A tangential feed hobbing method for gear hobbing machines

A technology of tangential feeding and gear hobbing, which is applied to components with teeth, gear teeth, mechanical equipment, etc., can solve the problems of inability to automatically control the tangential displacement of the hob tool holder, low utilization rate, and high cost. Achieve the effects of improving production efficiency, recovering production losses and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

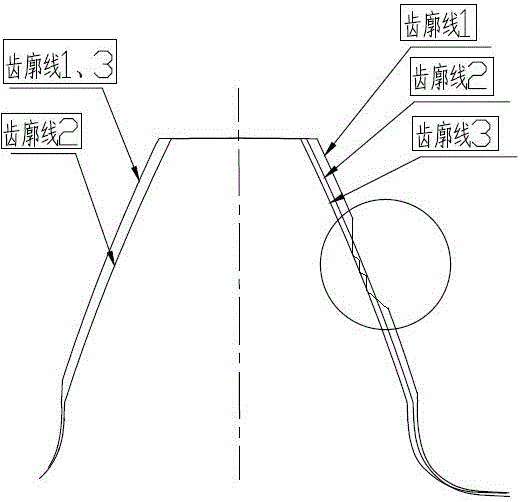

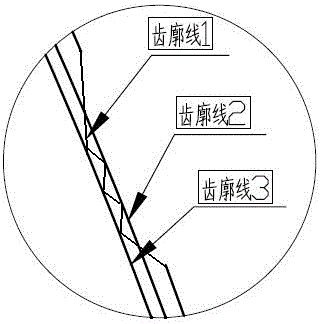

[0024] The gears in this example are hobbed by a gear hobbing machine, and the effective tooth width common normal of the gear after hobbing is required root circle maximum value df max =716.797mm, sub-circle pressure angle α=25°. However, during the gear hobbing process, the explosion occurred, resulting in defects on the tooth surface. The contour line after the explosion is as follows: figure 1 "Tooth Profile 1" shown in . In this case, if you continue to hob the gear in the normal way, the tooth profile after hobbing is as follows figure 1 "Tooth Profile 2" shown in the figure 2 Clearly visible tooth surface defects cannot be removed.

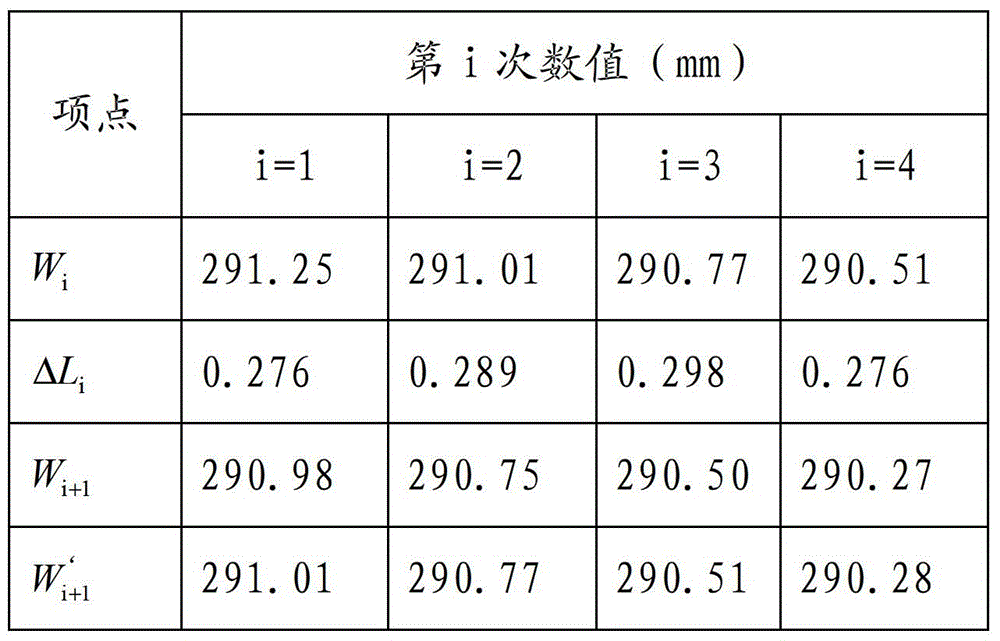

[0025] The tangential feed hobbing method for gear hobbing machine of the present embodiment, its ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com