Flip-chip bonding electrode structure of surface-type semiconductor laser device

A laser device and electrode structure technology, which is applied in the direction of semiconductor lasers, semiconductor devices, laser components, etc., can solve the problems of increasing the distance between P-type electrodes and N-type electrodes, and the height difference between P-type electrodes and N-type electrodes. Effects of increased distance, prevention of short-circuit conditions, and simple packaging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

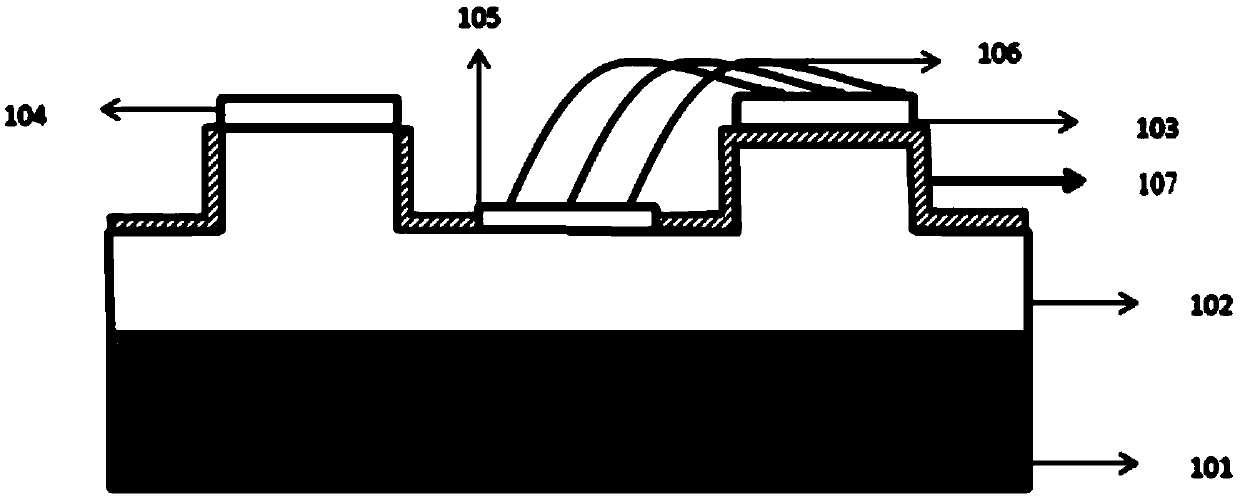

[0024] Such as figure 1 As shown, the surface type semiconductor laser device flip chip electrode structure of the present invention includes: sapphire substrate (101), epitaxial growth layer (102), N' type electrode (103), P type electrode (104), N type electrode (105), gold wire (106) and insulating layer (107).

[0025] Described sapphire substrate (101) is the substrate that grows other structures as laser medium, and main component is aluminum oxide (Al 2 o 3 ); and the sapphire substrate (101) is a trigonal crystal system with a refractive index of 1.76-1.77, is a heterogeneous body, has no cleavage, and is developed by cleavage.

[0026] The epitaxial growth layer (102) is deposited and grown layer by layer on the sapphire substrate by metal organic compound chemical vapor deposition.

[0027] The N-type electrode (105) and the P-type electrode (104) are etched by photolithography to epitaxial growth layer, and then use evaporation or sputtering to cover one or more ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com