Heat Treatment Method for Gear Tapered Roller Bearing and Bearing Toothed Outer Ring

A technology for tapered roller bearings and gears, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problems of low bearing capacity and power density, large gearbox volume, etc., and achieve high bearing capacity and power density, The effect of small size and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

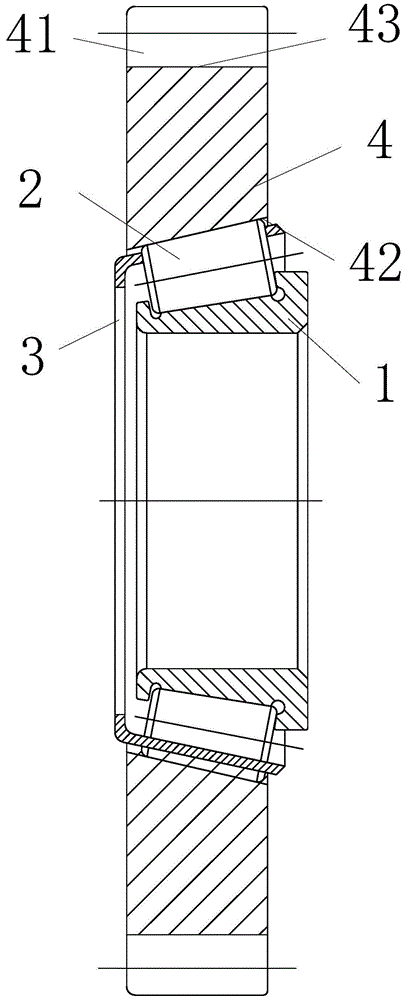

[0016] as attached figure 1 Shown: a tapered roller bearing for gears, including an inner ring 1, a rolling element group 2 and a cage 3, and a toothed outer ring 4 of the bearing with a gear 41 formed integrally around the outside.

[0017] The radial distance between the large end of the inner hole 42 of the toothed outer ring 4 of the bearing and the dedendum circle 43 of the gear 41 is three times the modulus of the gear 41 .

[0018] The material of the toothed outer ring 4 of the bearing is GCr15.

[0019] The hardness at the inner hole 42 is HRC63; the hardness at the gear 41 is HRC50. It can meet the different working requirements of the inner hole of the toothed outer ring of the bearing and the hardness of the gear at the same time.

[0020] A heat treatment method for a bearing toothed outer ring 4, the outer side of the bearing toothed outer ring 4 is pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com