Grouting device for controlling settlement of height railroad bed and grouting method

A technology of grouting device and railway subgrade, which is applied in the direction of road, soil protection, infrastructure engineering, etc., can solve the problems of large variation of grouting pressure, large equipment vibration, inability to accurately control grouting pressure, etc., to reduce vibration , the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

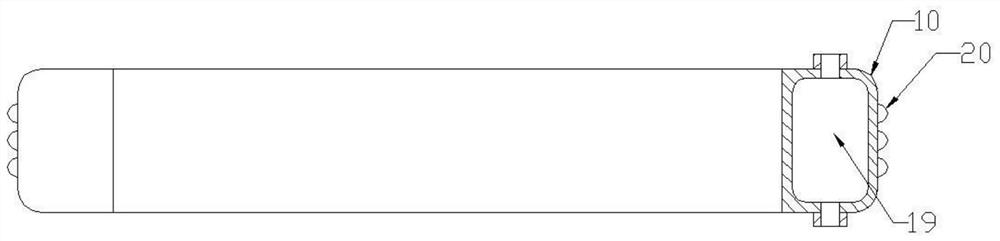

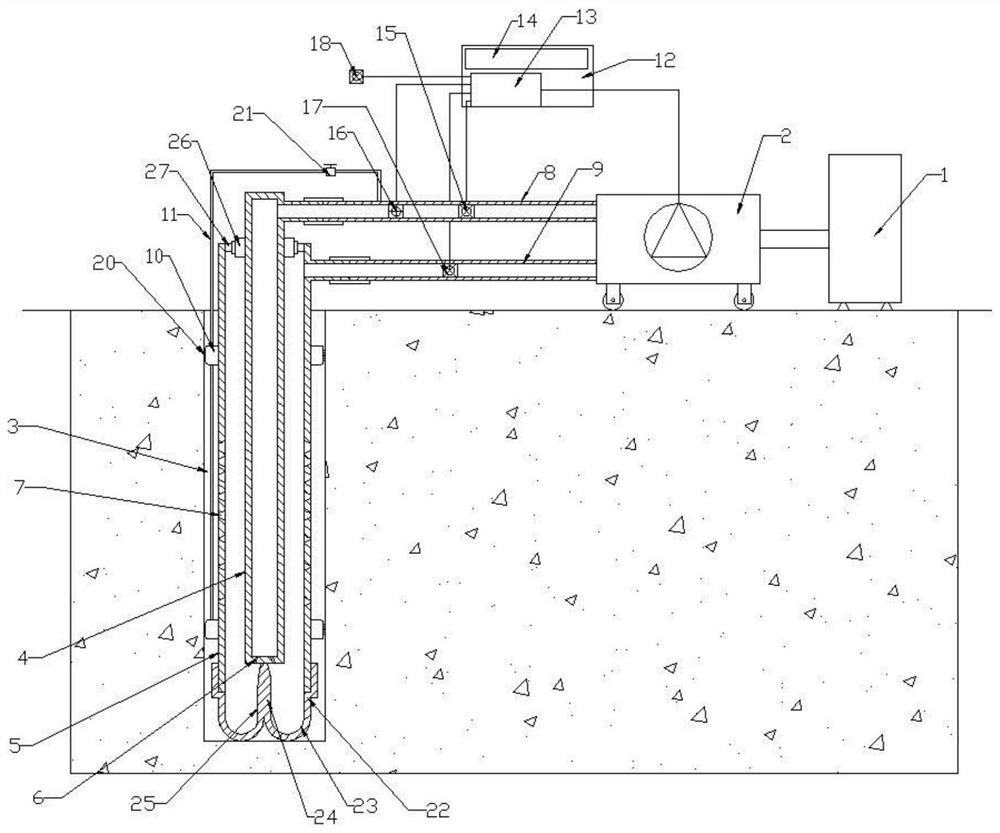

[0048] Such as figure 1 with figure 2 As shown, this embodiment provides a double-layer self-circulating pressure-maintaining grouting device, including a grouting machine 1, a grouting pump 2 and a grouting pipe 3, and the grouting pump 2 is communicated with the grouting machine 1, so that The grouting pipe 3 includes an inner pipe 4 and an outer pipe 5. The top of the inner pipe 4 is fixedly provided with a fixed disk 26, and the two ends of the outer pipe 5 are open structures, and a fixed ring 27 is arranged at the upper open end. The fixed disk 26 and The fixing ring 27 is threaded and connected, so that the outer pipe 5 is placed on the outer surface of the inner pipe 4; the top of the inner pipe 4 is connected with the connecting pipe 8, and the upper part of the outer pipe 5 sidewall is connected with a circulation pipe 9, and the connecting pipe 8 And the circulation pipe 9 is connected with the outlet and return port of the external grouting pump 2, thereby formin...

Embodiment approach 3

[0054] This embodiment, as another basic embodiment of the present invention, discloses a grouting method for controlling the settlement of a high-grade railway embankment: comprising the following steps:

[0055] S1. Drill the grouting pipe installation holes from both sides of the high-speed railway subgrade to the grouting area directly below the subgrade; and ensure that the grouting pipe installation holes on the left and right sides are drilled alternately;

[0056] S2. Install the grouting pipes in the grouting pipe installation holes, and at the same time group the grouting pipes according to the requirements of the grouting pressure and equipment power, and connect the same group of grouting pipes to the same set of grouting devices;

[0057] S3. Drill a monitoring hole from one side of the railway subgrade. The terminal of the monitoring hole is located between the Pearl River area and the subgrade; install the soil deformation monitoring sensor in the monitoring hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com