A kind of preparation method of flexible electrode material

A flexible electrode and constant current technology, which is applied in battery electrodes, electrode carriers/current collectors, circuits, etc., can solve the problems of flexibility of composite materials and manganese dioxide compounding without mentioning, and achieve good reproducibility , good discharge performance and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A preparation method of flexible electrode material includes the following steps:

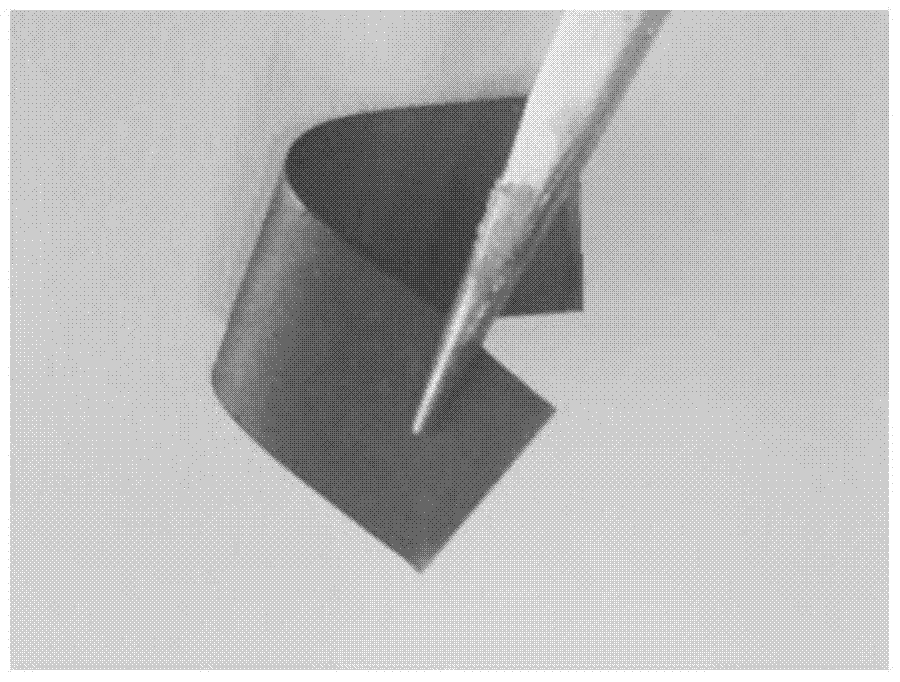

[0029] 1) Graphene film is used as electrode material, graphene and manganese salt aqueous solution is used as electrolyte, sulfuric acid is used to adjust electrolyte acidity, electrochemical deposition is adopted by galvanostatic method, and manganese dioxide and graphene are deposited on the surface of graphene film. Composite materials.

[0030] 2) The electrochemically deposited material is calcined at 300-380℃ for 1-24h, and the flexible electrode material can be obtained after calcining.

[0031] Preferably, the concentration of graphene in the electrolyte is 0.1-100 mg / ml, the concentration of sulfuric acid is 0.2-1.0 mol / L, and the concentration of manganese salt is 0.15-1.5 mol / L.

[0032] More preferably, the concentration of graphene in the electrolyte is 1-10 mg / ml, the concentration of sulfuric acid is 0.2-0.5 mol / L, and the concentration of manganese salt is 0.6-1.0 mol / L.

[0033]...

Embodiment 1

[0042] Take graphene and 100mL deionized water into a 250mL beaker, use ultrasonic and mechanical stirring to disperse for 4h, the dispersion power is 500W, and then add sulfuric acid and manganese sulfate to make 1mg / mL graphene, 0.3M sulfuric acid and 0.8M manganese sulfate solution As an electrolyte, graphene film is used as the electrode material, and electrochemical deposition is performed at a high temperature of 95°C by the constant current method, and the deposition current is 2mA / cm 2 , The deposition time is 2880s; the electrodeposited material is put into a muffle furnace and calcined at 380°C for 24h. During the calcining process, argon gas is introduced for protection, and convection is formed by blasting. After calcination, a manganese dioxide / graphene composite flexible electrode material can be obtained. The thickness of the prepared flexible electrode material is 0.1mm-0.5mm, and the mass percentage of manganese dioxide is 60%-80%.

