Die for machining powder metallurgy multi-step part

A powder metallurgy, multi-step technology is applied in the field of molds for processing powder metallurgy multi-step parts, which can solve the problems of low machining accuracy and high cost, and achieve the effects of accurate machining dimensions and lower production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

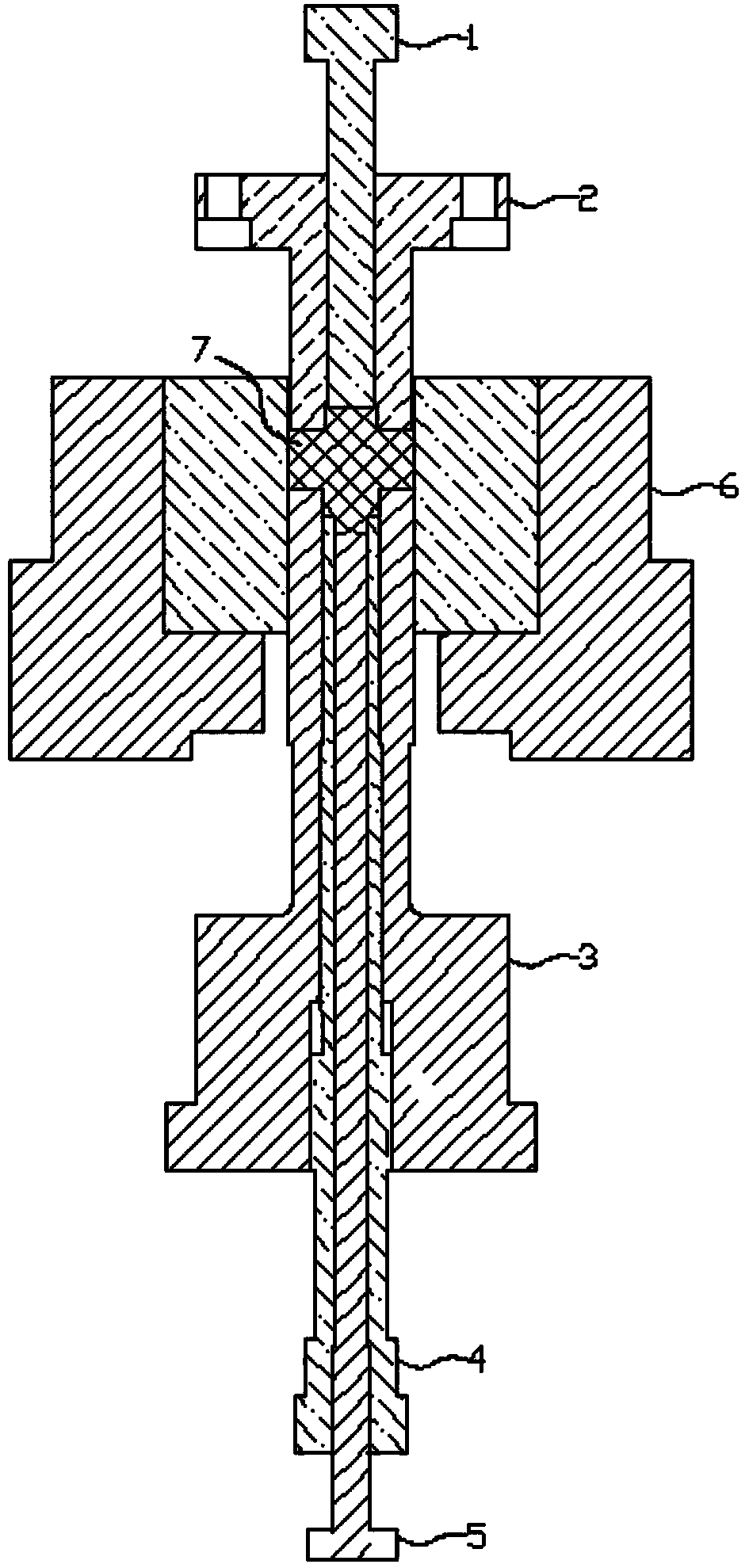

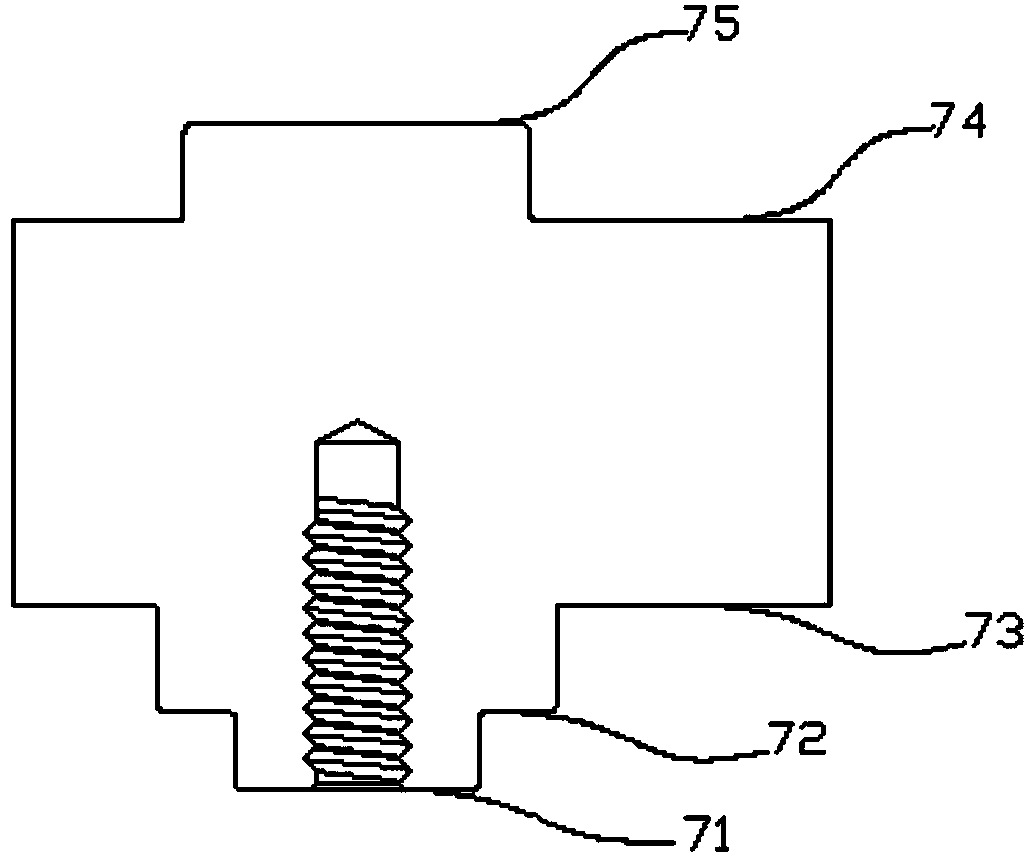

[0017] see figure 1 , a mold for processing powder metallurgy multi-step parts 7 in this embodiment includes a die 6 and a punch die assembly. The die 6 includes a die body and a die sleeve for fixing the parts. The die sleeve is provided with a first pass hole, the punch die assembly includes a first punch die 1, a second punch die 2, a third punch die 3, a fourth punch die 4 and a fifth punch die 5, and the second punch die 2 is located at the first punch die Above the first through hole, there is a second through hole for the first punch die 1 to enter, and the third punch die 3 is located below the first through hole, and a third pass for the fourth punch die 4 to enter is provided. Hole, the fourth punch die 4 is provided with the fourth through hole for the fifth punch die 5 to enter.

[0018] The mold processing process of the powder metallurgy multi-step pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com