Anti-freezing mashed shrimp and preparation method thereof

A technology of antifreeze and shrimp slippery, applied in food preparation, food science, application, etc., can solve the problems that restrict the development of Penaeus vannamei aquaculture, cannot meet the market demand, and the processing output is not large, so as to achieve good nutritional value and The effect of commercial value, excellent taste and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

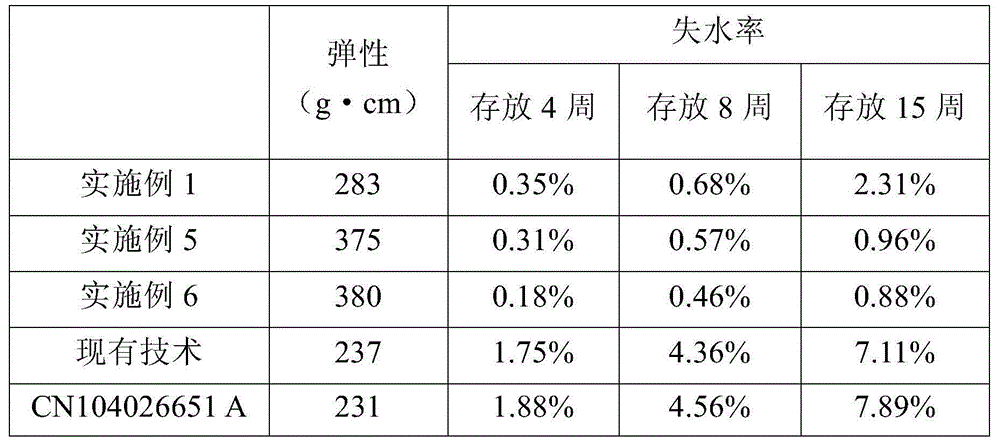

Embodiment 1

[0032] The shrimp slip provided by the present embodiment is processed by the method comprising the following steps:

[0033] (1) Raw material pretreatment: thaw the shrimp meat at 0°C for 7 hours, add it to a meat grinder, and grind it into granules through a 6mm orifice plate;

[0034] (2) raw material preparation: take by weighing 75 parts of shrimp meat in step (1), take by weighing 10 parts of potato starch, 5 parts of chilled egg white, 5.9 parts of water, 1.5 parts of salt, 2.5 parts of white granulated sugar, 0.05 part of compound phosphate, 0.05 parts of sorbitol;

[0035] (3) Stirring: using the raw materials weighed in step (2), under the condition of 7°C, at first fully stir the shrimp meat and compound phosphate with a frequency conversion mixer at a low speed, then add salt and stir at a high speed, and finally mix the potato starch, Add iced egg whites, water, salt, white granulated sugar, and sorbitol and stir evenly at low speed.

[0036] (4) The slurry obta...

Embodiment 2

[0039] (1) Raw material pretreatment: thaw the shrimp meat at 5°C for 6 hours, put it into a meat grinder, grind it through a 7mm orifice plate to make granules;

[0040] (2) Raw material preparation: take by weighing 80 parts of shrimp meat in step (1), take by weighing 8 parts of potato starch, 4 parts of ice egg white, 4.72 parts of water, 1.2 parts of salt, 2 parts of white granulated sugar, 0.04 part of compound phosphate, 0.04 parts of sorbitol;

[0041] (3) Stirring: using the raw materials weighed in step (2), under the condition of 6°C, at first fully stir the shrimp meat and compound phosphate with a frequency conversion mixer at a low speed, then add salt and stir at a high speed, and finally mix the potato starch, Add iced egg whites, water, salt, white granulated sugar, and sorbitol and stir evenly at low speed.

[0042] (4) The slurry obtained in step (3) is sterilized, packaged, and double-screw quick-frozen to obtain a frost-resistant shrimp slippery product. ...

Embodiment 3

[0044] (1) Raw material pretreatment: thaw the shrimp meat in an environment of 10°C for 5 hours, add it to a meat grinder, and grind it into granules through an 8mm orifice plate;

[0045] (2) Raw material preparation: take by weighing 85 parts of shrimp meat in step (1), take by weighing 6 parts of potato starch, 3 parts of chilled egg whites, 3.44 parts of water, 1 part of salt, 1.5 parts of white granulated sugar, 0.03 parts of compound phosphate, 0.03 parts of sorbitol;

[0046] (3) Stirring: using the raw materials weighed in step (2), under the condition of 5°C, at first fully stir the shrimp meat and compound phosphate with a frequency conversion mixer at a low speed, then add salt and stir at a high speed, and finally mix the potato starch, Add iced egg whites, water, salt, white granulated sugar, and sorbitol and stir evenly at low speed.

[0047] (4) The slurry obtained in step (3) is sterilized, packaged, and double-screw quick-frozen to obtain a frost-resistant s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com