Decorative structure of fiber-reinforced plastic panel and construction process thereof

A technology of decorative structure and construction technology, applied in the direction of engine room flushing device, living cabin, etc., can solve the problems of not being rich enough, not satisfying the ship owner and passengers well, and monotonous interior decoration of the ship, so as to save labor cost and material cost , the appearance is rich in color, and the construction process is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

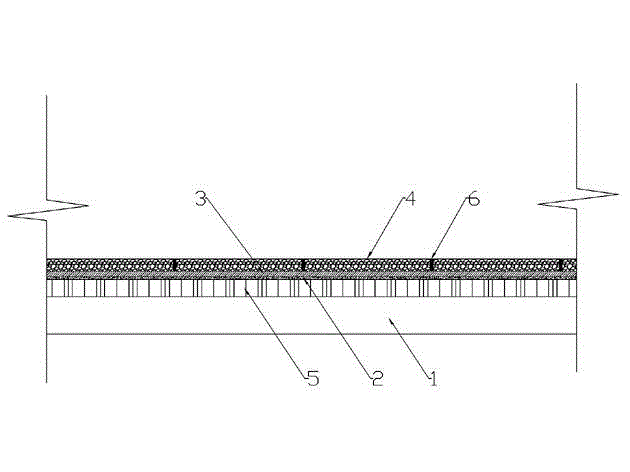

[0022] Such as figure 1 As shown, a decorative structure of a FRP material panel includes a FRP layer 1 , a waterproof coating 2 , an adhesive layer 3 and a decorative layer 4 sequentially arranged from bottom to top.

[0023] In this embodiment, a leveling layer 5 is provided between the FRP layer 1 and the waterproof coating 2, and the leveling layer 5 is an atomic ash leveling layer.

[0024] The decorative layer 4 is formed by splicing one or more of mosaic blocks, ceramic tiles, and wooden blocks. In this embodiment, the decorative layer 4 is formed by splicing mosaic blocks.

[0025] There is a gap 6 with a width below 1.5 mm at the joint of the decoration layer 4 , and in this embodiment, the width of the gap 6 is 1 mm.

[0026] The gap 6 is filled with diluted cement or colored cement. In this embodiment, the gap 6 is filled with colored cement, thereby making the decoration more colorful.

[0027] A construction technique for a decorative structure of a glass-steel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com