Rapid positioning and clamping system for flexible vehicle body welding line gripper clamp assembly

A technology for positioning, clamping and welding lines, applied in auxiliary devices, vehicle components, manufacturing tools, etc., can solve the problems of increased equipment cost, heavy positioning fixture weight, complex mechanism, etc., to increase positioning accuracy and precision, pressure The effect of effective transmission of tightening force and firm and reliable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

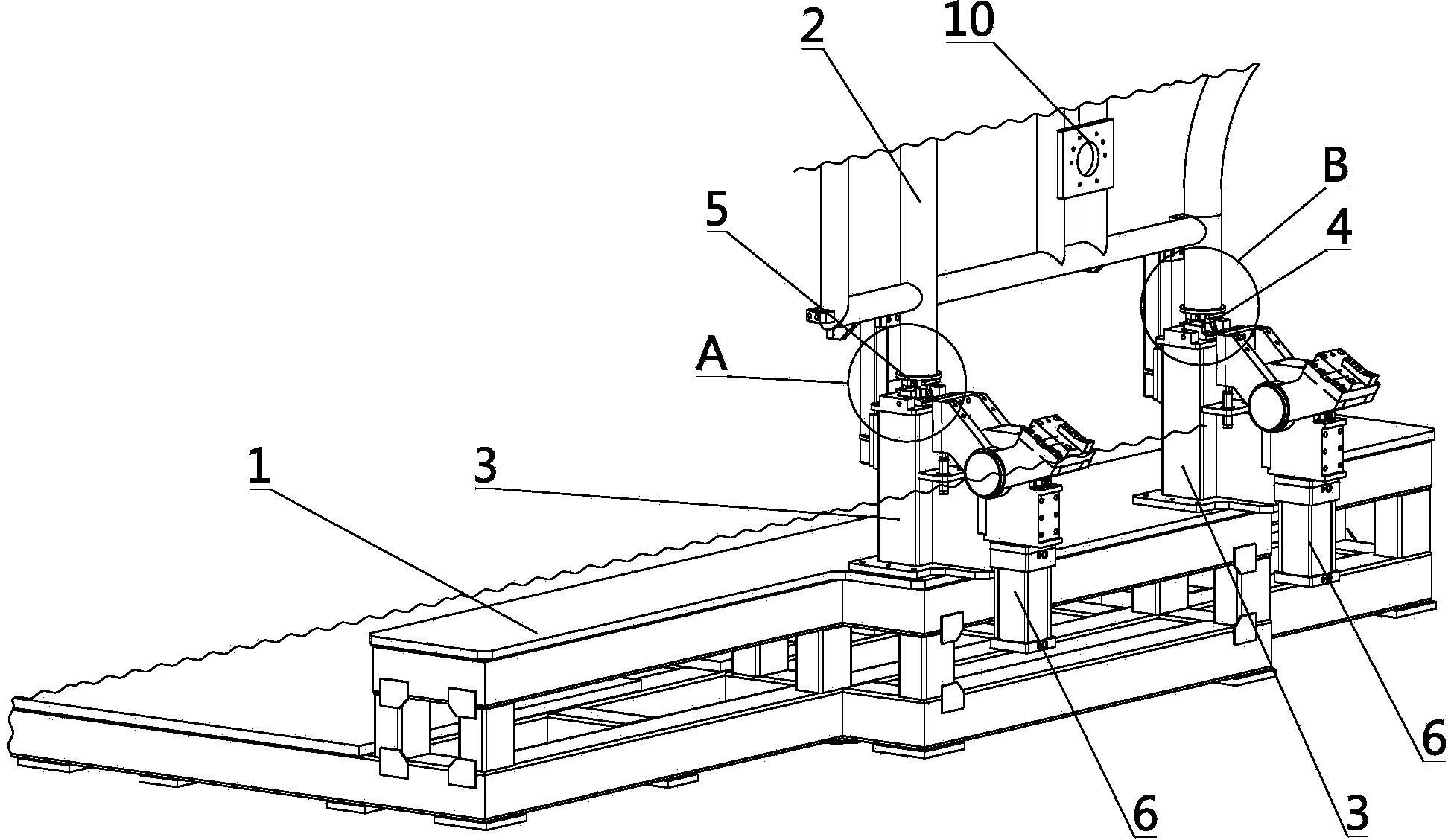