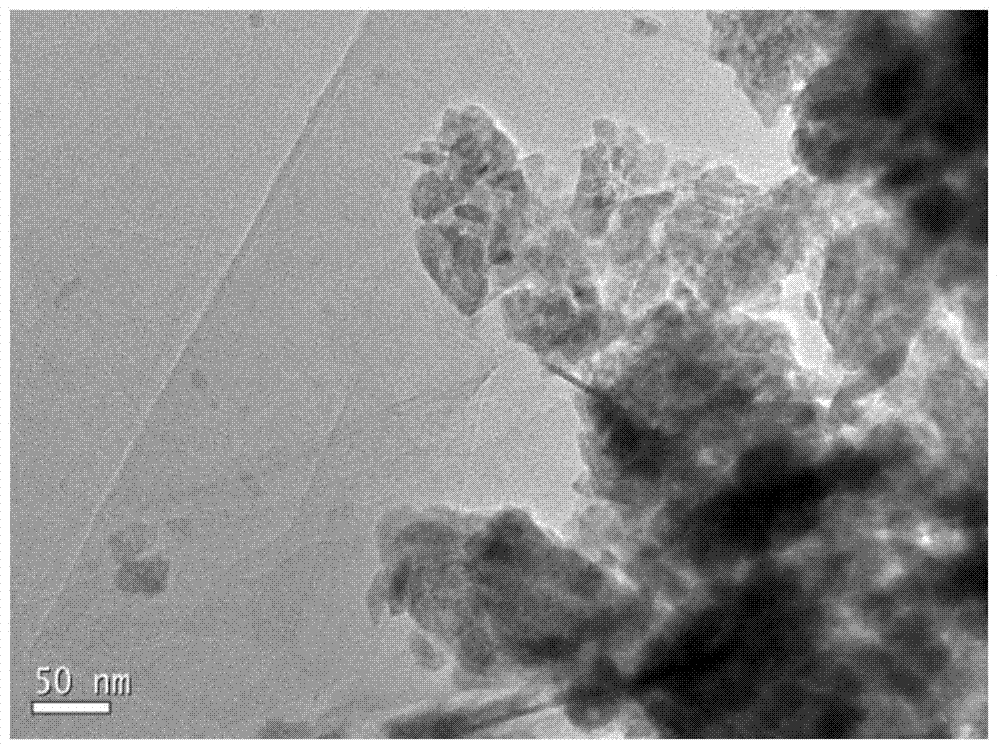

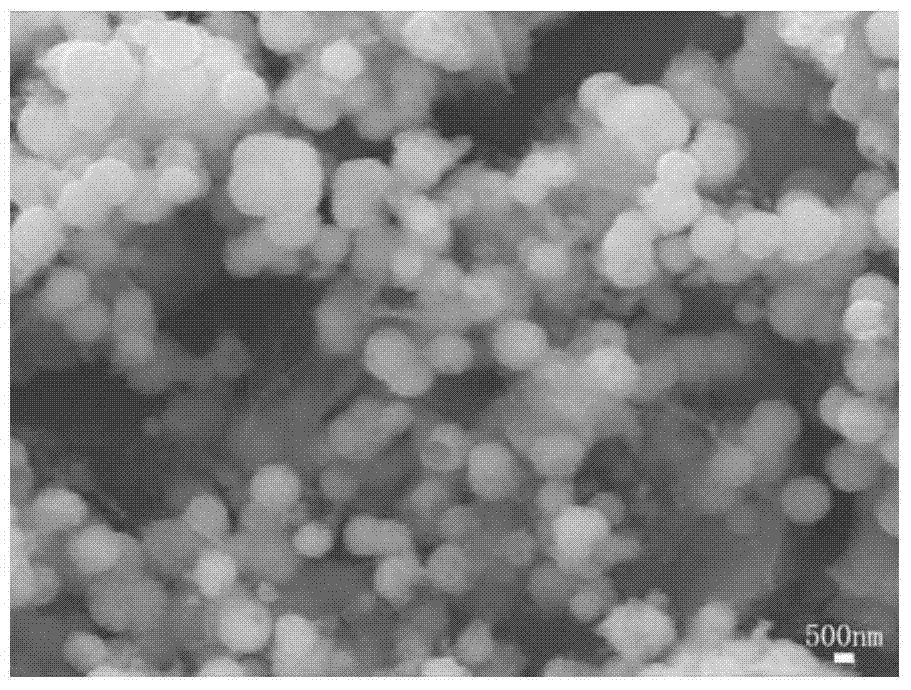

[0043] The manganese dioxide / ...

Embodiment 2

[0049] Take graphene and 100mL deionized water into a 250mL beaker, use ultrasonic and mechanical stirring to disperse for 4h, the dispersion power is 500W, and then add sulfuric acid and manganese sulfate to make 1mg / mL graphene, 0.3M sulfuric acid and 0.8M manganese sulfate solution As the electrolyte, graphene film is used as the electrode material, and the electrochemical deposition is carried out by the constant current method at a high temperature of 95℃, and the deposition current is 2mA / cm 2 , The deposition time is 2880s; put the electrodeposited material in a muffle furnace, calcined at 300 ℃ for 24h, pass argon gas for protection during the calcining process, and use blast to form convection. After calcination, the manganese dioxide / graphene composite flexible electrode material can be obtained, and the discharge curve is shown in Image 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com