Welding method for multi-spot welding with welding wire equally divided welding head

A welding method and welding head technology, which is applied in the field of wire and cable welding devices, can solve problems such as long welding heating time, deformation, and low welding efficiency, and achieve the effects of shortening welding time, concise process steps, and improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

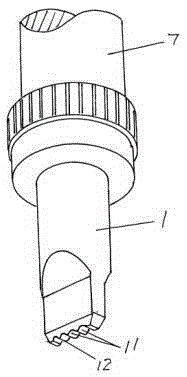

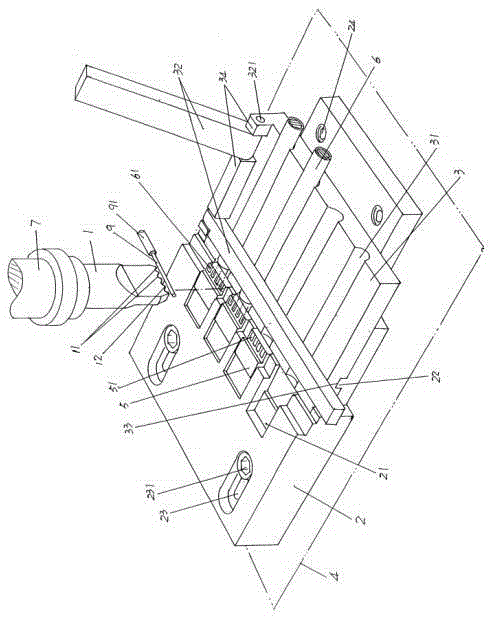

[0022] please see Figure 1 to Figure 3 , the conductor 61 of the wire 6 and the welding point 51 of the pad 5 implement the welding process as follows:

[0023] A) Equipped with a fixture structure consisting of figure 2 Schematically, it includes a base plate 2 and a wire positioning plate 3, the base plate 2 is fixed on the welding workbench 4, and the base plate 2 is facing upwards and at a position corresponding to the long side direction of the wire positioning plate 3 in a spaced state. There is a pad accommodating cavity 21, and the wire positioning plate 3 is positioned on the right end of the base plate 2 at a position corresponding to the right side of the pad accommodating cavity 21, and is parallel to the short side of the wire positioning plate 3 on the wire positioning plate 3 The direction is to set up wire embedding grooves 31 in a spaced state, the number of wire embedding grooves 31 is equal to the number of pad accommodation cavities 21 and the position c...

Embodiment 2

[0029] Only change the dwell time of the welding head body 1 on the conductor 61 in step D) to 0.2 seconds, and the rest are the same as the description of the first embodiment.

Embodiment 3

[0031] Only change the dwell time of the welding head body 1 on the conductor 61 in step D) to 0.4 seconds, and the rest are the same as the description of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com