Rapid stripping device, stripping equipment and stripping method for metal layer of cathode plate

A stripping device and cathode plate technology, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems that there is no public solution to technical problems, can not be solved, and achieve the effect of improving reliability, rapid stripping, and reducing failure factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

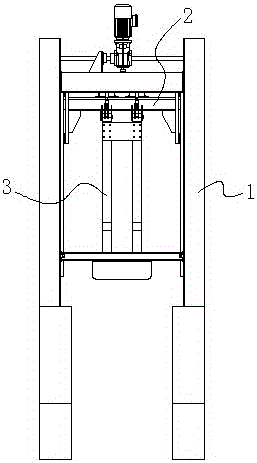

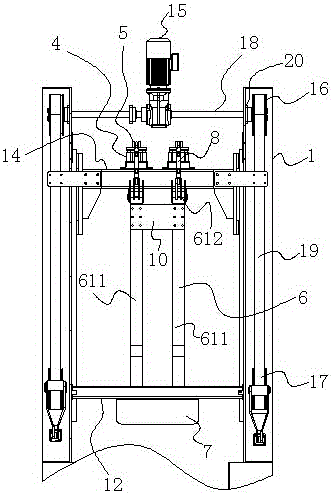

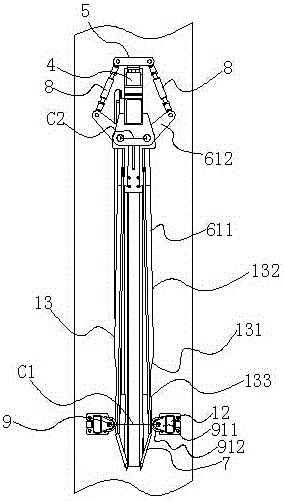

[0041] Embodiment 1: as Figure 1 to Figure 4 As shown, a quick peeling device for the metal layer of the cathode plate includes a frame 1, a lifting mechanism 2 arranged on the top of the frame 1 and a peeling mechanism 3 arranged on the lifting mechanism 2, the peeling The mechanism 3 includes a cylinder energy storage unit 4 arranged on the lifting mechanism 2, the gas of the cylinder energy storage unit is in a pre-compressed state, connected with the cylinder energy storage unit 4 and can store energy in the cylinder Under the action of the unit, the lifting fork seat 5 reciprocating up and down, the stripping knife opening and closing frame 6 on both sides, and the stripping knife 7 arranged on the stripping knife opening and closing frame 6; the stripping knife opening and closing frame 6 includes The long arm 611 and the short arm 612 with one end obliquely fixedly connected to one end of the long arm 611 are hinged to the lifting mechanism 2 at the junction of the lon...

Embodiment 2

[0060] Embodiment 2: as Figure 9 As shown, compared with Embodiment 1, the difference of this embodiment is that the peeling mechanism is arranged on the lifting mechanism as a compression spring energy storage unit, and the compression spring energy storage unit includes a The sleeve 26 on the upper part of the lifting beam 14, the compression spring 27 arranged inside the sleeve 26 and the piston 28 with a rod; the piston 28 is in contact with the compression spring 27, and the rod of the piston 28 passes through One end of the sleeve 26 is connected with the lifting fork 5 . When the lifting fork 5 moves downward, the compression spring 27 is compressed, and the energy is stored through the compression spring 27; when the lifting fork 5 moves upward, the compression spring 27 is reset and rebounded, and the energy is released through the lifting fork 5 Going out, such a cycle forms a process in which the compression spring energy storage unit repeatedly stores energy and ...

Embodiment 3

[0061] Embodiment 3: as Figure 10 to Figure 12 As shown, compared with Embodiment 1 or Embodiment 2, the difference is that a cathode plate locking device 29 is also provided at the bottom of the frame 1 of the quick stripping device, which includes locking plates 291 on both sides, The locking plate support bar 292 on both sides, the locking plate cylinder or the locking plate hydraulic cylinder 293 on both sides; one end of the locking plate support bar 292 on each side is hinged with the bottom of the frame 1, and the other end is connected with each side The outer surface of locking plate 291 is hinged, and one end of locking plate cylinder or locking plate hydraulic cylinder 293 on each side is hinged with the bottom of the frame 1, and its other end is hinged with the outer surface of each side locking plate 291, so The locking plates 291 on both sides are relatively symmetrically arranged, and the inner surfaces of the locking plates 291 on both sides include two strai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com