Compressor apparatus with bleed slot including turning vanes

A discharge tank and compressor technology, applied in the field of compressors, can solve problems such as unfavorable structure and thermomechanical effects of compressors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

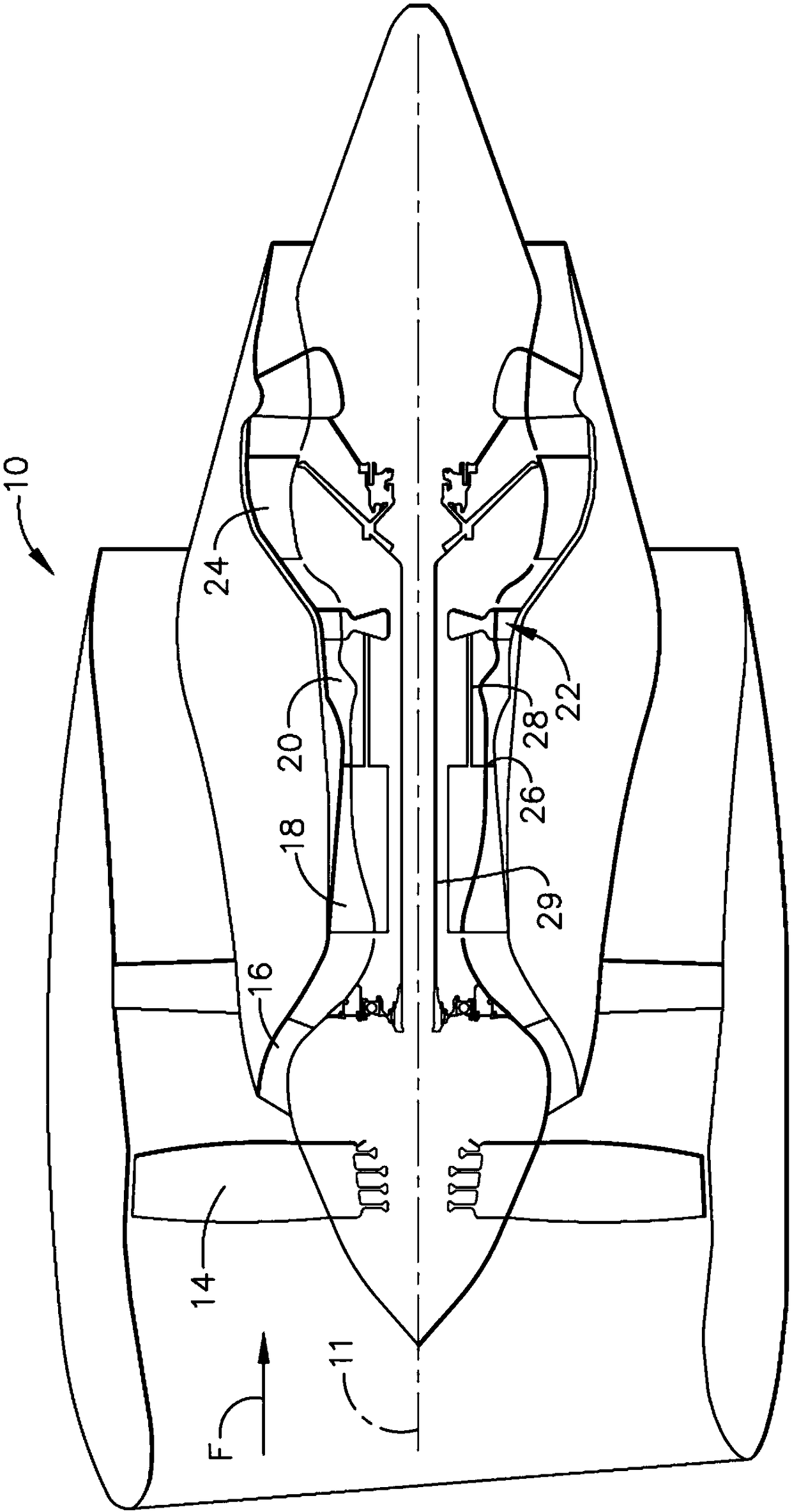

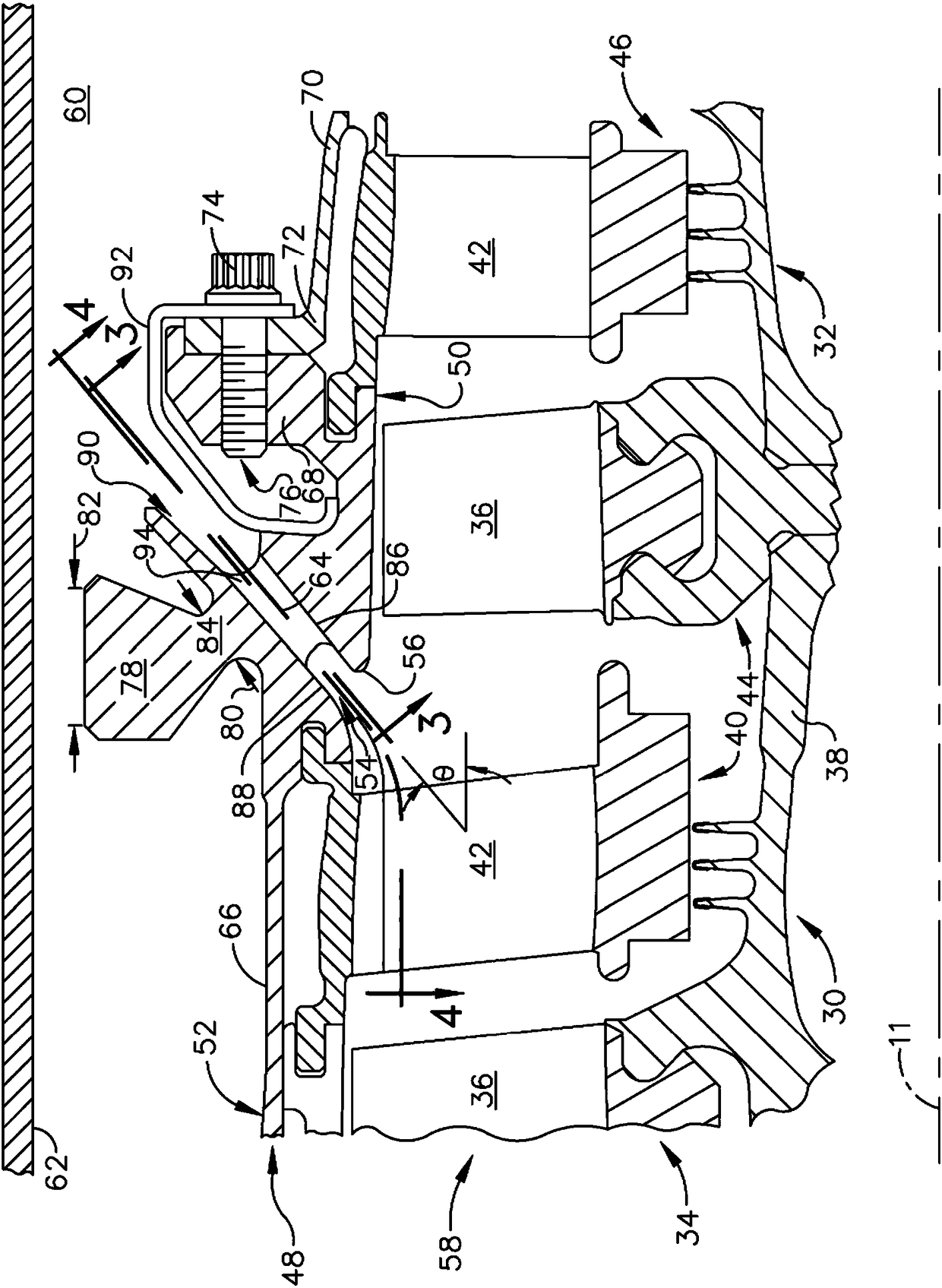

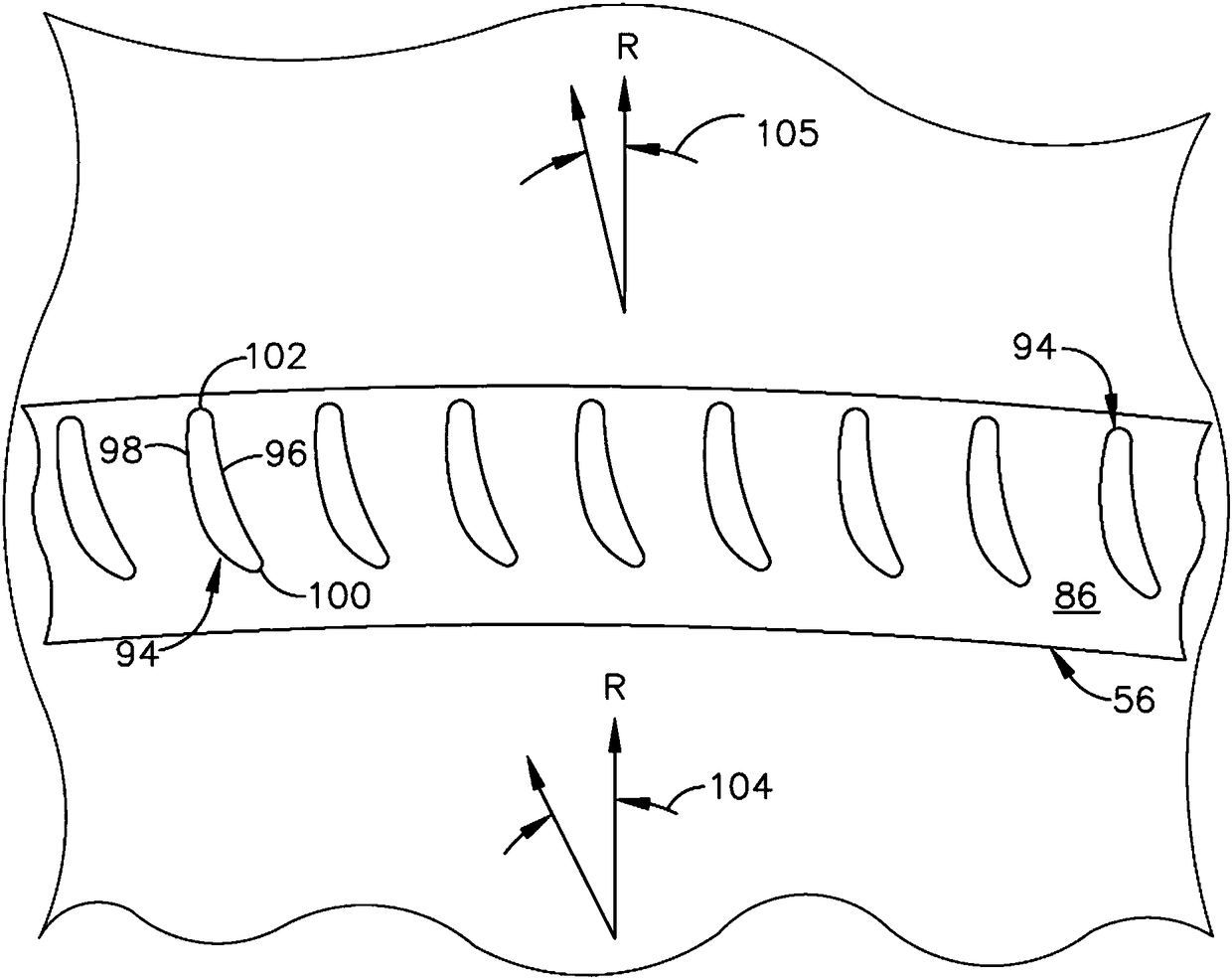

[0036] With reference to the drawings in which like reference numerals denote like elements in the various views, figure 1 An exemplary gas turbine engine 10 is depicted. Although the illustrated example is a high-bypass turbofan engine, the principles of the invention are applicable to other types of engines, such as low-bypass turbofans, turbojets, turboprops, etc., and with any number of compressors Turbine engine with turbine shaft. Engine 10 has a longitudinal centerline or axis 11 .

[0037] It should be noted that, as used in this specification, the terms "axial" and "longitudinal" both refer to directions parallel to the centerline axis 11, while "radial" refers to directions perpendicular to the axial direction, and "tangential " or "circumferential" refers to directions perpendicular to each other in the axial and radial directions. As used in this specification, the term "forward" or "front" refers to a position relatively upstream in the airflow through or aroun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com