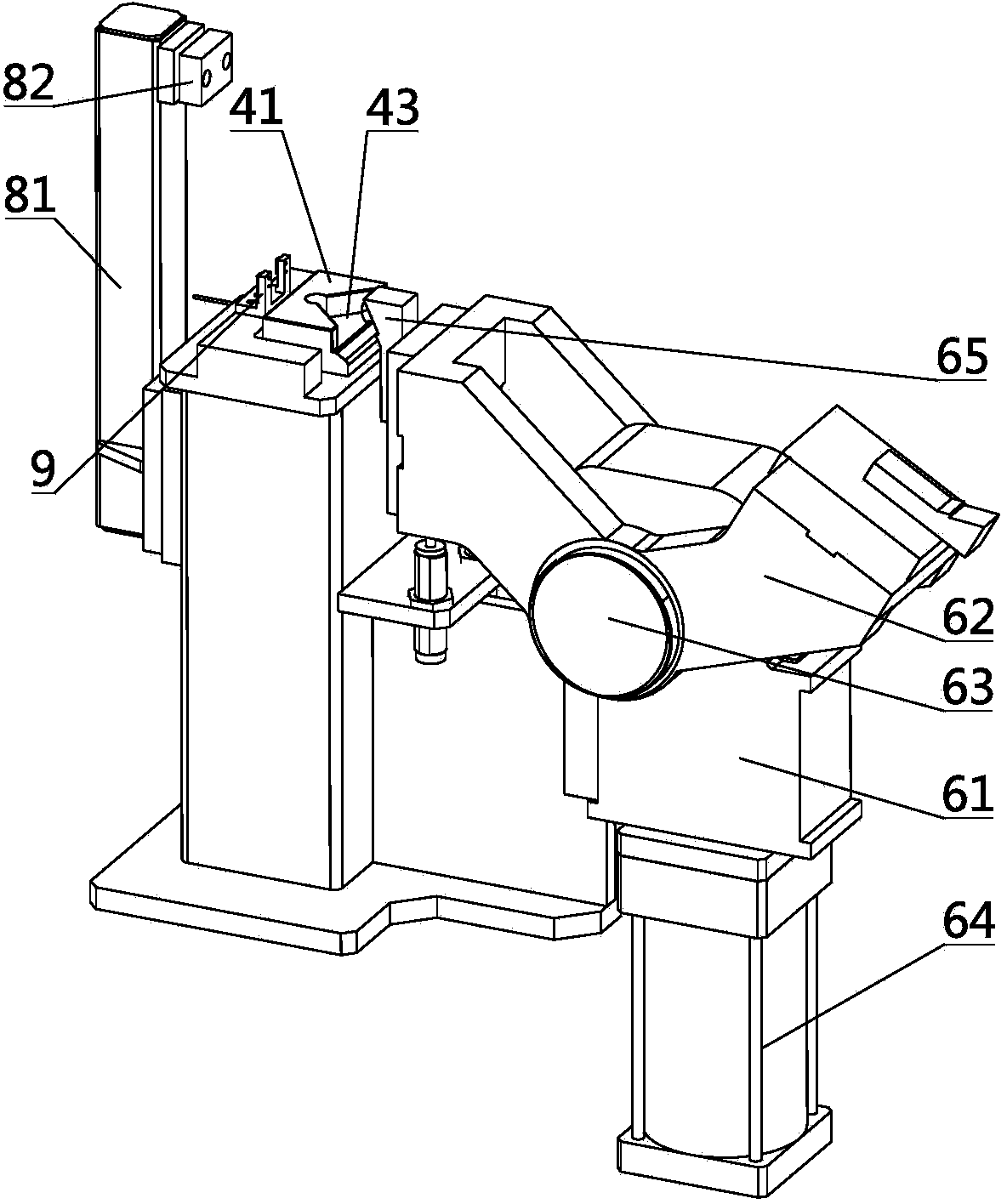

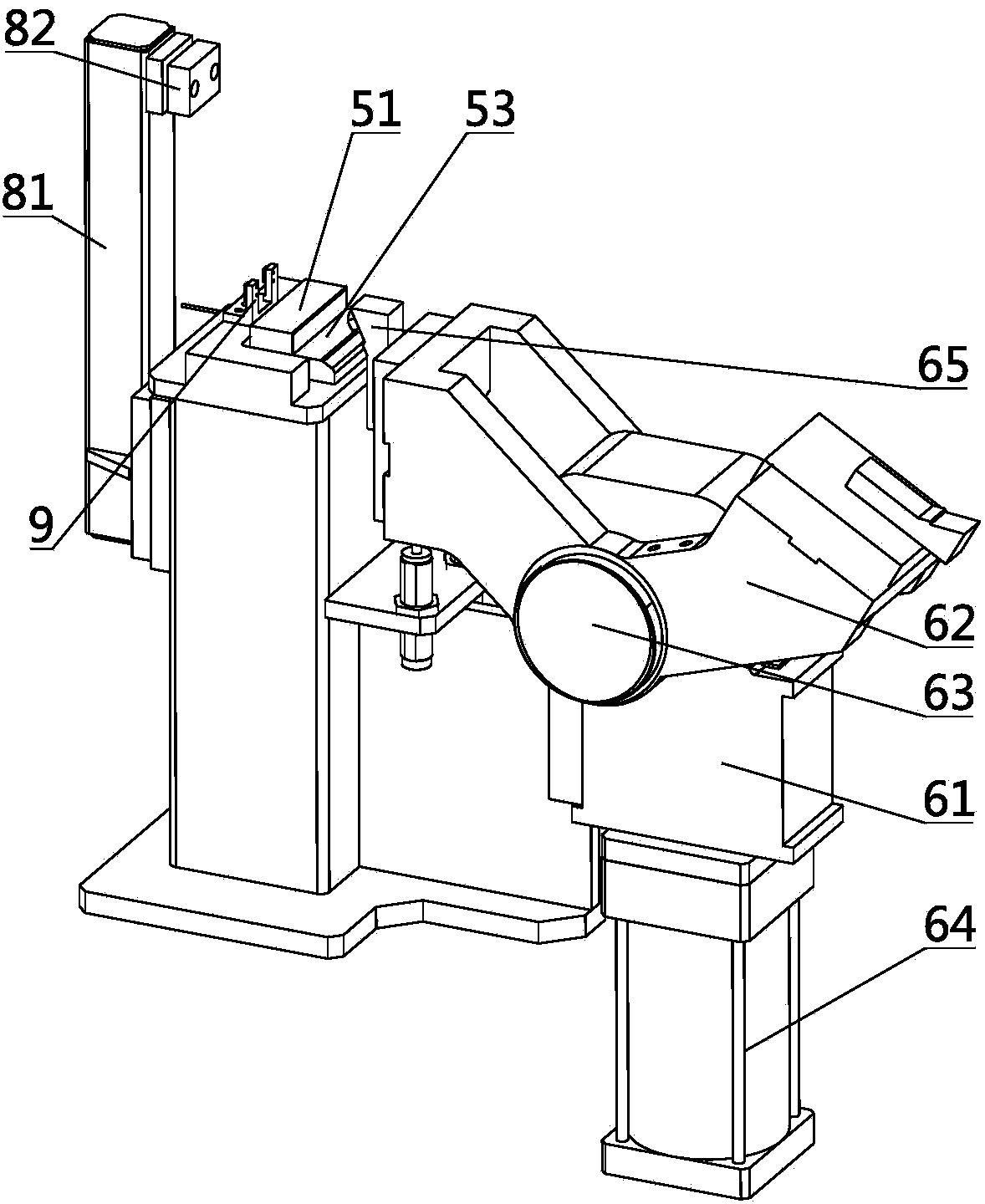

[0028] Such as figure 1 As shown, the quick positioning and clamping system for the gripper clamp assembly of the flexible body welding line designed by the present invention, the gripper clamp assembly includes a frame 2, and the gripper clamp 11 is provided on the said frame 2; the quick positioning The clamping system includes at least four uprights 3 installed on the welding line platform 1 for carrying the frame 2; at least two uprights 3 located on the same side of the center line of the welding line platform 1 are respectively provided with three-way positioning mechanisms 4 and two-way positioning mechanism 5; each of the side walls of the column 3 located outside the welding line platform 1 is provided with a pressing mechanism 6 that presses the above-mentioned three-way positioning mechanism 4 and two-way positioning mechanism 5. Further, the two opposite columns 3 on both sides of the welding line platform 1 are respectively provided with a three-way positioning me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com