Drying process for insoluble sulfur and process equipment for insoluble sulfur

A drying process and soluble technology, which is applied in the field of insoluble sulfur drying process and its process equipment, can solve the problems of not improving the drying process, etc., and achieve the effects of favorable condensation recovery, fast heat transfer speed, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

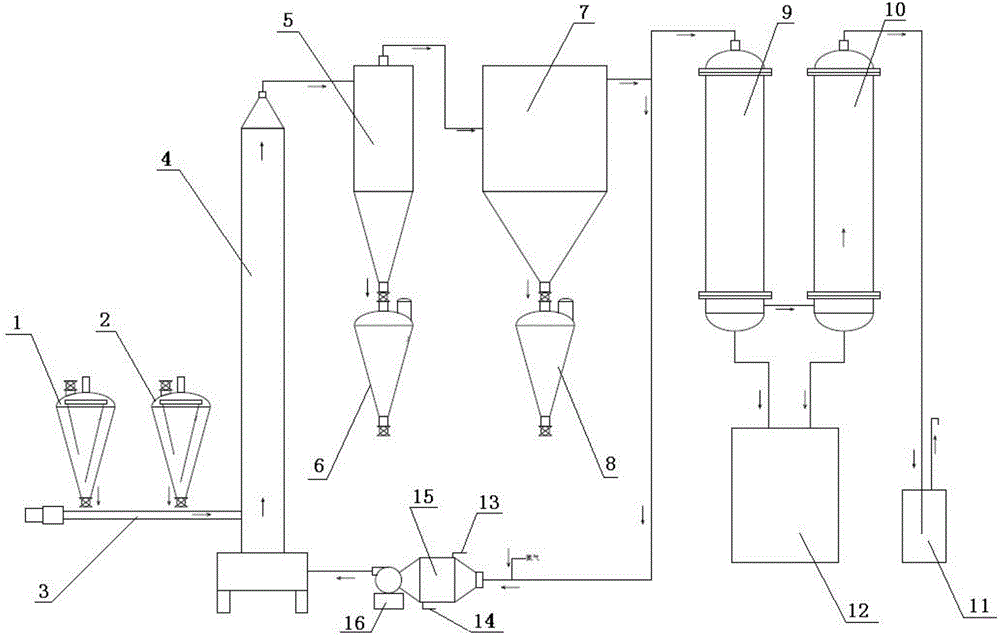

[0033] A process equipment for insoluble sulfur drying, including the first mixing silo 1 and the second mixing silo 2, feeder 3, drying tower 4, cyclone collector 5, first nitrogen replacement silo 6, bag type Dust collector 7 , second nitrogen replacement bin 8 , condenser 9 , deep cooler 10 , liquid collection tank 12 , water seal tank 13 , heat exchanger 15 and fan 16 .

[0034] Wherein, the first mixing silo 1 and the second mixing silo 2 communicate with the feeder 3 respectively; the feeder 3 communicates with the lower part of the drying tower 4; the top of the drying tower 4 communicates with the cyclone collector 5; the cyclone collector The top of the bag filter 7 is connected to the bag filter 7, and the lower end of the cyclone collector 5 is connected to the first nitrogen replacement bin 6; the bag filter 7 is connected to the condenser 9, and the lower end of the bag filter 7 is connected to the second nitrogen replacement bin 8; the condenser 9 communicates wi...

Embodiment 2

[0036] A drying process for insoluble sulfur, the process is as follows:

[0037] Start the process equipment, charge carbon disulfide gas into the drying tower 4 and make the hot air circulation system greater than the dew point temperature, start the heat exchanger 15 and the circulation fan 16, and keep the air volume at 1000m 3 / h, control the wind temperature at 80-85 degrees Celsius. 150kg of insoluble sulfur powder containing 30% carbon disulfide in the first mixing silo 1 and the second mixing silo 2 are evenly sent into the drying tower 4 through the closed feeder 3, and the mixing temperature at the top of the drying tower is controlled at 50 by controlling the feeding amount. -55 degrees Celsius.

[0038] After the insoluble sulfur powder material is delivered, close the heat exchanger 15 and the fan 16, respectively fill the first nitrogen replacement bin 6 below the collector 5 and the second nitrogen replacement bin 8 below the dust collector 7 with nitrogen and...

Embodiment 3

[0041] A kind of drying process of insoluble sulfur, technological process is as described in embodiment 2, and its difference is, the temperature of the carbon disulfide gas hot blast that controls to pass into drying tower 4 is at 70-75 degree Celsius, and wind speed is 2.5m / s. Obtain insoluble sulfur powder 104.8kg at last, reclaim carbon disulfide liquid 43.65kg in the liquid collecting tank 12, solvent recovery rate reaches more than 96%, insoluble sulfur powder heating loss is 0.24%, meets the requirement that qualified product is less than 0.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com