Magnetron sputtering apparatus

A magnetron sputtering device and magnetron sputtering technology, applied in sputtering plating, ion implantation plating, coating, etc., can solve the problems of large-scale processing chambers, which cannot be fully solved, and have not received attention. Achieve the effects of suppressing the increase in replacement frequency, suppressing erosion, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

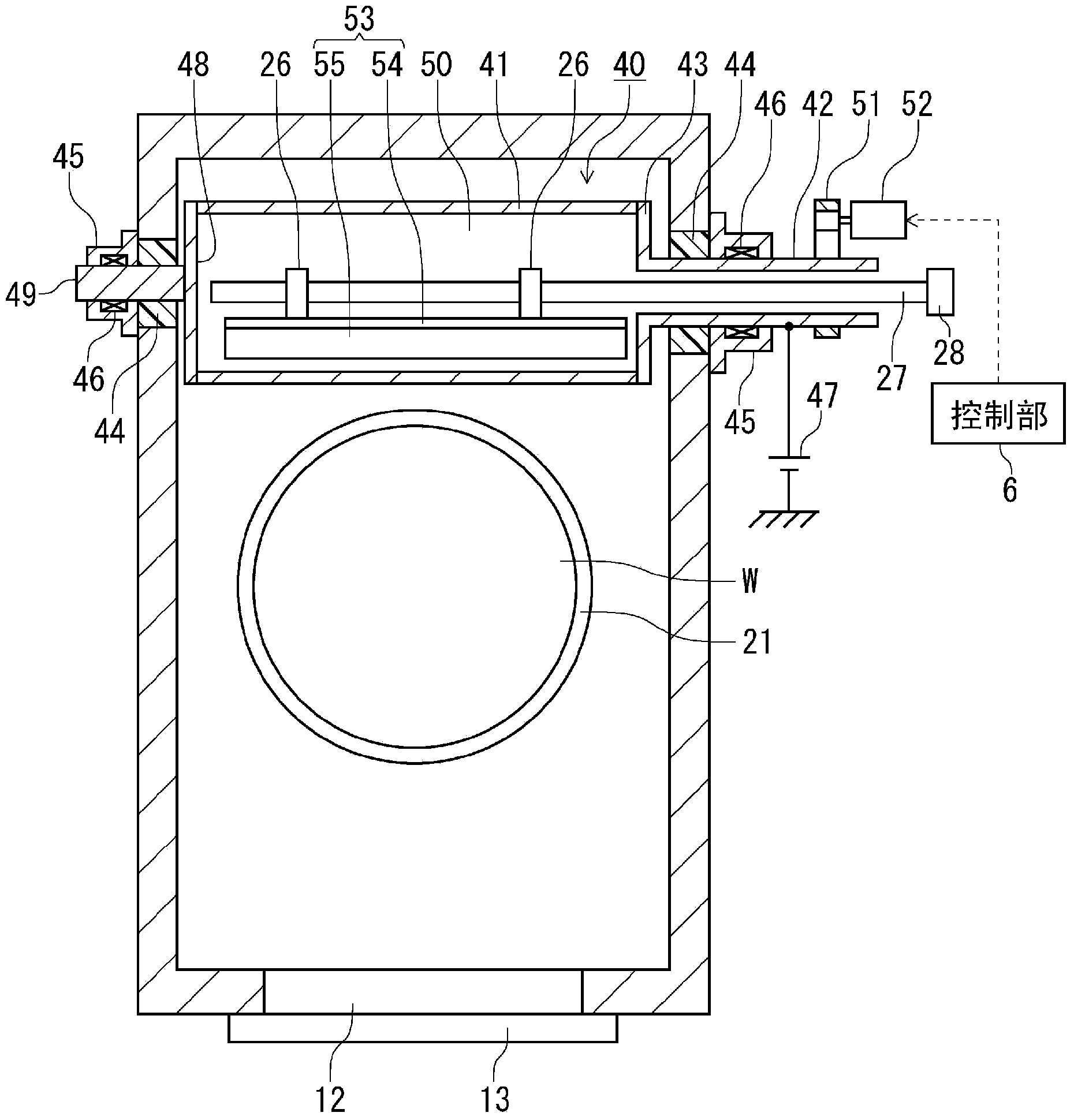

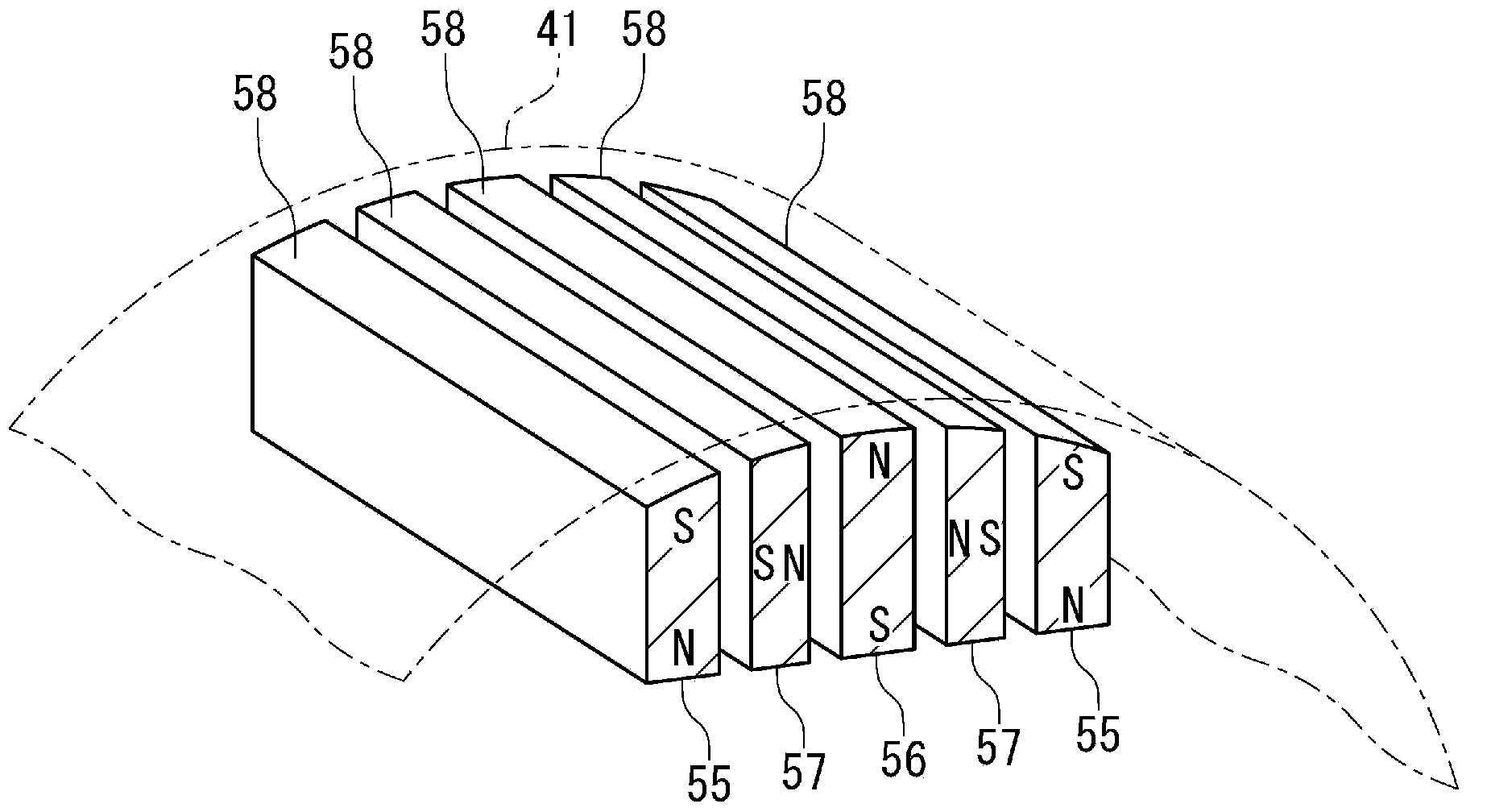

[0057] A magnetron sputtering device 1 according to an embodiment of the present invention will be described with reference to the drawings. figure 1 It is a longitudinal sectional side view of the magnetron sputtering device 1, figure 2 It is a cross-sectional plan view of the magnetron sputtering device 1 . Reference numeral 11 in the figure is a vacuum vessel made of, for example, aluminum (Al) and grounded. Reference numeral 12 in the figure is a transfer port for wafer W serving as a substrate opened on the side wall of vacuum container 11 , and is opened and closed by an opening and closing mechanism 13 .

[0058] A circular table 21 is provided in the vacuum container 11 , and a semiconductor wafer (hereinafter, simply referred to as a wafer) W as a substrate is horizontally placed on the surface of the table 21 . A wafer W having a diameter of, for example, 150 mm to 450 mm can be placed on the stage 21 . The central part of the back surface of the table 21 is con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com