Double-flanged PP honeycomb plate luggage case spare cover plate and its production method

A spare tire cover, honeycomb panel technology, applied in spare tire layout, chemical instruments and methods, lamination and other directions, can solve the problem of poor dimensional stability and bonding firmness of PP honeycomb panels, and low production efficiency of artificially sprayed composite fabrics , Unable to realize the problems of double edge pressing of upper and lower fabrics, to achieve the effect of improving efficiency and stability, light weight and reducing the number of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

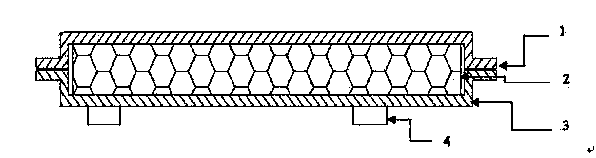

[0017] Example 1, using the PP honeycomb panel as the skeleton layer 2, placing the PP honeycomb panel on the punching tool, and punching it according to the size required by the design with a four-column cutting machine; After the surface layer non-woven fabric 1 and the back layer non-woven fabric 3 of the hot-melt adhesive powder bonded to the PP honeycomb panel are hung separately, the punched PP honeycomb panel is placed in the groove of the lower heating plate, and heated at the heating temperature. Under the conditions of 180°C and a holding time of 50s, close the heating and bonding tool to complete the composite and crimp bonding of the three materials. At this time, the surface layer non-woven fabric 1 and the back layer non-woven fabric 3 are double crimping Composite bonding; the upper and lower heating plates here can be composed of N heating zones, and each heating zone is controlled by a separate temperature control system. Multi-zone heating is easy to control t...

Embodiment 2

[0018] Example 2 is the same as Example 1, the difference is that, when heating the composite pressing, the heating temperature is 130°C, and the holding time is 60s, and the heating and bonding tool is closed to complete the composite and pressing of the three materials. Edge bonding; when cooling and shaping, under the conditions of cooling temperature 15°C and pressure holding time 50s, close the tooling, and open the tooling to take out the product after the set time is reached.

Embodiment 3

[0019] Example 3 is the same as Example 1, the difference is that, when heating the composite pressing, the heating temperature is 230°C, and the holding time is 40s, and the heating and bonding tool is closed to complete the composite and pressing of the three materials. Edge bonding; when cooling and shaping, under the conditions of cooling temperature 25°C and pressure holding time 70s, close the tooling, and open the tooling to take out the product after the set time is reached.

[0020] The spare wheel cover of the suitcase prepared in the above embodiments has the characteristics of beautiful appearance, light weight, no smell, safety and environmental protection, sound insulation and noise reduction, etc., and is an ideal interior decoration product of the suitcase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com