Electrode bar production method, electrode bar and fusion splicer comprising electrode bar

A production method and electrode rod technology, which is applied in the field of optical fiber fusion, can solve the problems of poor discharge effect of electrode rods, and achieve the effects of less replacement, less corrosion, and less difficult operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

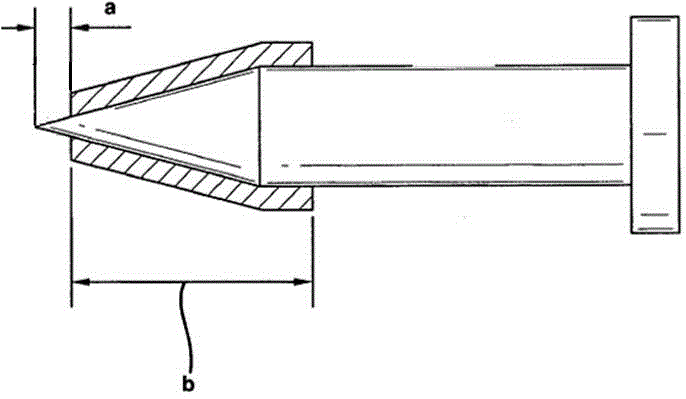

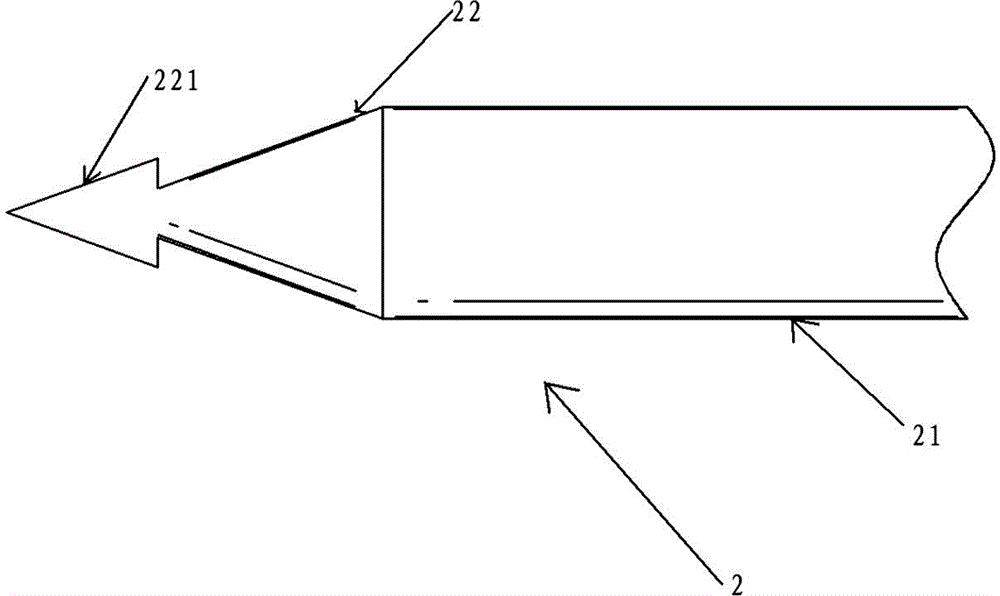

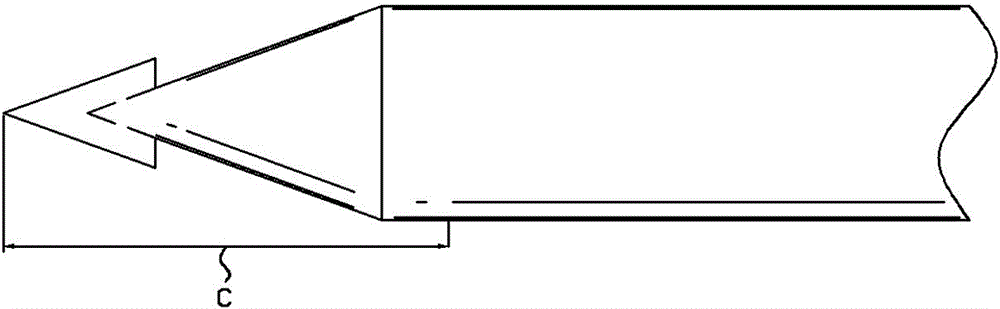

[0026] Due to the adhesion of glass fibers to the rear end of the existing electrode rods, the discharge effect will be affected after long-term use, resulting in the need to replace the electrode rods, resulting in frequent replacement of the electrode rods. In order to solve this problem, the Chinese patent application "201110000507.3" discloses "an electrode rod with an insulating coating and an optical fiber fusion splicer including the electrode rod". High-temperature insulating coating. The high-temperature insulating coating is generally made of insulating materials such as ceramics or silicon carbide. The high-temperature insulating coating is not coated on the top of the rod tip (discharge end), so that the tip of the rod tip (discharge end) is within the allowable conduction state. Although the above-mentioned technical solution solves the problem of glass fiber sticking on the electrode rod to a certain extent, its process has the following defects: the bonding mode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com