Cylindrical compression spring parameter testing method

A compression spring and parameter testing technology, which is applied in the detection field, can solve the problems of low test efficiency and low test accuracy of cylindrical compression spring parameters, and achieve the effect of realizing test automation, improving test accuracy, and avoiding inconsistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

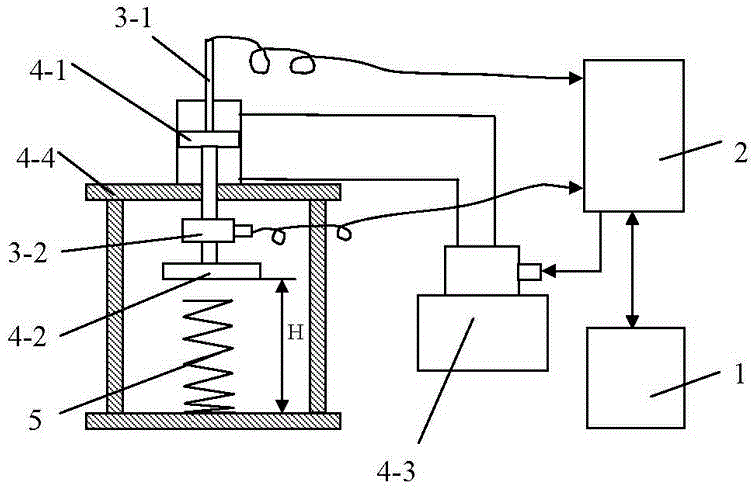

[0027] The data acquisition software of the displacement measurement of spring and the load in the method of the present invention uses the supporting data acquisition driver software NIDaqmx of the NI PCI-6221 multifunctional data acquisition card of National Instruments Company. Such as figure 1 Shown, be the physical test model that the present invention needs to set up: comprise the oil cylinder 4-1 that frame 4-4 is arranged on the frame 4-4, have piston rod through in oil cylinder 4-1, the lower end of piston rod stretches into The frame 4-4 is connected with a pressure plate 4-2, a force sensor 3-2 is set above the pressure plate 4-2, and the measured spring 5 is placed under the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com