Method for producing high-quality enriched superphosphate as byproduct in production of feed grade calcium hydrophosphate

A technology rich in calcium superphosphate and calcium hydrogen phosphate, applied in the direction of calcium superphosphate, chemical instruments and methods, phosphate fertilizer, etc., can solve the backlog of fertilizer grade calcium hydrogen phosphate, low price, and affect the economic benefits of feed grade calcium hydrogen phosphate enterprises, etc. problem, to achieve the effect of realizing economic benefits, maximizing, and good reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

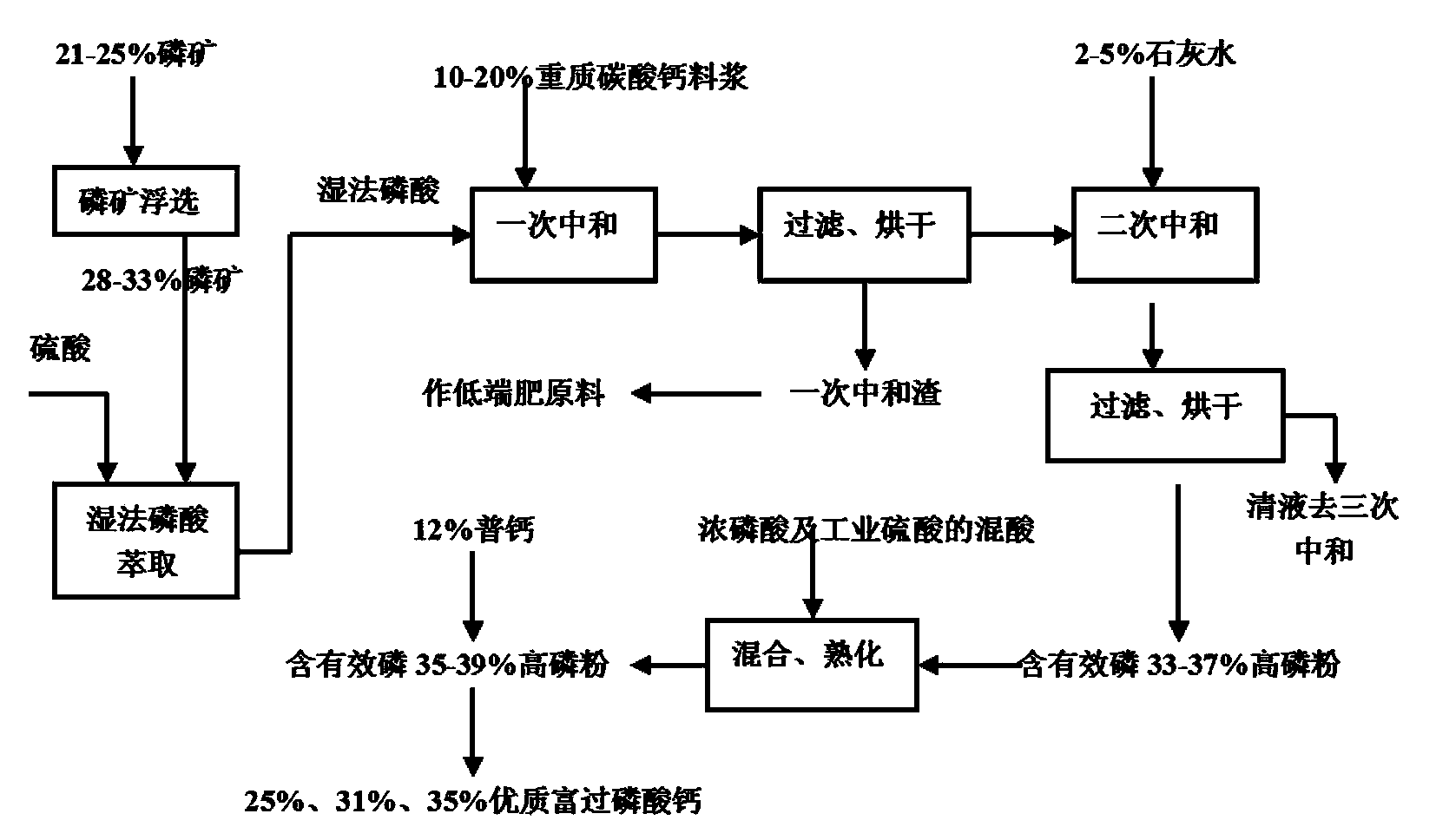

[0037] 1. Using 23.3% phosphate rock as raw material, 9.1% wet-process phosphoric acid is prepared after flotation and selection of magnesium. According to the technology of the present invention, one stage of primary heavy calcium is neutralized to pH 1.6, and then a second stage of lime neutralization is performed. To pH 2.1, prepare high-phosphorus powder with 34.2% available phosphorus;

[0038] 2. Add 18.6 parts of phosphoric acid containing 42.5% phosphorus pentoxide and a mixed acid of sulfuric acid (concentrated phosphoric acid with 6% sulfuric acid) for every 100 parts of high phosphorus powder to prepare high phosphorus fertilizer containing 35.5% of available phosphorus;

[0039] 3. Add 74.5 parts of ordinary calcium containing 12.3% of available phosphorus to 100 parts of the high-phosphate fertilizer prepared in the previous step, and the prepared superphosphate-rich calcium has an effective phosphorus content of 25.6%, water-soluble phosphorus 16.6%, and a free acid co...

Embodiment example 2

[0041] 1. Using 23.9% phosphate rock as raw material, 10.2% wet-process phosphoric acid is prepared after flotation and selection of magnesium. According to the technology of the present invention, the pH value of the first heavy calcium is 1.7, and then the second lime is added. And to pH 2.3, prepare high phosphorus powder with 35.8% available phosphorus;

[0042] 2. For every 100 parts of high phosphorus powder, add 34.1 parts of a mixed acid of phosphoric acid and sulfuric acid containing 41.3% phosphorus pentoxide (9% sulfuric acid is added to concentrated phosphoric acid) to prepare high phosphorus fertilizer with 37.2% available phosphorus;

[0043] 3. Add 30.3 parts of ordinary calcium containing 12.3% effective to 100 parts of the high-phosphorus fertilizer prepared in the previous step, and the prepared superphosphate-rich calcium has an effective phosphorus content of 31.4%, water-soluble phosphorus 20.4%, and a free acid content of 6.6%. The product quality meets the te...

Embodiment example 3

[0045] 1. Using 24.6% phosphate rock as the raw material, the 11.5% wet-process phosphoric acid is prepared after flotation and selection of magnesium. According to the technology of the present invention, the pH value of the first heavy calcium is 1.9, and then the second lime is added. And to pH 2.4, prepare high phosphorus powder with 36.7% available phosphorus;

[0046] 2. For every 100 parts of high phosphorus powder, add 118.7 parts of a mixed acid of phosphoric acid and sulfuric acid containing 40.2% phosphorus pentoxide (12% sulfuric acid is added to concentrated phosphoric acid) to prepare high phosphorus fertilizer containing 38.6% of available phosphorus;

[0047] 3. Add 14.2 parts of ordinary calcium containing 12.1% of effective calcium to 100 parts of high-phosphorus fertilizer prepared in the previous step, and the prepared superphosphate-rich calcium has an effective phosphorus content of 35.3%, water-soluble phosphorus 22.5%, and a free acid content of 6.8%. The qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com