Novel injection molding cooling system

A cooling system and a new type of technology, applied in the field of mold injection, can solve the problems of inability to perform cooling alone, waste of water resources, etc., and achieve the effects of avoiding water temperature damage, saving resources, and flexible process adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

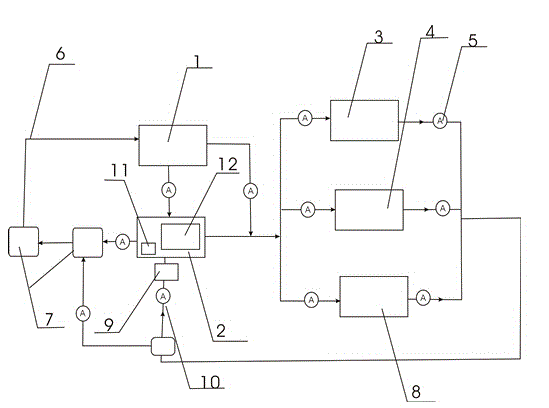

[0012] The invention is a novel cooling system for injection molding, which includes a cold water conveyor 1, a mold temperature controller 2, a mold inlet and return water circulation device, a regulating valve 5, a water delivery pipe 6, a condenser 7, an injection molding machine inlet and return water circulation device 8, and over-temperature protection 9, filter 10, alarm 11, control display screen 12, the mold inlet and return water circulation device includes the movable mold inlet and outlet water circulator 3 and the fixed mold inlet and outlet water circulator 4, the cold water conveyor 1 passes through the water delivery pipe 6 and the mold temperature controller 2 connection, the mold temperature controller 2 is respectively connected with the injection molding machine inlet and return water circulation device 8, the movable mold inlet and return water circulator 3, the fixed mold inlet and return water circulator 4, the injection molding machine inlet and return wa...

Embodiment 2

[0014] When in use, first input the highest warning temperature through the control display screen 12, and then adjust the switching state of the regulating valve 5, when the injection molding machine enters the return water circulation device 8, the movable mold enters the return water circulator 3, and the fixed mold enters the return water circulator 4. When cooling is required, all the regulating valves 5 are opened, and then the water flows into the mold temperature machine 2 through the water delivery pipe 6. Injection molding machine feed and return water circulation device 8, movable mold feed and return water circulator 3, fixed mold feed and return water circulator 4, cool them down and cool them down, and when the cooling is completed, the water returns to the mold temperature controller 2 again from the water outlet and enters the mold temperature controller At 2 o'clock, it must first be filtered through the filter 10 to prevent the impurities in the water delivery...

Embodiment 3

[0016] When it is not necessary to control the temperature for cooling, the water delivery pipe 6 of the mold temperature controller 2 can be closed, and the water inside the cold water conveyor 1 can be directly delivered to the moving mold inlet and return water circulator 3, the fixed mold inlet and return water circulator 4, and the injection molding machine Into the return water circulation device 8 for cooling operation, then the used water is cooled in the condenser 7, and finally enters the cold water conveyor 1 for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com