High-efficiency sewage treating agent

A sewage treatment agent and high-efficiency technology, applied in water/sewage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc. The sodium corrosion inhibition performance is not ideal, the sterilization effect is not very ideal, etc., to achieve the effects of low cost, easy storage, and compact flocs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A high-efficiency sewage treatment agent, comprising the following components in parts by weight:

[0057] 15 parts of polymerized aluminum iron silicate;

[0058] 8 parts of activated alumina;

[0059] 8 parts bleaching powder;

[0060] 1 part of organic phosphonium salt scale inhibitor;

[0061] 2 parts of organic corrosion inhibitor;

[0062] 2 parts of acetic acid.

[0063] The organic phosphonate scale inhibitor is sodium organic phosphonate. When using, put the above components into the sewage separately to ensure uniform distribution.

Embodiment 2

[0065] The high-efficiency sewage treatment agent includes the following components in parts by weight:

[0066] 75 parts of polymerized aluminum iron silicate;

[0067] 22 parts of activated alumina;

[0068] 16 parts of bleaching powder;

[0069] 10 parts of organic phosphonium salt scale inhibitor;

[0070] 9 parts of organic corrosion inhibitor;

[0071] 10 parts of acetic acid.

[0072] The organic phosphonate scale inhibitor is sodium organic phosphonate. When using, put the above components into the sewage separately to ensure uniform distribution.

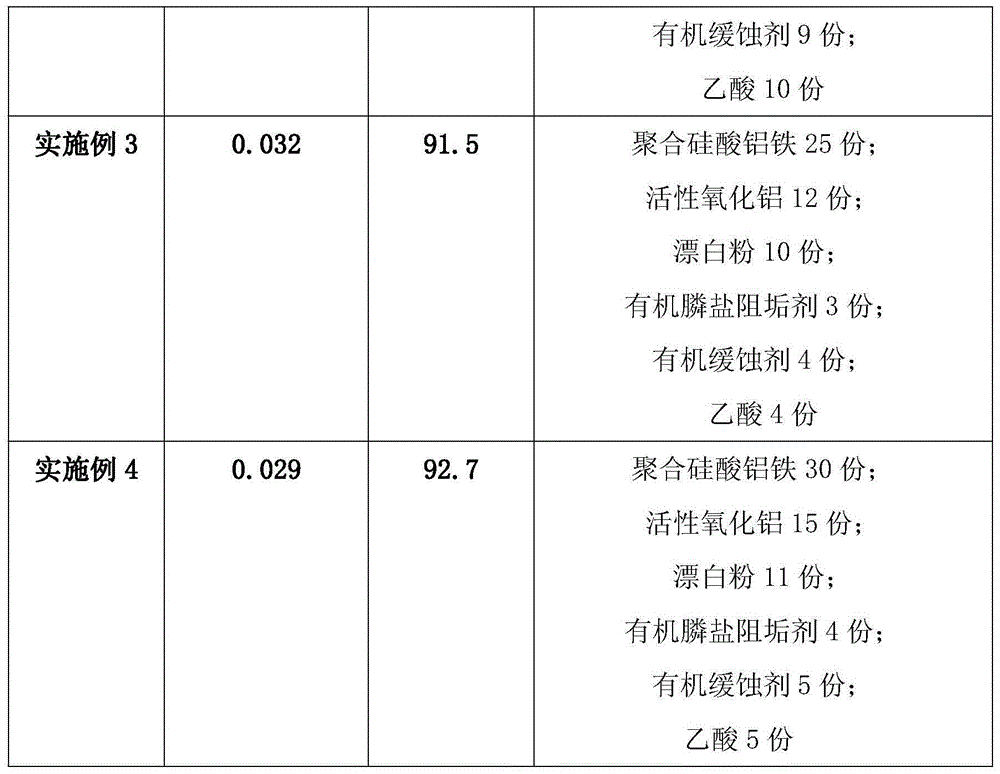

Embodiment 3

[0074] The high-efficiency sewage treatment agent includes the following components in parts by weight:

[0075] 25 parts of polymerized aluminum iron silicate;

[0076] 12 parts of activated alumina;

[0077] 10 parts of bleaching powder;

[0078] 3 parts of organic phosphonium salt scale inhibitor;

[0079] 4 parts of organic corrosion inhibitor;

[0080] 4 parts of acetic acid.

[0081] The organic phosphonate scale inhibitor is sodium organic phosphonate. When using, put the above components into the sewage separately to ensure uniform distribution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com