Bilinear asymmetric toothed medium-pressure gear pump

An asymmetric gear pump technology, applied in the direction of pumps, rotary piston pumps, rotary piston machinery, etc., can solve the problems that cannot meet the needs of large displacement gear pumps, cannot realize medium pressure gear pumps, and increase noise. Achieve the effects of novel structure, low noise and increased pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

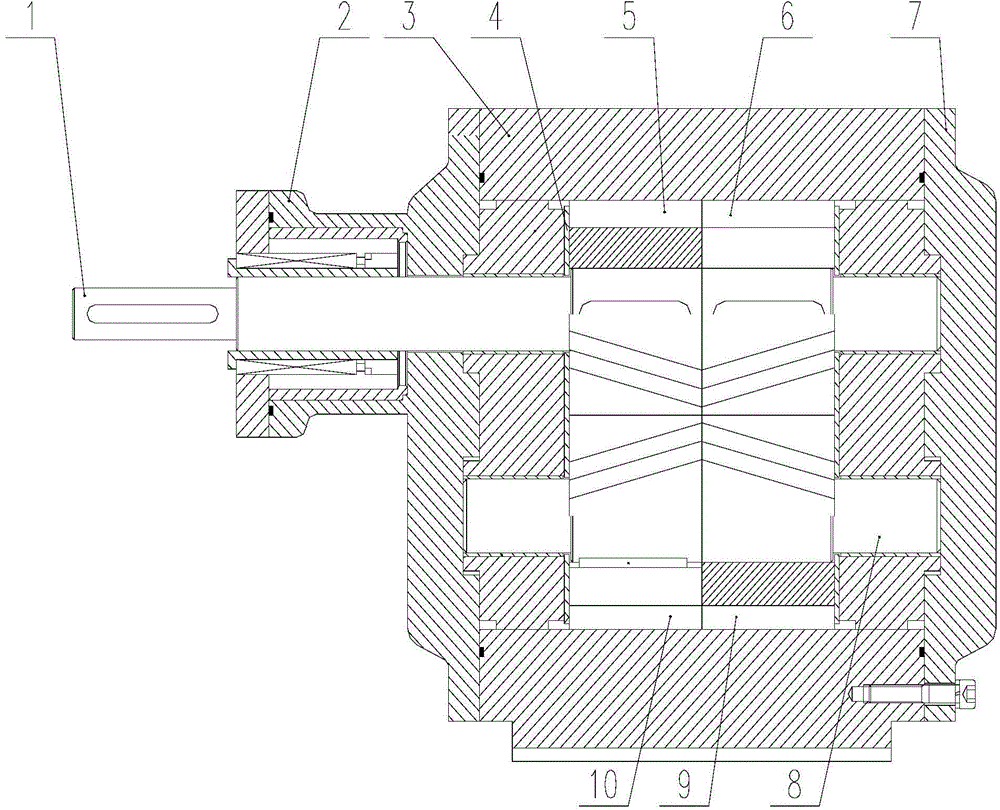

[0020] The specific embodiment of the present invention is shown in the accompanying drawings, a two-line asymmetric tooth profile medium pressure gear pump, including a driving shaft 1, a front end cover 2, a pump body 3, a floating pressure side plate 4, a rear end cover 7 and a driven shaft 8. The front end cover 2 and the rear end cover 7 are respectively installed on the front and rear ends of the pump body 3, and the driving shaft is installed on the pump body 3 through two floating pressure side plates 4, and protrudes through the shaft hole on the front end cover 2 Outside the pump; it is characterized in that the driving shaft 1 between the two floating pressure side plates 4 is equipped with a double-line asymmetrical gear I5 and a double-line asymmetrical gear II6; the floating pressure side plate 4 is also equipped with a driven Shaft 8, on driven shaft 8, bilinear asymmetrical gear III9 and bilinear asymmetrical gear IV10 are housed.

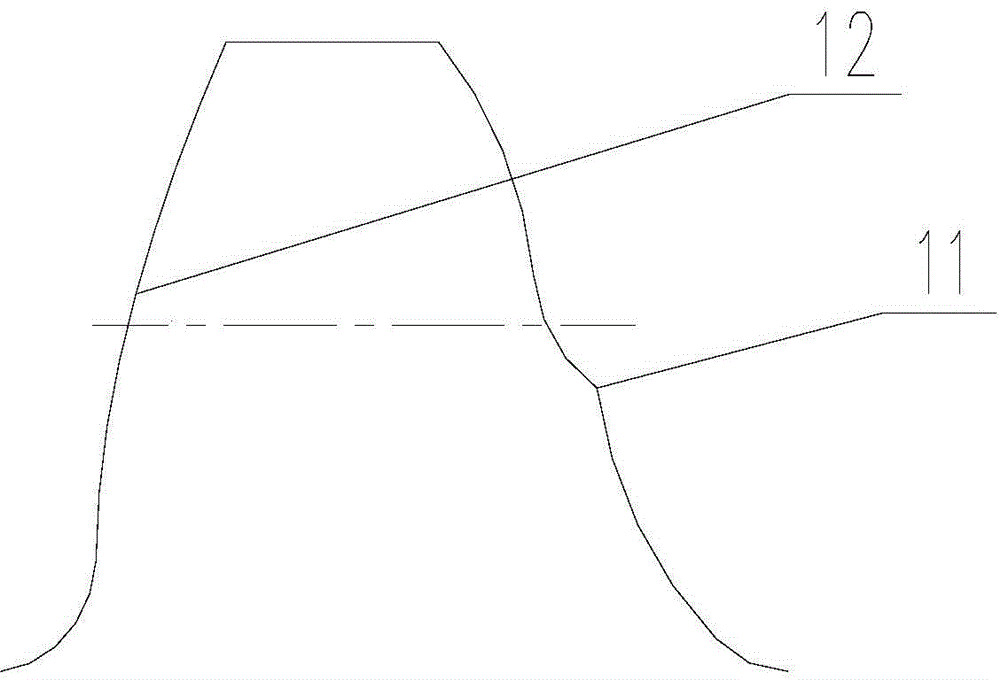

[0021] The working side 11 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com