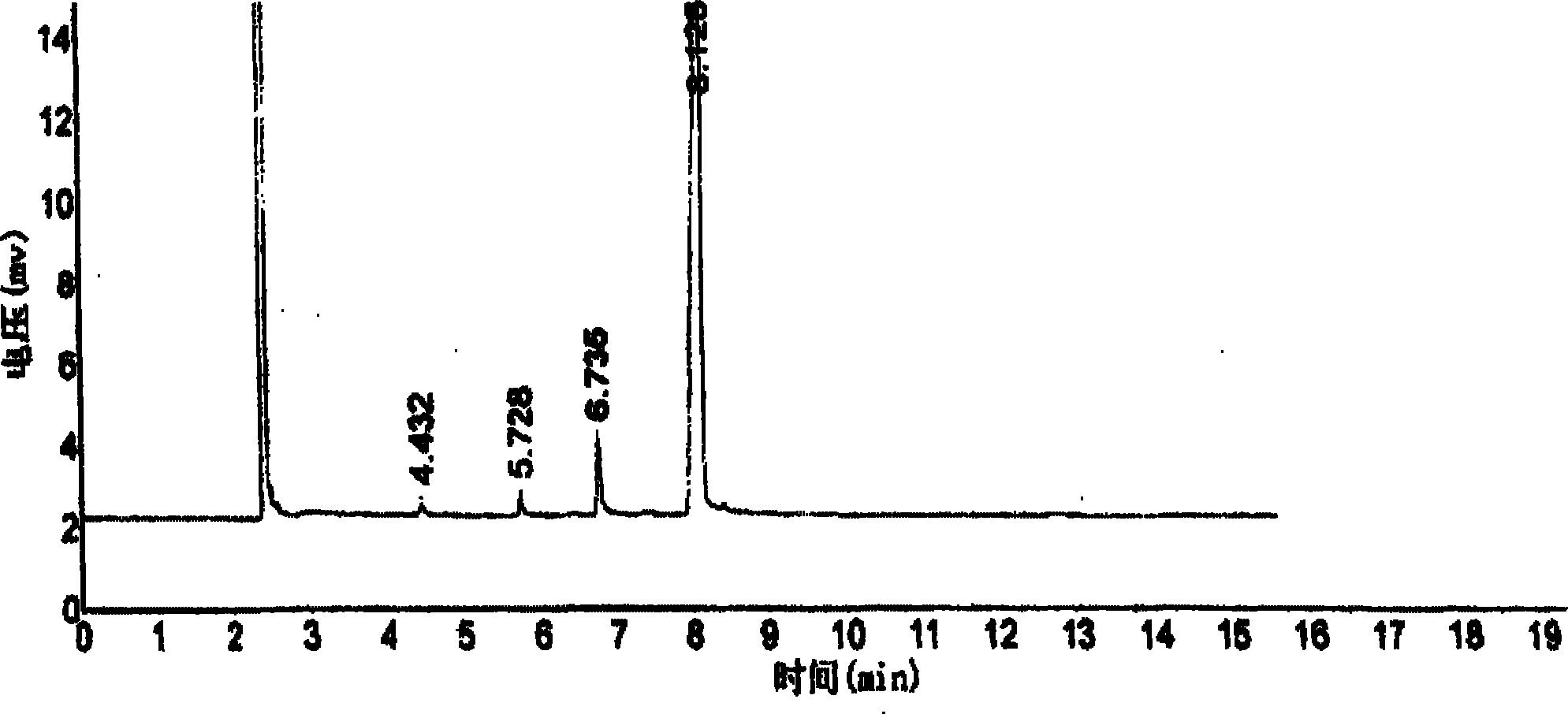

Method used

Image

Examples

Embodiment 1

[0069] Embodiment 1, a kind of processing method of 2-chloro-6-fluorobenzaldehyde high-concentration organic process wastewater (as shown in table 2), carries out following steps successively:

[0070] 1), in 2-chloro-6-fluorobenzaldehyde high-concentration organic process wastewater 15000ml, add quicklime and flocculant (select polyaluminum sulfate for use), the volume mass (ml / g) ratio of process wastewater and quicklime is 1000: 100, The volume-to-mass (ml / g) ratio of the process wastewater to the flocculant is: 1000:5; to remove free fluoride ions in the process wastewater. Then through natural sedimentation or filtration, the wastewater after preliminary treatment is obtained; the suspended matter in the wastewater after preliminary treatment is 20mg / l, F - It is 6mg / l.

