Production method of spiral plate type cooler cylinder for transformer

A spiral plate type and manufacturing method technology, applied in the direction of transformer/inductor cooling, etc., can solve problems affecting welding quality, deformation on both sides of the steel plate, etc., and achieve the effects of improving production efficiency and product quality, saving welding costs, and small weld seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A method for manufacturing a cylinder of a spiral plate cooler for a transformer, comprising the following steps:

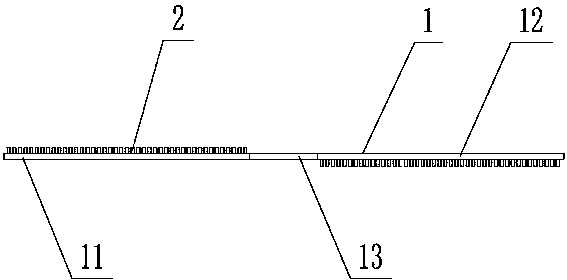

[0031] 1) if figure 1 and figure 2 As shown, prepare a steel plate 1, the steel plate 1 is divided into three parts, the front and rear parts of the steel plate 1 are respectively the front channel area 11 and the rear channel area 12, the middle part is the bending area 13, and the upper side of the steel plate in the front channel area 11 is welded with The spacer column 2, the lower side of the steel plate in the rear channel area 12 is welded with the spacer column 2, and the upper and lower sides of the bending area 13 in the middle are flat steel plates;

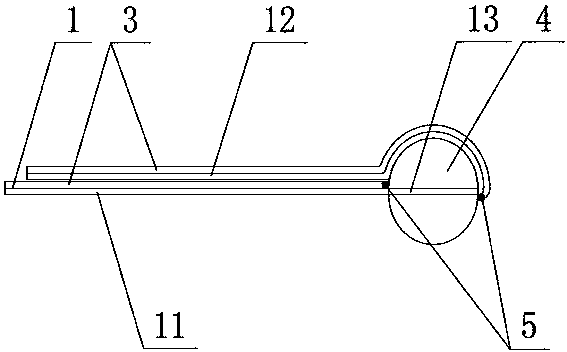

[0032] 2) Four round steel bars 3 are prepared, and the lengths of the four round steel bars 3 are respectively adapted to the lengths of the left and right sides of the steel plates 1 in the front channel area 11 and the rear channel area 12;

[0033] 3) if image 3 and Figure 4 In the proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com