A high-efficiency industrial wastewater terminal water arsenic removal equipment

A high-efficiency technology for industrial wastewater, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. The effect of improving recycling rate, increasing stroke and time, and increasing effective capture rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

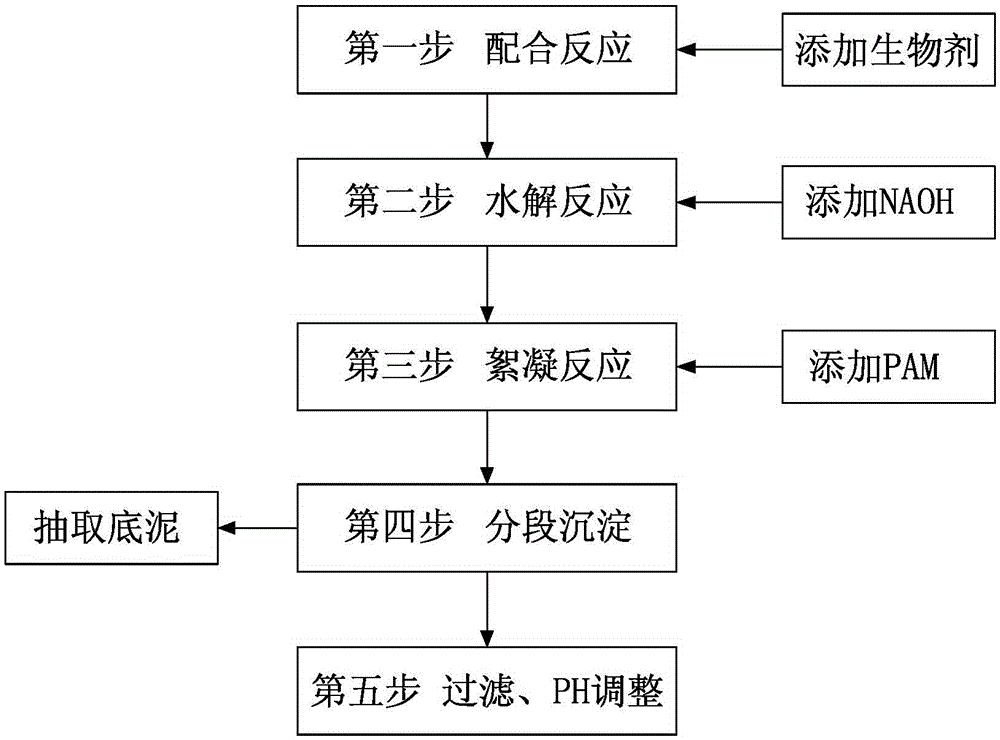

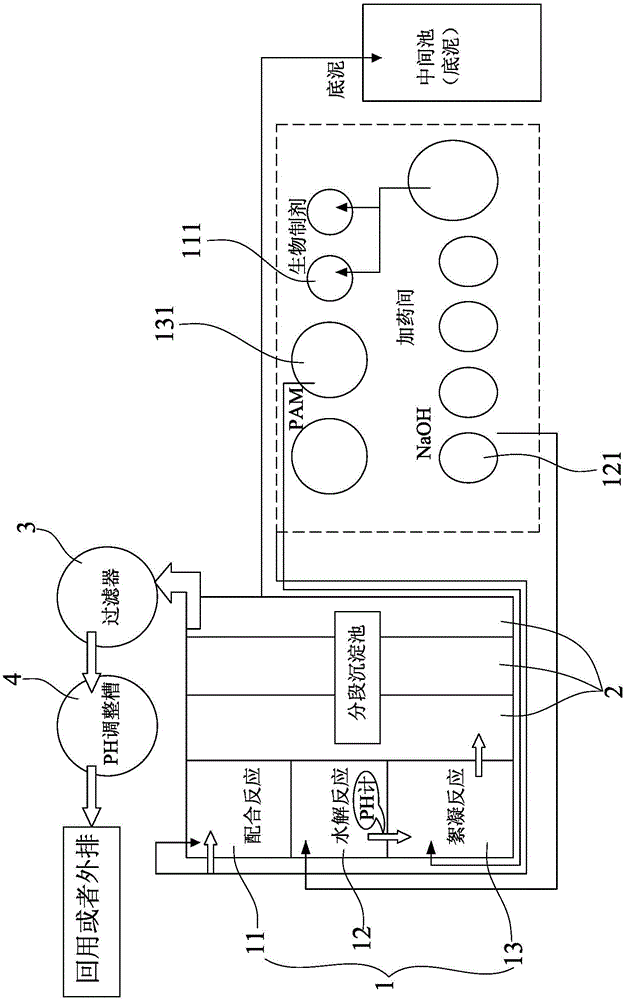

[0016] Combine below figure 1 , figure 2 The present invention is described further:

[0017] In the present invention, the S-002 water treatment agent used is a special agent for heavy metal wastewater treatment jointly developed and produced by Central South University, Changsha Sainz Environmental Protection Technology Co., Ltd.

[0018] It is a new type of environmental protection product for advanced treatment and recycling of wastewater. Its biological preparations are designed with metabolites of complex functional flora based on Thiobacillus and other compounds. Through group grafting technology, biological preparations containing a large number of functional groups such as hydroxyl, sulfhydryl, carboxyl, and amino groups have been prepared. The heavy metal wastewater is smelted through the synergistic coordination of multiple groups of biological agents to form stable heavy metal complexes, adjust the pH value with alkali, and coordinate decalcification; due to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com