Dye-sensitized solar cell element for low luminance

A pigment sensitization, solar cell technology, used in electrical components, battery pack parts, capacitor parts and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

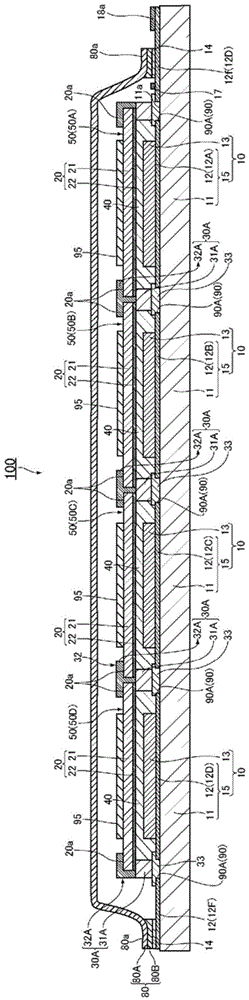

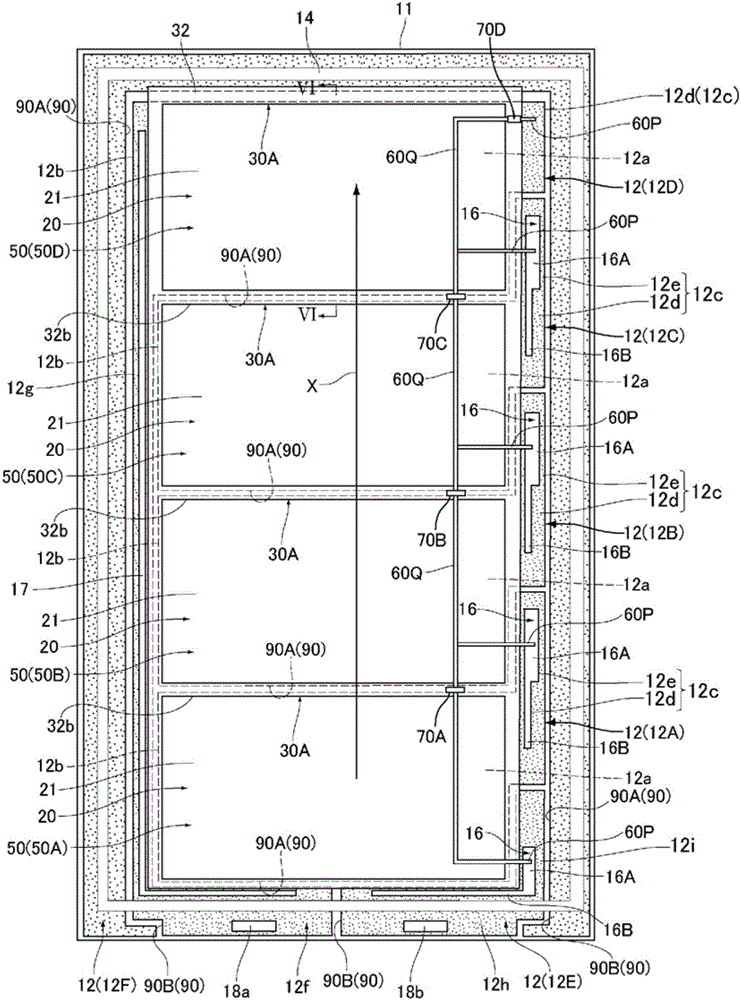

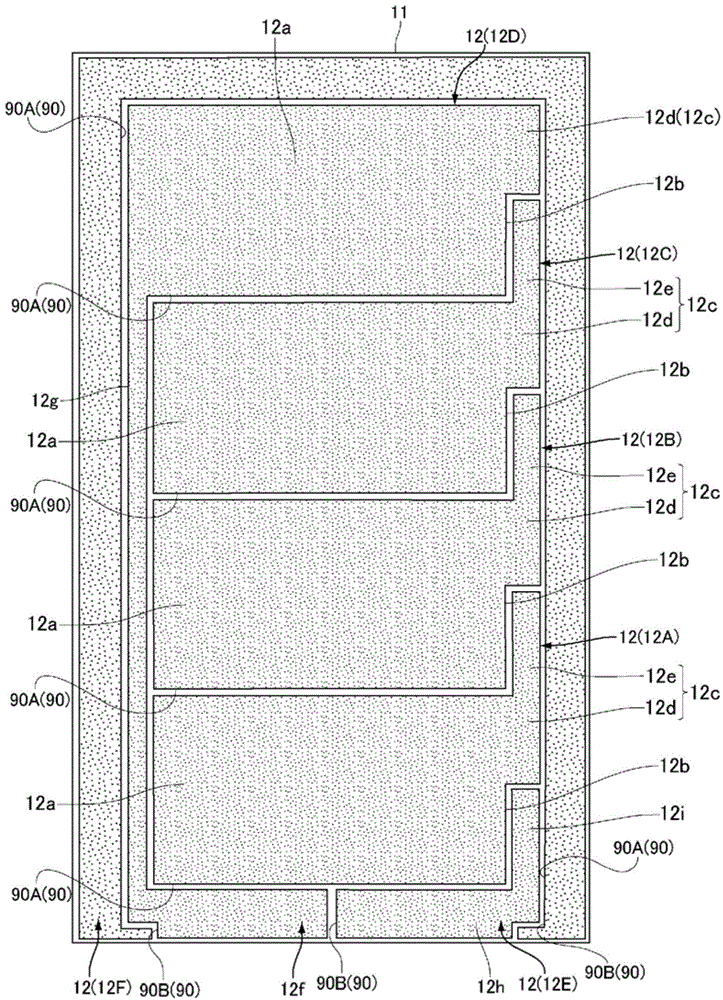

[0219] First, a laminated body formed by forming a transparent conductive film made of FTO with a thickness of 1 μm on a transparent substrate made of glass with a thickness of 1 mm was prepared. Next, if image 3 shown, using CO 2 Grooves 90 are formed in the transparent conductive film 12 using a laser (V-460 manufactured by Universal Systems Co., Ltd.), and transparent conductive films 12A to 12F are formed. At this time, the width of the groove 90 was 1 mm. In addition, each of the transparent conductive films 12A to 12C is formed to have a quadrangular main body of 4.6 cm×2.0 cm and a protrusion protruding from one side edge of the main body. In addition, the transparent conductive film 12D is formed to have a quadrangular main body of 4.6 cm×2.1 cm, and a protrusion protruding from one side edge of the main body. In addition, among the transparent conductive films 12A to 12D, the protruding portions 12c of the three transparent conductive films 12A to 12C are composed...

Embodiment 2

[0248] A DSC module was produced in the same manner as in Example 1 except that the first current collector wiring 17 was not formed.

Embodiment 3

[0250] A DSC module was produced in the same manner as in Example 1 except that the connecting portion 14 was not formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com