Treatment method for zero discharge of high-hardness high-salinity wastewater

A treatment method and high-salt technology, applied in the field of water treatment, can solve the problems of inability to achieve high-level reuse and zero discharge, achieve the effects of improving recycling rate, stabilizing effluent water quality, and solving environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

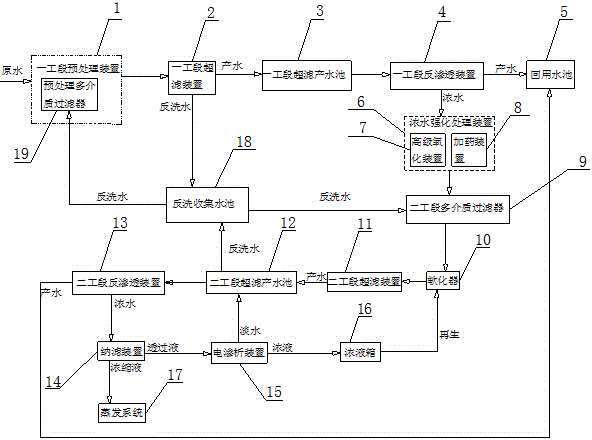

[0021] Combine below figure 1 The present invention will be further described with specific embodiments.

[0022] A zero-discharge treatment method for high-hardness and high-salt wastewater, using such as figure 1 The device shown comprises the following steps:

[0023] 1) The high-hardness wastewater discharged by the paper mill meets the standard, the main water quality indicators are COD=60-80mg / L, hardness=800-1000, conductivity=5000-6000uS / cm, and the hardness and suspended solids are reduced by the first-stage pretreatment device 1 Content and COD pretreatment, the pretreatment device in the first section adopts pretreatment multi-media filter 19, coagulation and dosing slant plate sedimentation, and ozone treatment combination. After pretreatment, the main water quality indicators reach: COD=30mg / L, hardness= 200;

[0024] 2) The wastewater pretreated in step 1) enters the ultrafiltration device 2 of the first section and the reverse osmosis device 4 of the first se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com