The screw of the screw vacuum pump

A screw vacuum pump and screw technology are applied to the screw vacuum pump and the screw of the screw vacuum pump. field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

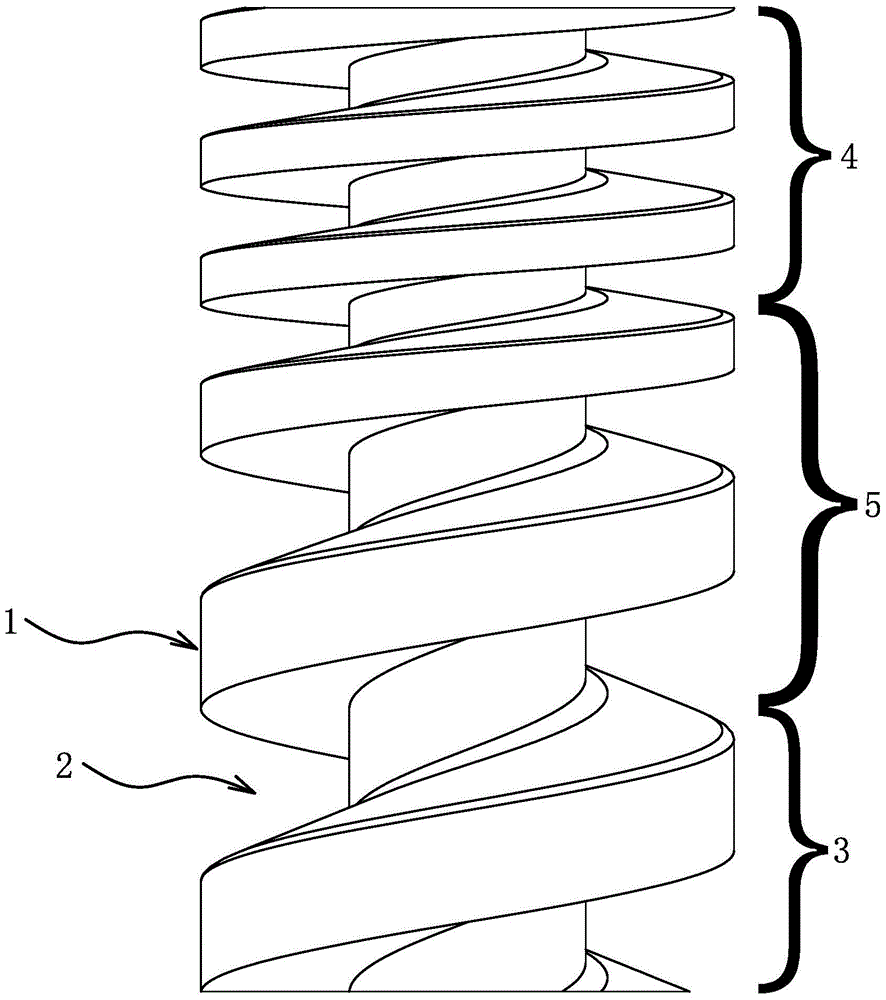

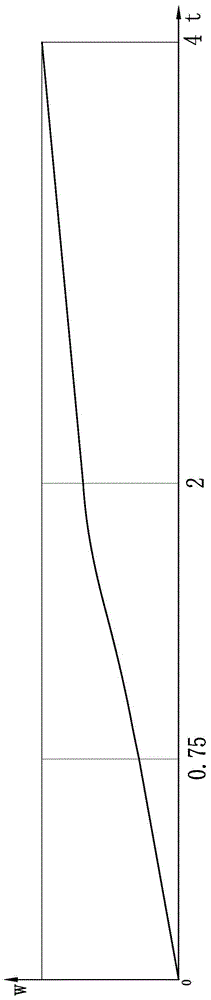

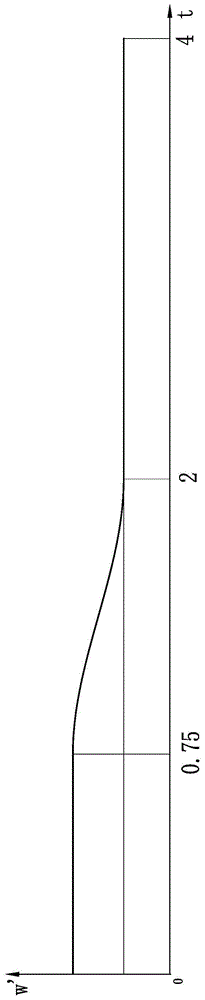

[0030] Such as figure 1 As shown, the screw of the screw vacuum pump includes a cylindrical rod body 1, a spiral groove 2 is opened on the outer surface of the rod body 1, and the two ports of the spiral groove 2 are respectively located on both ends of the rod body 1. One end of the rod body 1 is The suction part 3, the other end is the exhaust part 4, and the compression transition part 5 is between the suction part 3 and the exhaust part 4; the pitch of the spiral groove 2 on the suction part 3 is constant, and the helical The pitch of the groove 2 is constant, the pitch of the spiral groove 2 on the exhaust part 4 is smaller than the pitch of the spiral groove 2 on the suction part 3; one end of the spiral groove 2 on the compression transition part 5 is connected with the spiral groove 2 on the suction part 3, The other end is in contact with the helical groove 2 on the exhaust part 4, and the pitch of the helical groove 2 on the compression transition part 5 gradually de...

Embodiment 2

[0042] The structure and principle of this embodiment are basically the same as that of Embodiment 1, except that the number of winding turns of the spiral groove 2 is 4 turns, and the number of turns of the spiral groove 2 on the suction part 3 is 1 turn; the compression transition part 5 The number of turns of the upper spiral groove 2 is 1.25 turns, and the number of turns of the upper spiral groove 2 of the exhaust part 4 is 1.75 turns.

[0043] The vacuum pump using the variable-pitch screw reduces the ultimate vacuum degree by increasing the number of turns of the helical groove 2 on the compression transition part 5; at the same time, the length of the screw running heat is increased, the temperature of the screw and the internal working temperature of the vacuum pump are reduced, and the deformation of the screw is reduced. The machining accuracy and manufacturing cost of the screw are reduced, and the performance stability of the vacuum pump can be ensured.

[0044]Th...

Embodiment 3

[0051] The structure and principle of this embodiment are basically the same as that of Embodiment 1, except that the number of winding turns of the spiral groove 2 is 5.5 turns, and the number of turns of the spiral groove 2 on the suction part 3 is 1 turn; the compression transition part 5 The number of turns of the upper spiral groove 2 is 1 turn, and the number of turns of the upper spiral groove 2 of the exhaust part 4 is 3.5 turns.

[0052] The vacuum pump using the variable pitch screw reduces the ultimate vacuum degree by increasing the number of turns of the helical groove 2 on the exhaust part 4; at the same time, it increases the heating length of the screw, reduces the temperature of the screw and the internal working temperature of the vacuum pump, and then reduces the deformation of the screw, thus The machining accuracy and manufacturing cost of the screw are reduced, and the performance stability of the vacuum pump can be ensured.

[0053] The nonlinear change ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com