Fuel cell internal temperature-current density synchronous measurement sensor

A current density, fuel cell technology, applied in current density measurement, thermometers, thermometers with directly sensitive electrical/magnetic components, etc., can solve the problems of fuel cell performance degradation, complex fabrication, and difficulty in combining temperature measurements , to achieve the effect of reducing performance reduction, convenient production and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

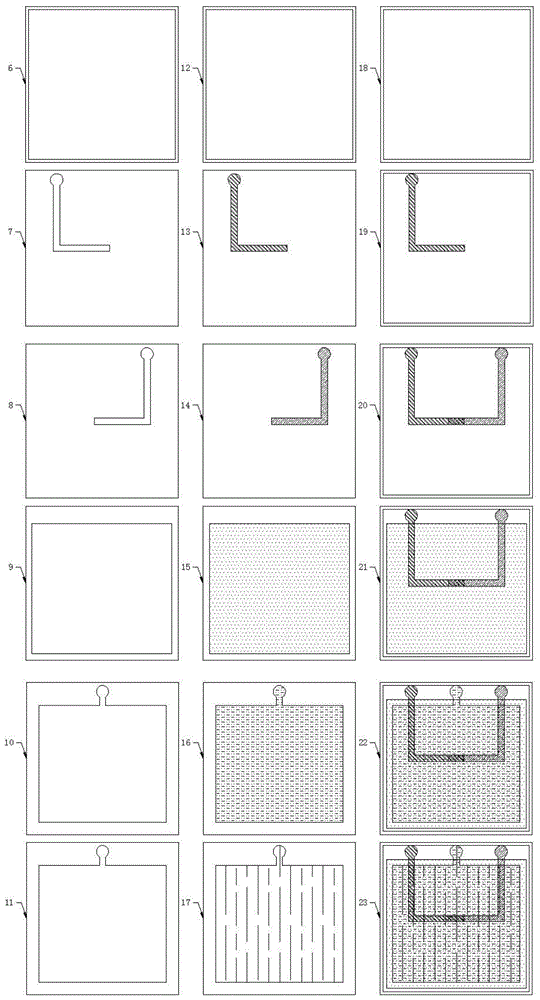

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

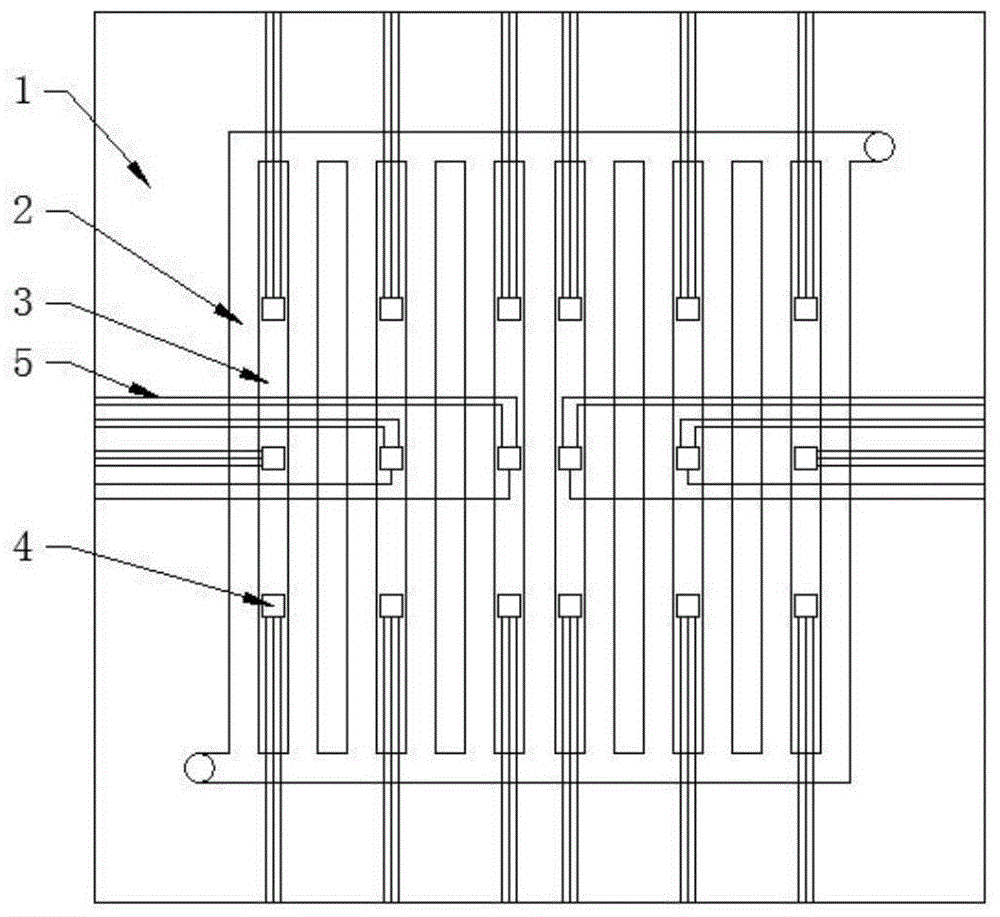

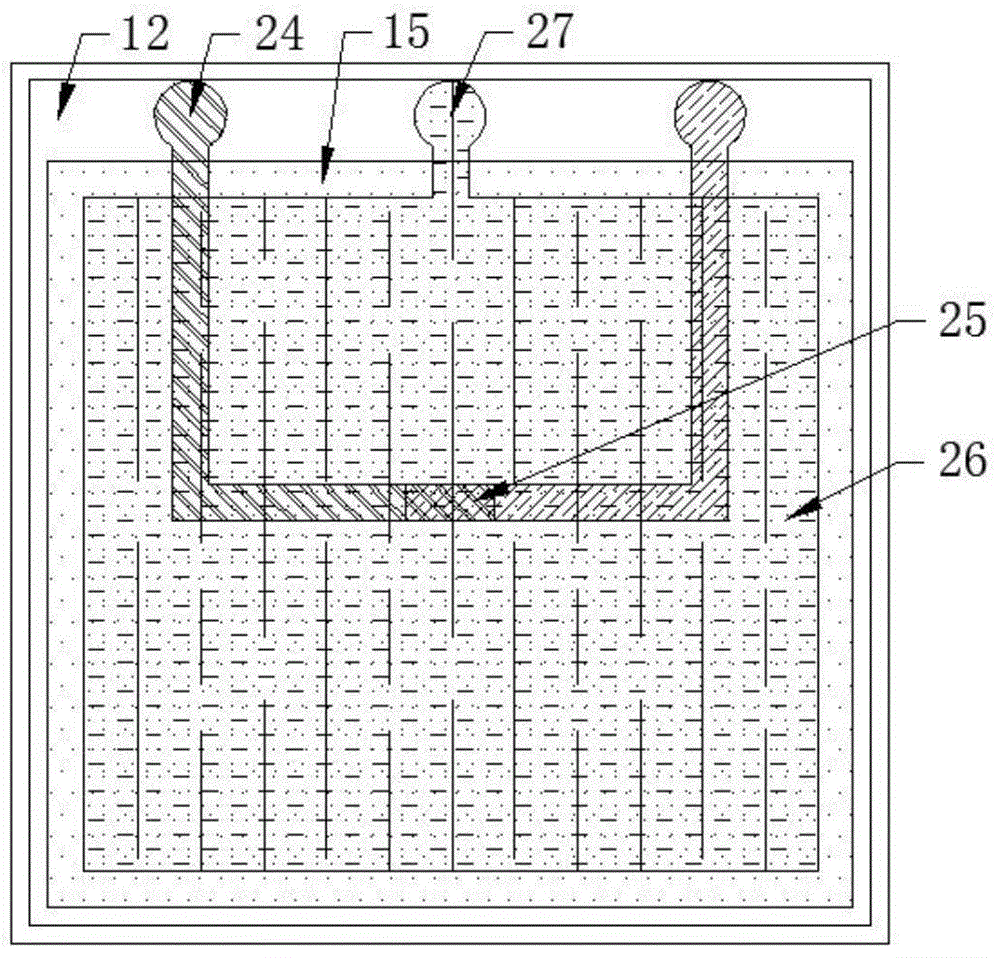

[0035] refer to figure 1 As shown, the fuel cell internal temperature-current density joint measurement sensor of the present invention includes a fuel cell flow field plate 1, a temperature-current density joint measurement sensor 4, a lead wire 5, and the temperature-current density joint measurement sensor 4 is arranged on the fuel cell flow field. On the ridge 3 between two adjacent flow channels 2 of the field plate 1, one end of the lead wire 5 is connected to the wiring lead-out end of the temperature-current density joint measurement sensor 4, and the other end extends to the edge of the flow field plate for transmitting temperature-current density. The electrical signal generated by the current density joint measurement sensor; when the fuel cell is assembled, the surface of the fuel cell flow field plate 1 where the temperature-current density joint measurement...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com