A design method for inner tank height of LNG storage tank

A design method and storage tank technology, applied in calculations, special data processing applications, instruments, etc., can solve problems such as poor adaptability, complicated calculation process, and difficult to use formula calculations to achieve reasonable design and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

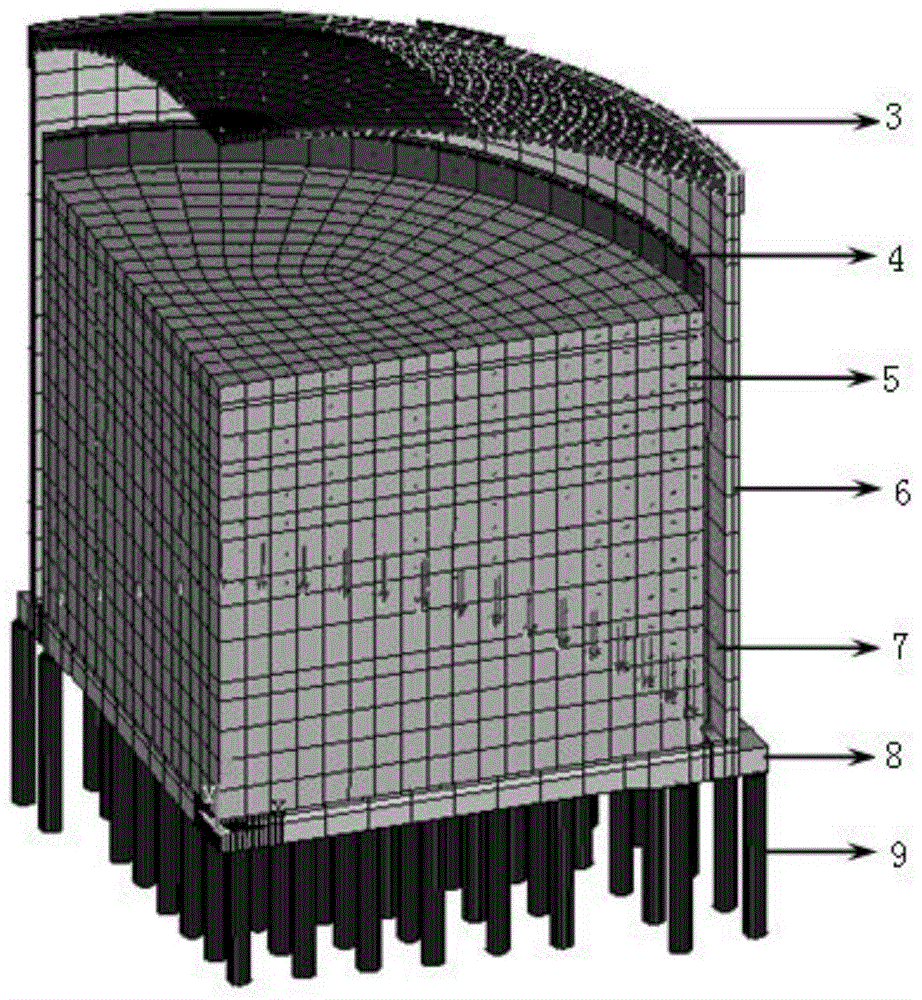

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

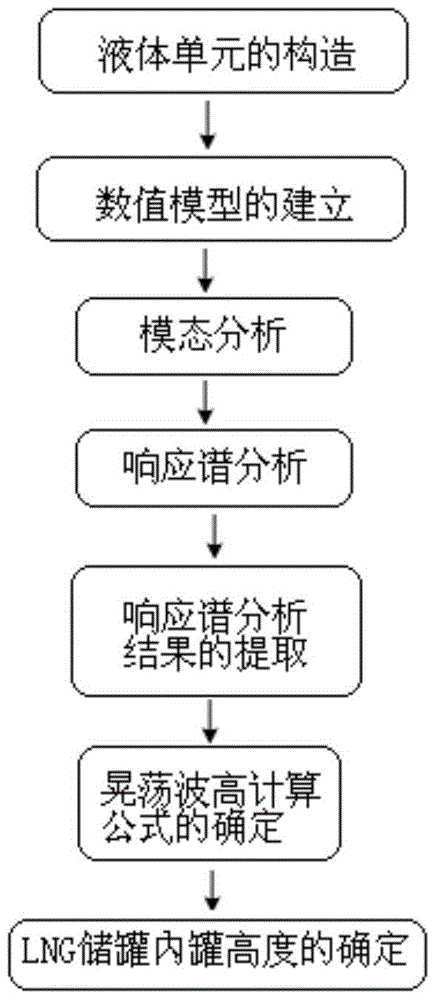

[0021] Such as figure 1 As shown, the present invention provides a method for designing the height of an inner tank of an LNG storage tank, comprising the following steps:

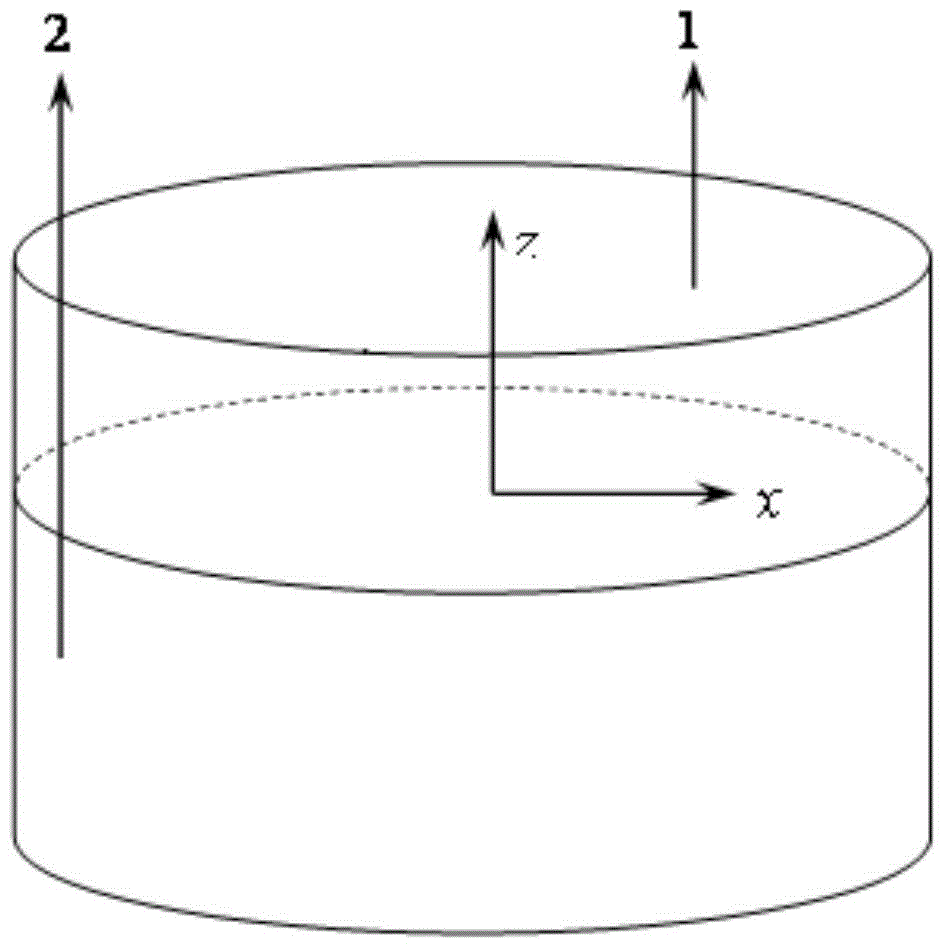

[0022] 1) The structure of the liquid unit: such as figure 2As shown, set a cylindrical container 1 containing a certain volume of liquid 2, use finite element software to discretize the liquid 2 into small hexahedral units, assign LNG material properties to the hexahedral units, and set a stiffness K on its surface S The spring simulates the free surface effect of the liquid, and the spring stiffness K is determined by the equation of motion of the liquid S for:

[0023] K s =ρA F (C x g x +C y g y +C z g z ) (1)

[0024] In the formula, ρ is the density of the liquid, AF is the surface area of the liquid, (x, y, z) is the spatial rectangular coordinate with the or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com