Channel type cooling structure of flame tube in combustion chamber of gas turbine

A cooling structure, gas turbine technology, applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems of uneven temperature distribution on the wall surface of the flame tube, easy to cause large thermal stress, uneven heat load, etc., to improve cooling Efficiency, improved flow conditions, improved uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The principle, structure and specific implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

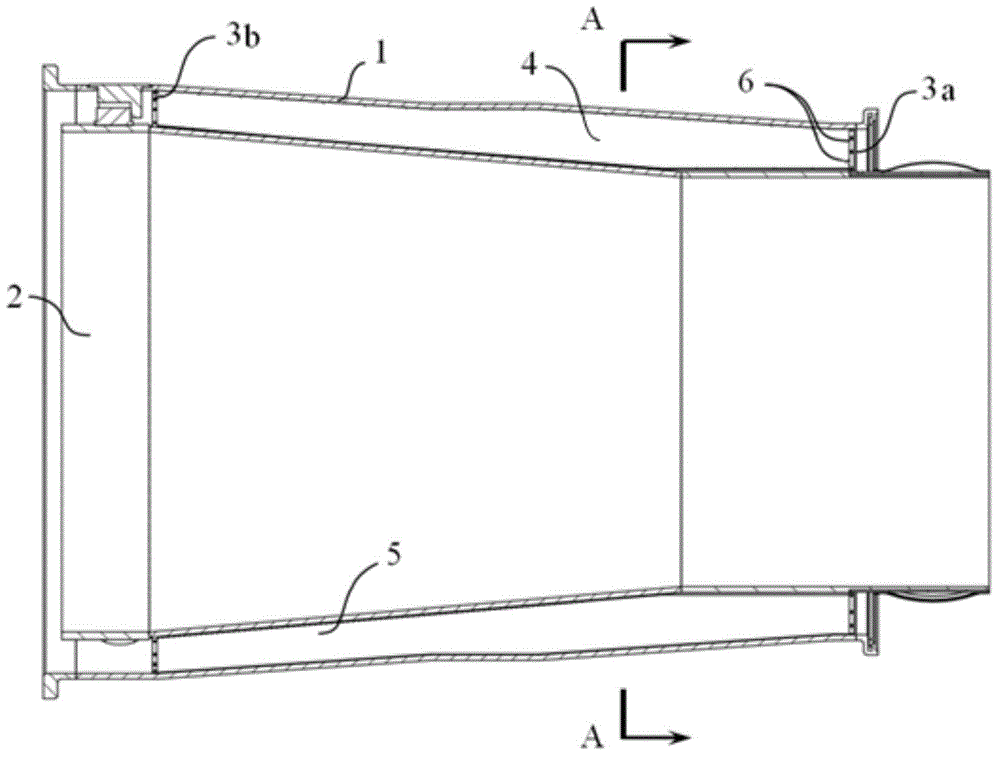

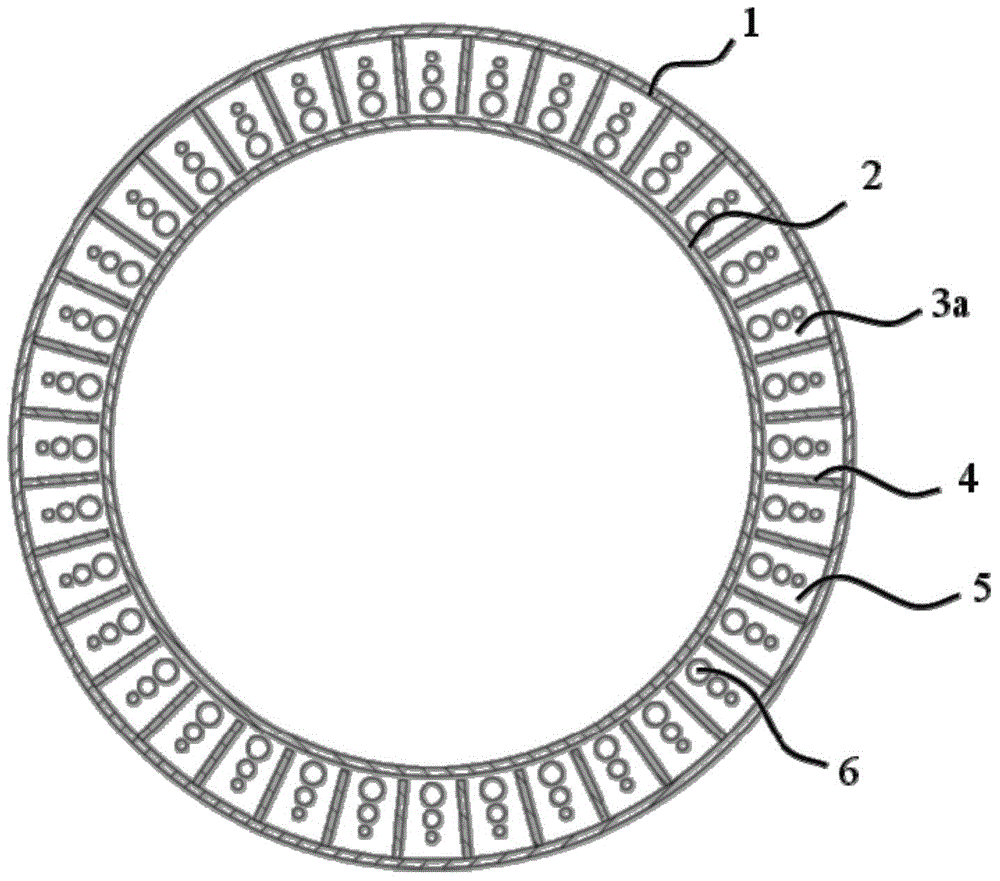

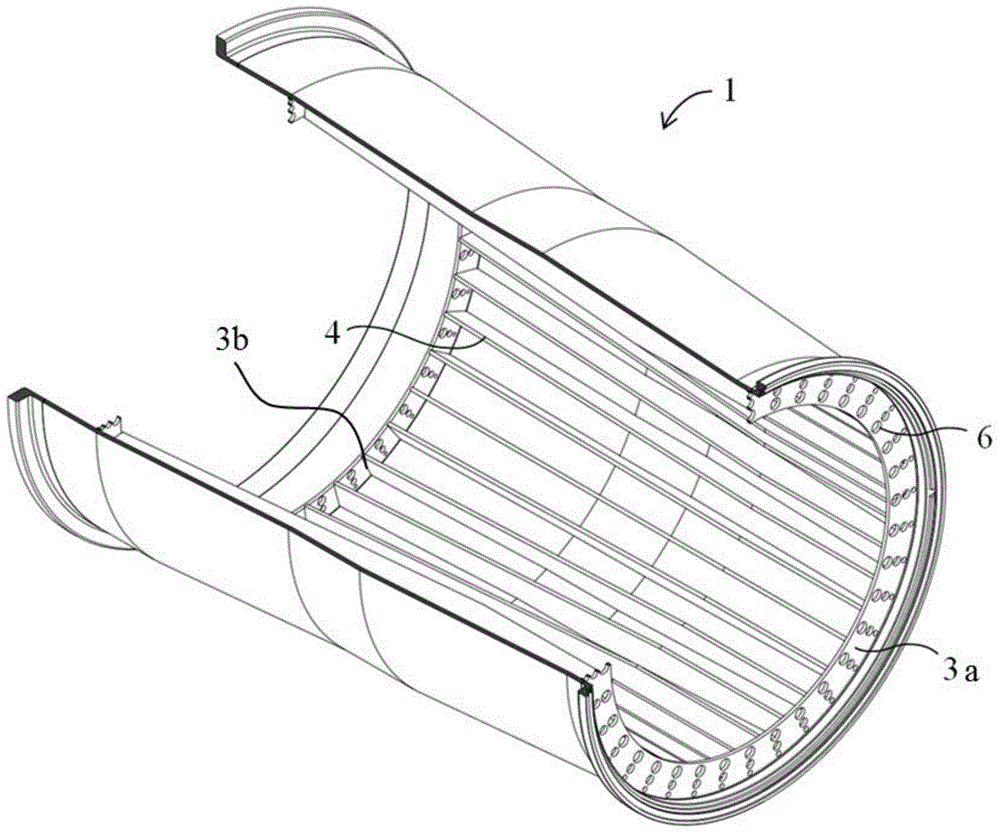

[0019] figure 1 It is a cross-sectional view of a gas turbine combustor flame tube with a channel cooling structure. As shown in the figure, a flow guide bushing 1 is arranged outside the flame tube 2, and the gap between the flow guide bush 1 and the flame tube 2 is An annular return air channel 5 is formed. The cooling structure is arranged in the annular return air passage 5, and the structure includes a plurality of baffles 4 arranged axially along the flame tube 2, a front end cover 3a and a rear end cover 3b; the baffles 4 are fixed on the guide bushing 1, the front end cover plate 3a is fixed on the inner wall of the guide bush 1 at the entrance of the annular return air channel 5, and the rear end cover plate 3b is fixed on the inner wall of the guide bush 1 at the outlet of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com