Crankshaft end connection screw hole drilling aids

A technology for connecting screws and crankshafts, used in drilling/drilling equipment, manufacturing tools, drilling dies for workpieces, etc. and other problems, to achieve the effect of simple structure, simple manufacture and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

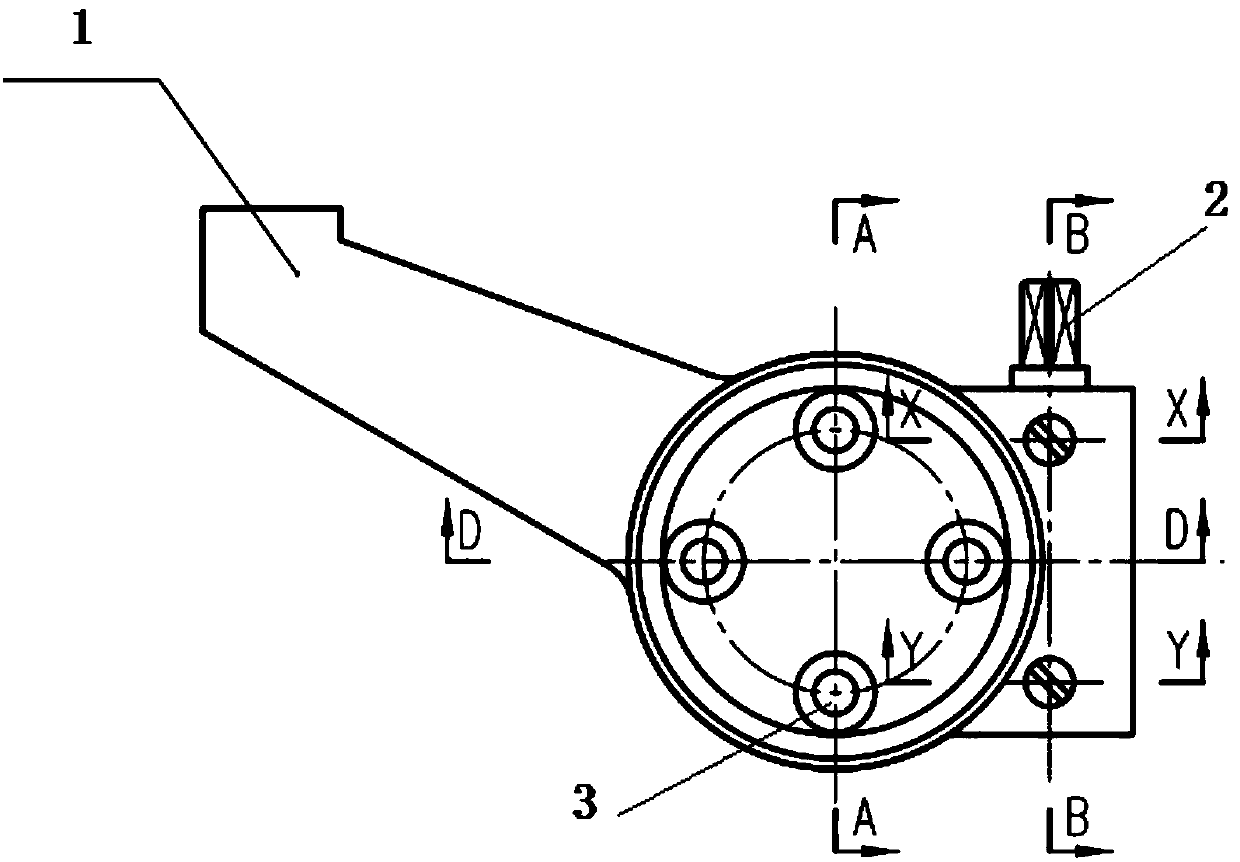

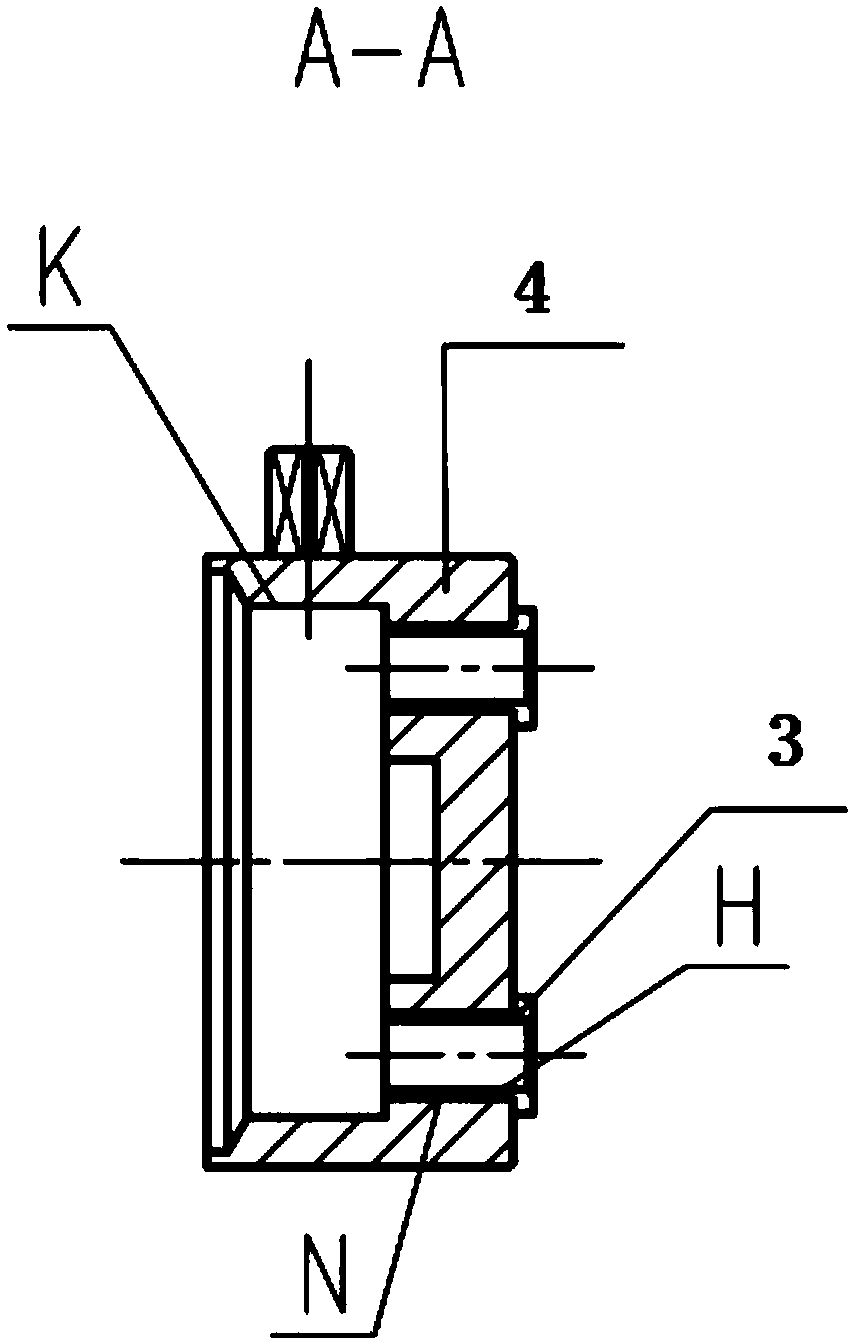

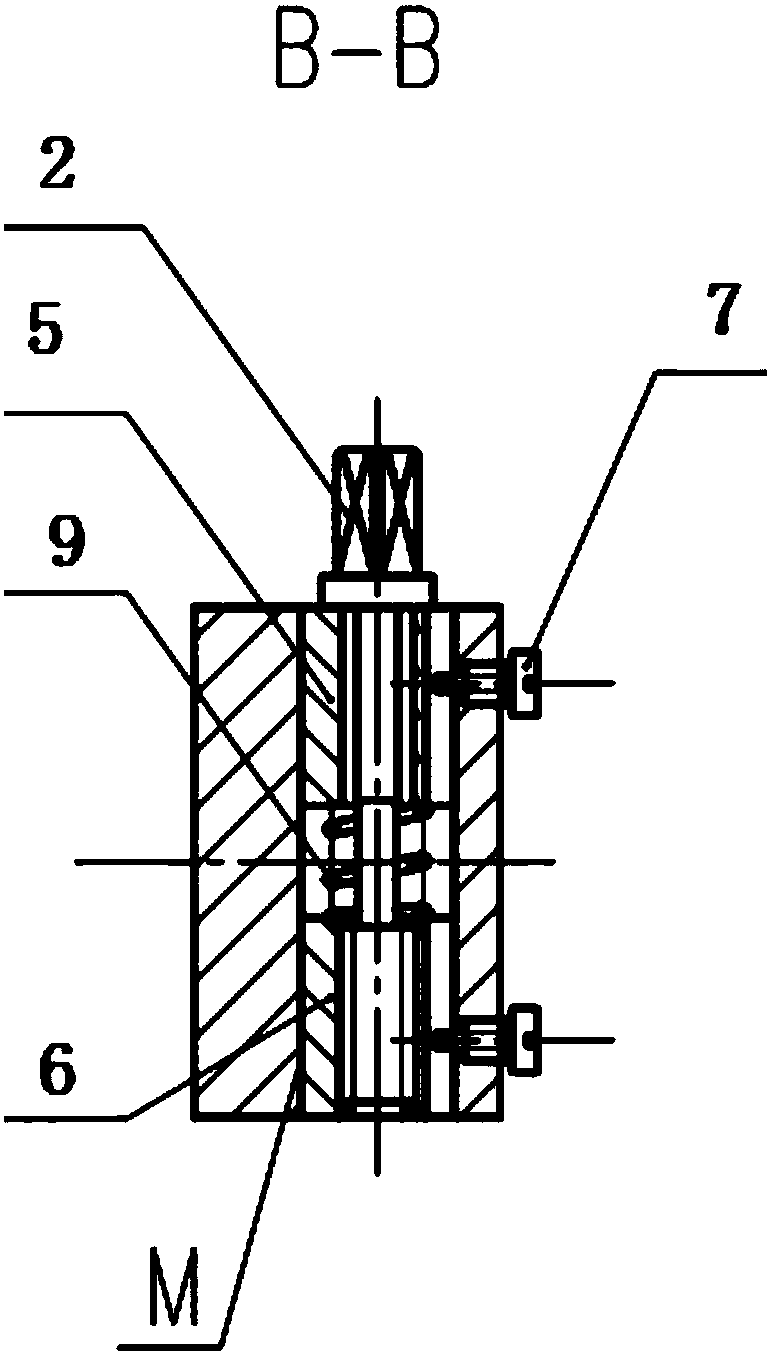

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-Figure 9 As shown, the present invention includes a drill template 4, one side of the drill template 4 is fixed with a circumferential positioning plate 1, and the drill template 4 is a cylindrical disk, and the crankshaft fixing hole K is processed in the middle part of the drill template 4, The fixed hole K of the crankshaft is matched with the size of the journal at the end of the crankshaft, and a set of drill sleeve installation holes are processed at the position concentric with the fixed hole K of the crankshaft. The drill sleeve 3 is installed in the installation hole of the drill sleeve, and the inner hole of the drill sleeve 3 Cooperate with the drill bit; the other side of the drill template 4 is provided with a clamping mechanism installation hole, the upper side of the clamping mechanism installation hole is equipped with a positioning sleeve 5, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com