Flexible nuclear radiation protecting screen

A protective screen and flexible technology, applied in the field of nuclear radiation protection, can solve the problems of poor stability, low protection efficiency, poor conformability, etc., and achieve the effect of good flexibility and excellent nuclear radiation protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

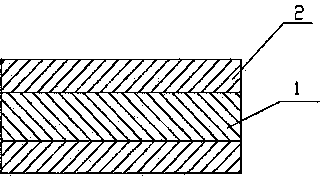

[0027] First, a flexible lead alloy fiber wire with a diameter of 0.4mm is automatically wound on the shuttle, and 16 carbon fibers with a diameter of 150D are selected to be made into a composite flexible lead alloy fiber with a diameter of 0.5mm under the action of an automatic coating machine. The composite flexible lead alloy fiber is woven on a fully automatic three-dimensional loom to form a flexible metal core layer 1 with a thickness of 1.5mm; choose a 0.5mm mesh nylon cloth 3, press polyurethane / nylon cloth / polyurethane / nylon cloth / polyurethane The mesh nylon cloth 3 and the thermoplastic polyurethane 6 are arranged in the order of, and the non-metallic coating layer 2 with a thickness of 0.75 mm is formed after hot pressing. Put the metal inner core layer 1 in the middle of two adjacent non-metal cladding layers 2, and perform secondary forging on a hot press to form a flexible nuclear radiation shield with a thickness of 3 mm. According to the requirements of use, pe...

Embodiment 2

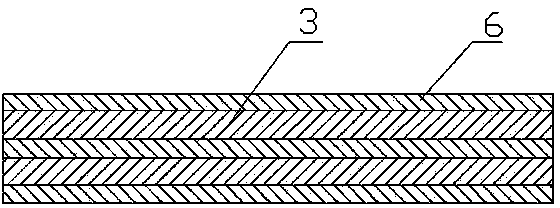

[0029] First, a flexible lead alloy fiber with a diameter of 0.4mm and a tungsten alloy fiber with a diameter of 0.04mm are mixed and wound on the shuttle, and 32 carbon fibers with a diameter of 100D are selected and made into a diameter under the action of an automatic coating machine 0.6mm composite flexible alloy fiber, then the composite flexible alloy fiber is woven on a three-dimensional loom to form a flexible metal core layer 1 with a thickness of 1.8mm. A carbon fiber cloth 4 with a thickness of 0.3 mm is selected, and a mesh carbon fiber cloth and a thermoplastic polyurethane layer 6 are arranged in the order of polyurethane / carbon fiber cloth / polyurethane, and a 0.5 mm thick non-metal coating layer 2 is formed after hot pressing. Put the metal inner core layer 1 with a thickness of 1.8mm into the middle of two adjacent non-metal cladding layers 2, and perform secondary forging on the hot press to form a flexible nuclear radiation shield with a thickness of 4mm. It i...

Embodiment 3

[0031] First, a flexible lead alloy fiber with a diameter of 0.4mm and a tantalum alloy fiber with a diameter of 0.03mm are mixed and wound on the shuttle, and 32 carbon fibers with a diameter of 100D are selected and made into a diameter under the action of an automatic coating machine The composite flexible alloy fiber is 0.6mm, and then the composite flexible alloy fiber is woven on a three-dimensional loom to form a flexible metal core layer 1 with a thickness of 1.8mm. A carbon fiber cloth 4 with a thickness of 0.3 mm is selected, and the meshed carbon fiber cloth and polyvinyl chloride 7 are arranged in the order of PVC / carbon fiber cloth / polyvinyl chloride, and a non-metallic coating 2 with a thickness of 0.5 mm is formed after hot pressing. Put the metal inner core layer 1 in the middle of two adjacent non-metal cladding layers 2 and perform secondary forging on a hot press to form a flexible nuclear radiation shield with a thickness of 2.8 mm. According to the requirem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com