A preparation device for phase-change temperature-regulating plastic-wood laminated composite board

A technology for preparing a device and a composite board, applied in the field of composite materials, can solve the problems of long molding time, low extrusion molding strength and low efficiency of plastic-wood composite board

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

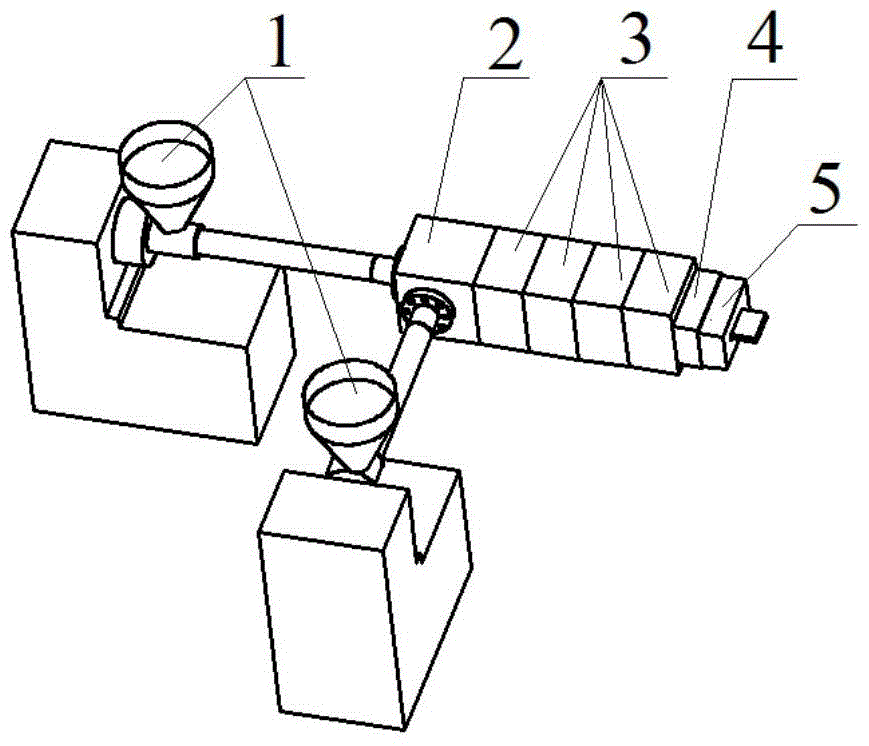

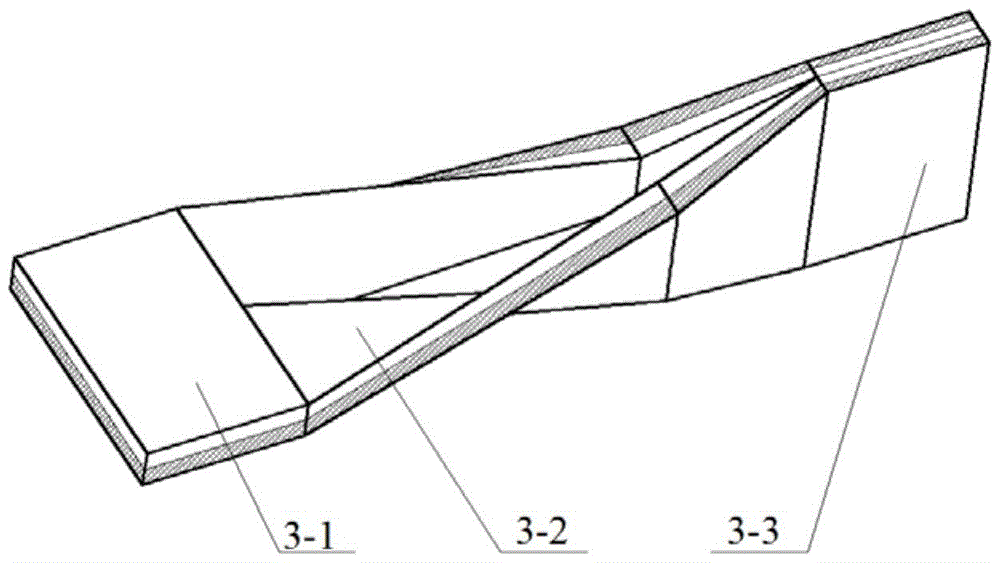

[0019] This example discloses a phase-change temperature-regulating plastic-wood composite board preparation device, the overall shape of which is shown in the attached figure 1 As shown, an extrusion feeding device 1 comprising two or more extruders, a confluence 2, a stacker 3, a boundary forming device 4 and an extrusion forming device 5 are included. The wood-plastic material and the polymer material added with phase-change thermal insulation material are respectively added to two or more extruders to extrude and feed. After passing through the confluence 2, the plastic-wood melt presents an attached image 3 The n-layer melt 3-1 in the middle, the n-layer plastic-wood melt in the confluence 2 is divided into m equal parts along the width direction when leaving the confluence 2, and each equal part is divided into m equal parts in the laminator split flow channel 3-2 When the medium continues to flow forward, it rotates 90 degrees and expands m times, and merges with each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com