[0071] 2), use hydrochloric acid to adjust the pH=5 of the waste water after preliminary treatment;

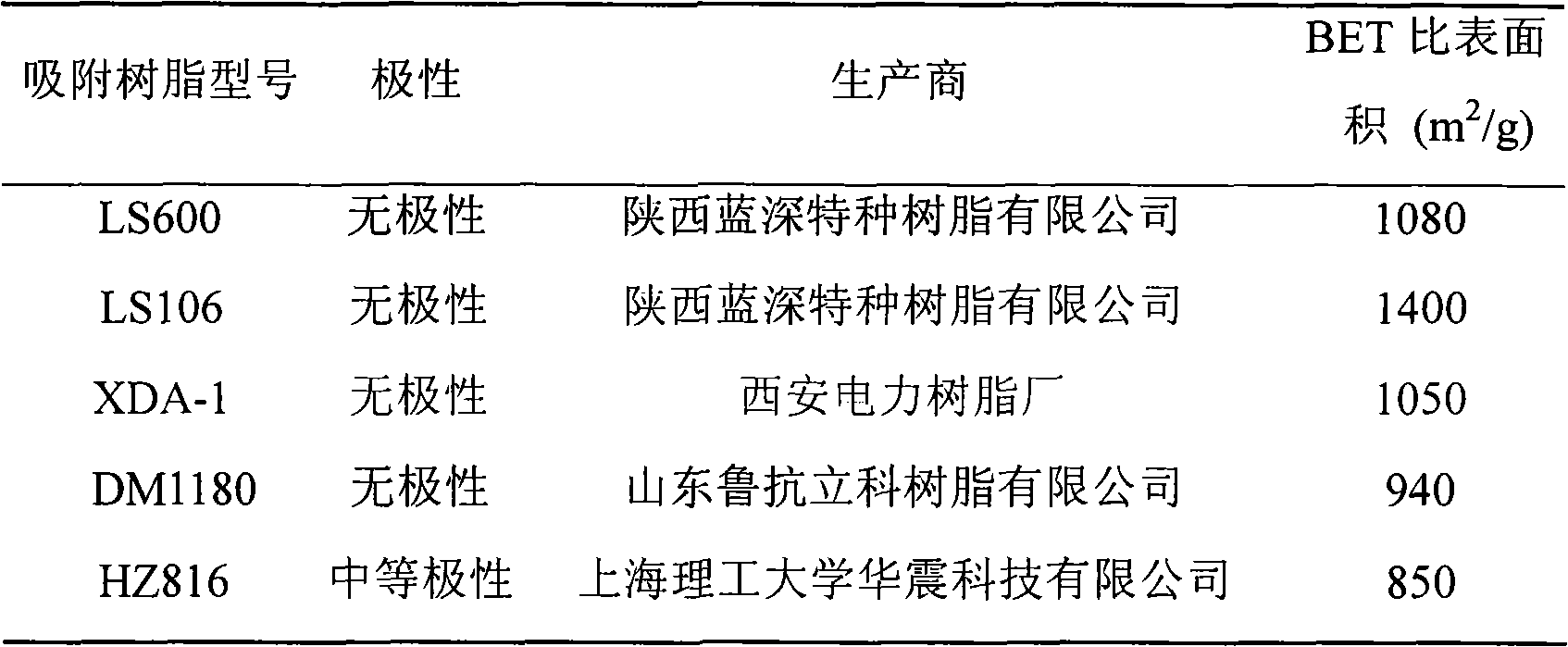

[0072] 3), first carry out the pretreatment of LS600 type resin (for the conventional pretreatment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com