Novel double-silver LOW-E coated glass

A coated glass, a new type of technology, applied in glass/slag layered products, chemical instruments and methods, layered products, etc., can solve the problems of film release, easy slag removal, poor film adhesion, etc., and achieve optical performance. Good, not easy to drop slag, strong adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

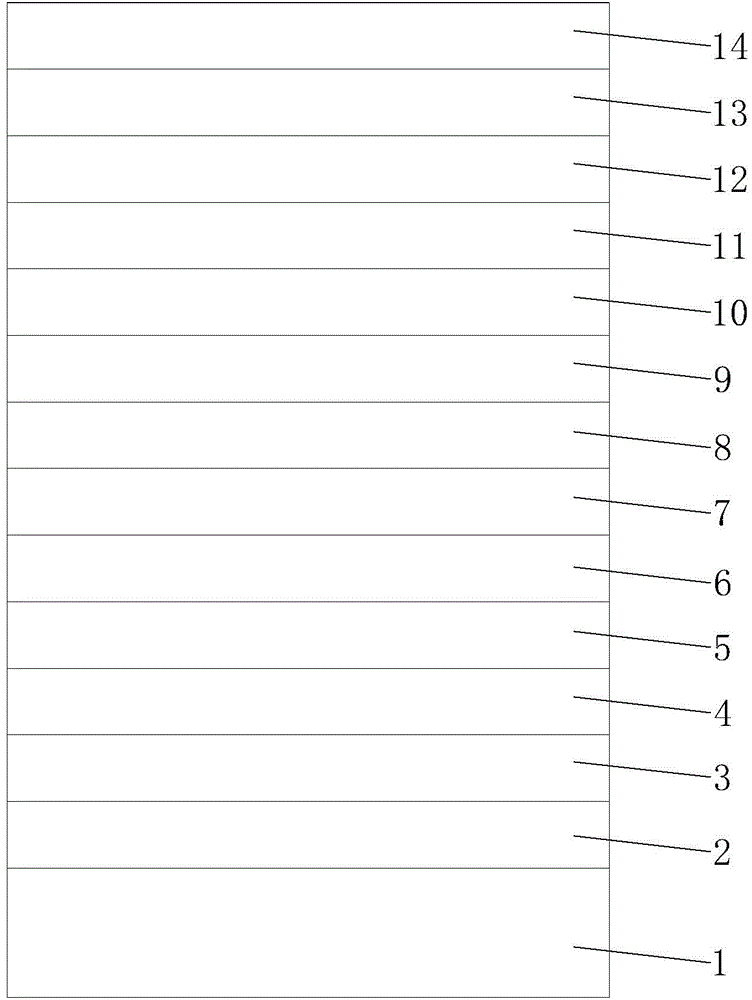

[0015] As shown in the figure, a new type of double-silver LOW-E coated glass includes a glass substrate 1, and the upper surface of the glass substrate 1 is sequentially provided with Si x N y Base film layer 2, the first TiO x Film layer 3, first AZO barrier layer 4, first Ag layer 5, first NiCr barrier layer 6, second AZO barrier layer 7, second TiO x Film layer 8, third AZO barrier layer 9, second Ag layer 10, second NiCr barrier layer 11, fourth AZO barrier layer 12, third TiO x Film layer 13, and Si x N y Top film layer 14.

[0016] Further, the Si x N y The thickness of the base film layer 2 is 10-15 nm. It adopts the magnetron sputtering coating process, and uses AC intermediate frequency power supply, argon as the sputtering gas, and nitrogen as the reactive gas to sputter the silicon-aluminum target (silicon-aluminum mass percentage 92:8), where the argon-nitrogen ratio is ( 400SCCM~420SCCM): (450SCCM~500SCCM), the ratio of argon and nitrogen is the core of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com