Underground natural gas storage injection-production pipe column designing method

An injection-production pipe string and design method technology, applied in casing, drill pipe, calculation, etc., can solve the problems of not considering the compression resistance performance of pipe string joints and not considering the compressive load of pipe strings, so as to ensure long-term safe operation, The effect of improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The content of the present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

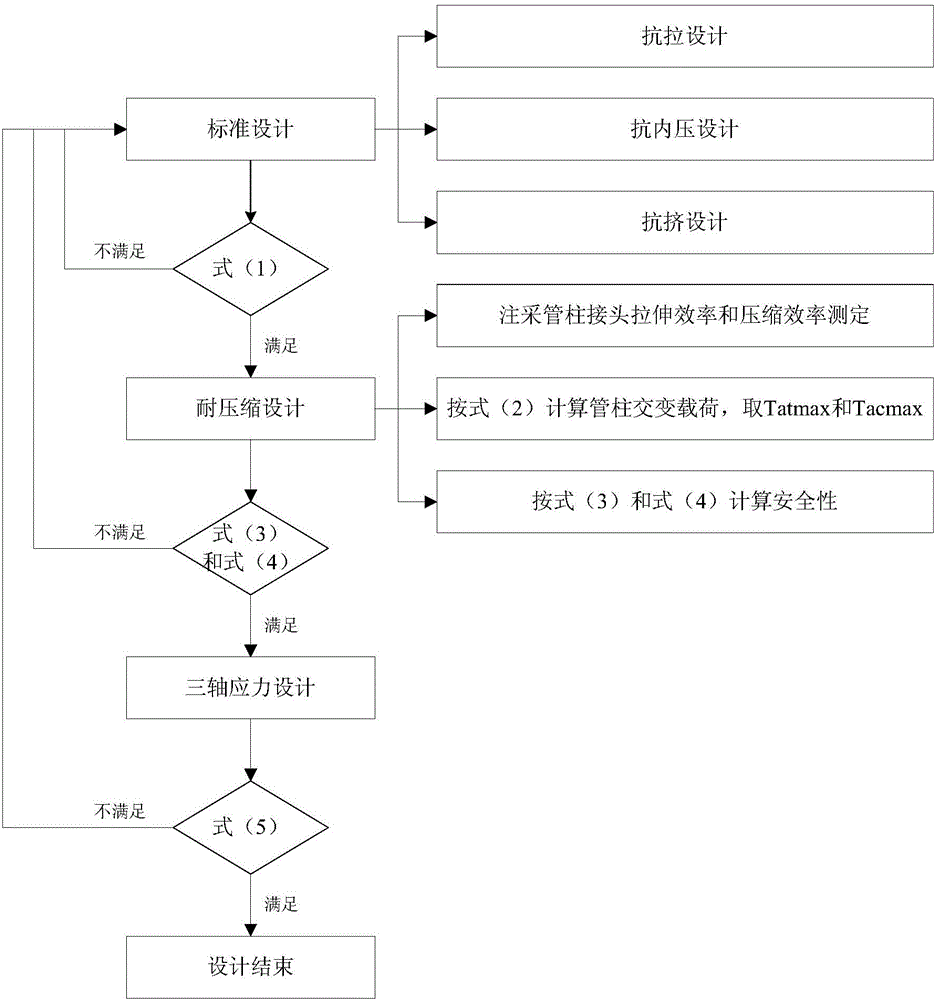

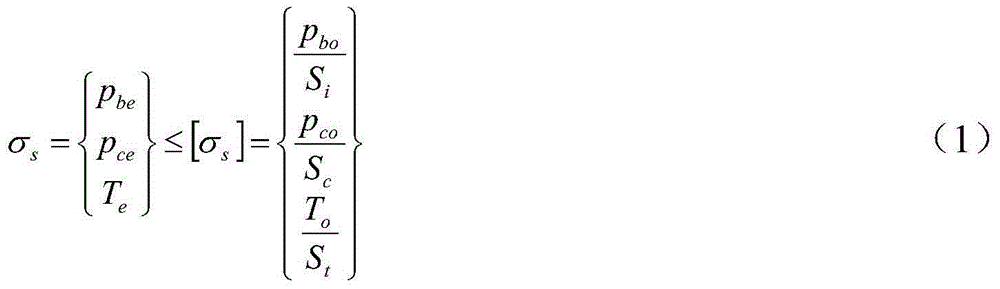

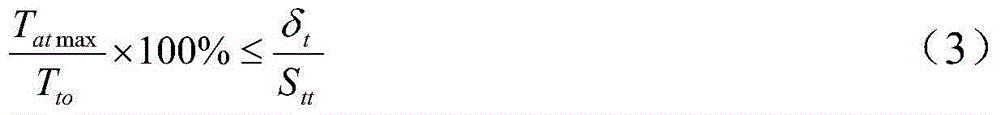

[0027] The invention is mainly used for the design of the injection-production string of the underground gas storage, and mainly includes a standard design module, a compression resistance design module and a triaxial stress design module. Standard design module, that is, according to the design methods described in the standard "SY / T 5724-2008 Casing String Structure and Strength Design" and "Drilling Manual (Party A)", conduct preliminary design of the pipe string to meet the requirements of conventional operations (such as pressure test, etc.); the compression resistance design module is the key point of the design, comprehensively considering the friction caused by the pipe body's own weight, temperature effect, pressure effect (piston effect, expansion effect, bending effect) and fluid flow during the operation process. The impact of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com