Food waste crushing device

A technology of crushing device and kitchen waste, applied in grain processing, solid waste removal and other directions, can solve the problems of stuck, not easy to fall, poor crushing effect, etc., and achieve the effect of eliminating severe vibration and avoiding chain loosening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

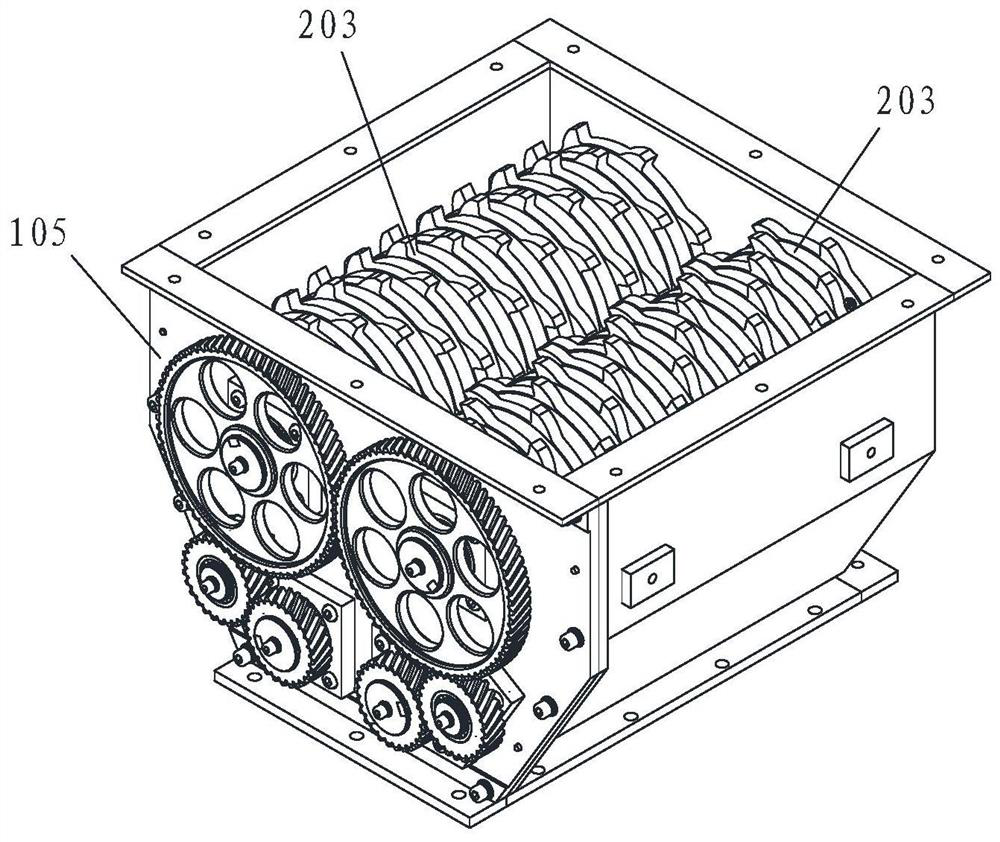

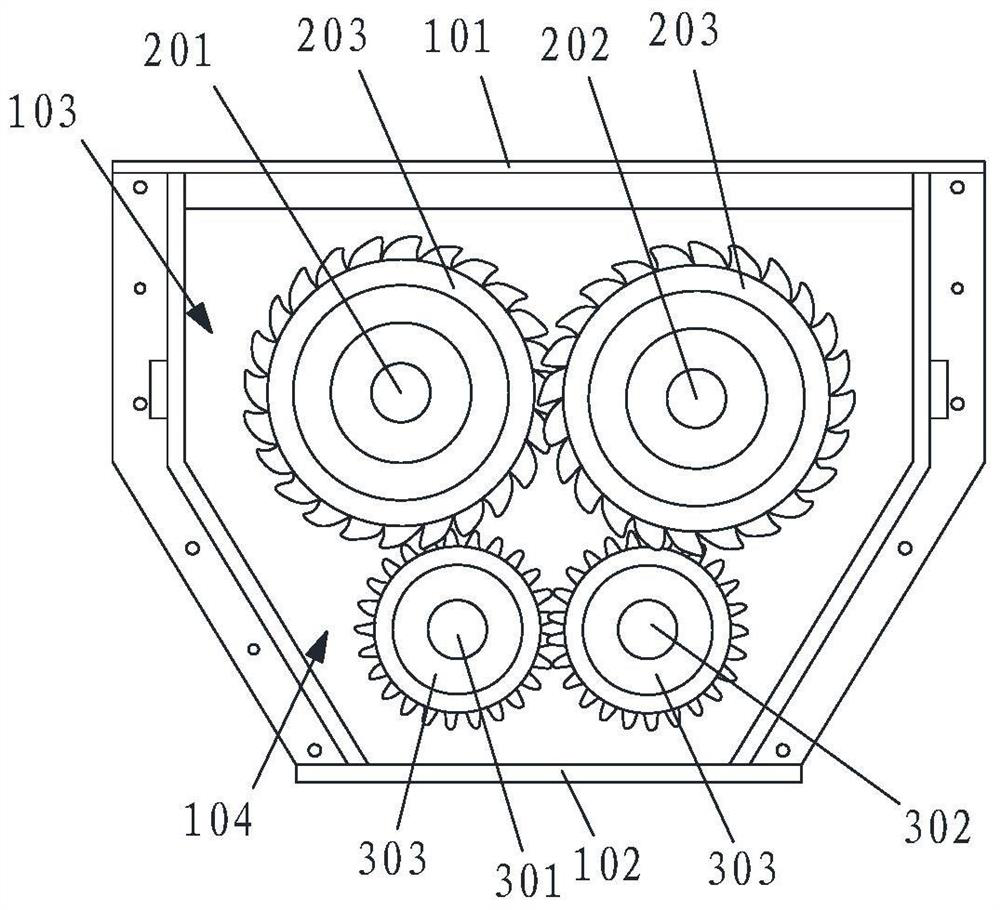

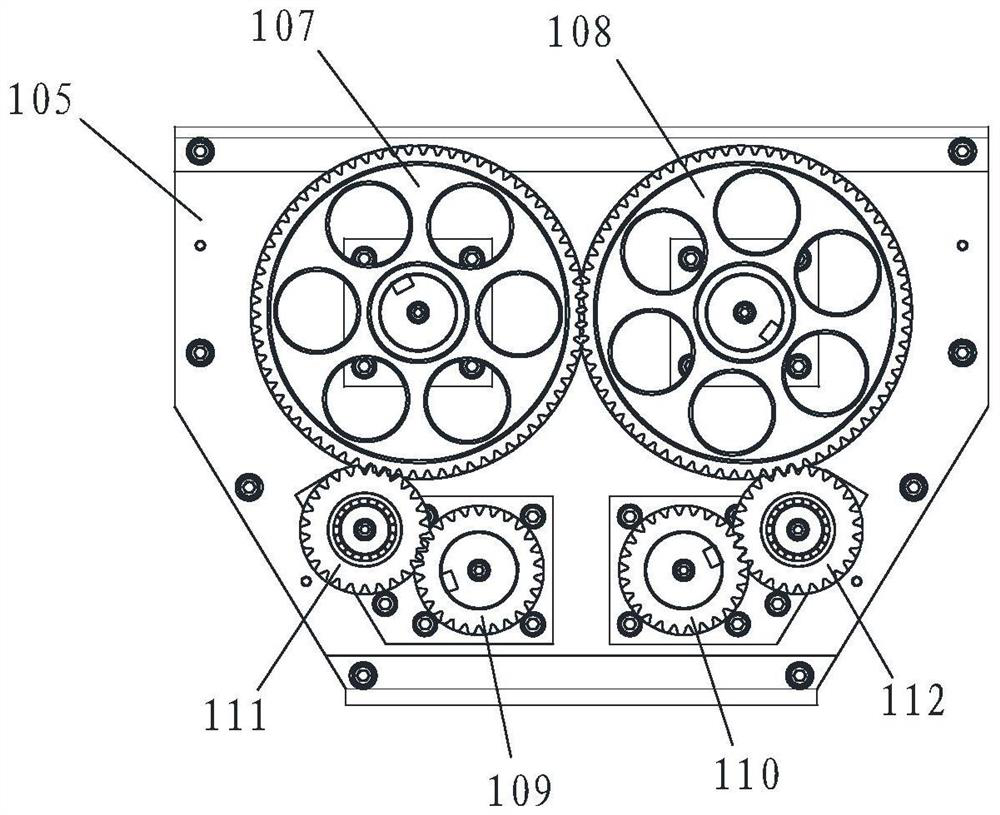

[0042] combine Figure 1 to Figure 4 As shown, the food waste crushing device includes a crushing chamber, a first-stage crushing roll set, and a second-stage crushing roll set.

[0043] The upper part of the crushing chamber is provided with a material inlet 101, and the lower part of the crushing chamber is provided with a discharge port 102.

[0044] Both the first-stage crushing roll set and the second-stage crushing roll set are located inside the crushing cavity, and the first-stage crushing roll set is located above the second-stage crushing roll set.

[0045] The kitchen waste enters the crushing cavity through the feed port 101, and then is squeezed into small particles under the crushing action of the first-stage crushing roll set and the second-stage crushing roll set, and finally discharged through the discharge port 102.

[0046] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com